Multi-segment thermochromic temperature-regulating fabric

A thermochromic, fabric technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as limiting the scope of application, and achieve the effect of wide application fields, broad market application prospects, and outstanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

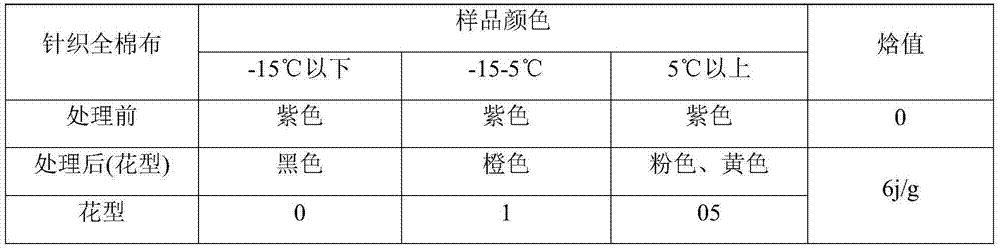

Embodiment 1

[0022] Preparation method of three-stage temperature-changing color temperature knitted cotton fabric rotary screen printing:

[0023] 6g of critical temperature is -15 ℃ and 5 ℃ three-stage temperature-sensitive color-changing pigment (color change is black, purple, powder, prepared by electron transfer type organic compound system, commercially available), 15g of phase-change temperature-regulating microcapsule powder (with tetradecane as the core and polystyrene as the core-shell structure microcapsules prepared by the shell, and then dried into powder), 25g of adhesive, 2g of thickener, 1g of dispersant and 51g of water are mixed thoroughly with a color paste mixer to prepare color paste;

[0024] Select purple knitted cotton fabric, and design the pattern into different numbers. According to the pattern design, make a patterned rotary screen, print it through the rotary screen printing machine, and then put the fabric into the drying room of the printing machine, and dry ...

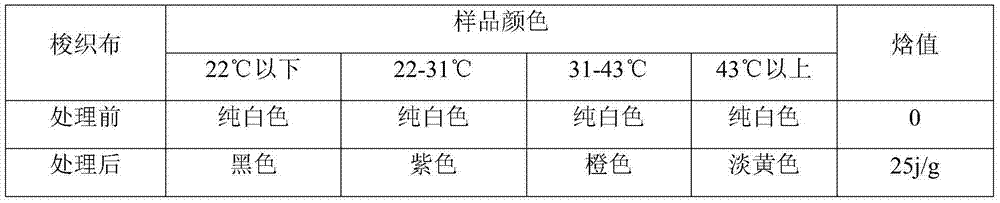

Embodiment 2

[0030] Four-stage temperature-changing color temperature woven pure white cloth flat screen printing preparation method:

[0031] 5g of four-stage thermochromic pigments with critical temperatures of 22°C, 31°C, and 43°C (commercially available), 30g of phase-change temperature-regulating microcapsule powder (with 30# and 35# paraffin as the core, polymethyl methacrylate The ester is the core-shell structure microcapsule emulsion prepared by the shell, and then dried into powder), 30g adhesive, 2g thickener, 1g dispersant and 32g water are mixed thoroughly with a color paste mixer to make a color paste;

[0032] Select a pure white woven fabric, print it on a flat screen, and then put the fabric into the drying room of the printing machine, and dry it at 130°C for 3 minutes.

[0033] Then measure the thermochromic property and enthalpy value of thermochromic and thermoregulatory fabrics, and the results are shown in Table 2.

[0034] Table 2 Thermochromic properties and entha...

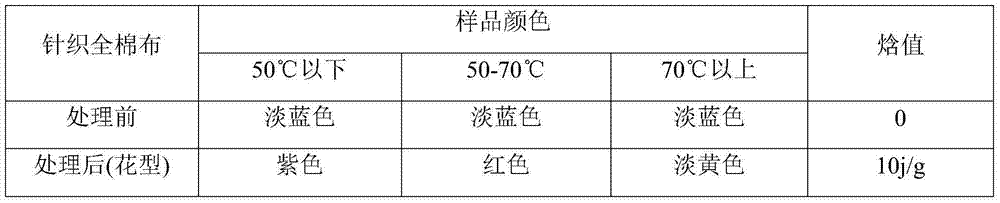

Embodiment 3

[0038] Three-stage temperature-sensitive color-changing color temperature light blue non-woven fabric rotary screen printing preparation method:

[0039] 3g critical temperature is 50 ℃ and 70 ℃ three-stage thermochromic pigment (commercially available), 20g phase change thermoregulation microcapsule powder (with behenyl alcohol as the core, melamine formaldehyde resin as the core shell prepared by the shell Structural microcapsule emulsion, after drying into powder), 20g adhesive, 2g thickener, 1g dispersant and 54g water are mixed thoroughly with color paste mixer, make color paste;

[0040] Select light blue cloth, make a patterned rotary screen according to the pattern design, print it through a rotary screen printing machine, and then put the fabric into the drying room of the printing machine, and dry it at 120°C for 5 minutes.

[0041] Then measure the thermochromic property and enthalpy value of thermochromic and thermoregulatory fabrics, and the results are shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com