A method for encapsulating a double-glass solar cell module

A technology of solar cells and encapsulation methods, applied to electrical components, circuits, photovoltaic power generation, etc., can solve the problems of high energy consumption and disadvantages, achieve low energy consumption, reduce the probability of fragments and hidden cracks, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

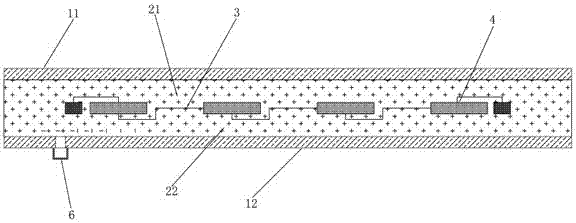

[0023] Embodiment 1: as figure 1 The double-glass solar cell module shown includes, from top to bottom, the first tempered glass layer 11, the first PVB layer 21, the battery pack layer 4, the bus bar, the second PVB layer 22 and the second tempered glass layer 12. Multiple cells of the battery pack layer 4 are formed by connecting tin-coated copper strips 3 in series end to end. The bus bars are arranged in segments along the cell edges of the module. The second tempered glass layer 12 corresponds to the opening of the bus bar segment. A round hole is provided, and the lead wire of the bus bar is drawn out from the round hole and connected with the terminal post of the split junction box 6 .

[0024] The specific production method is as follows: first, use an automatic welding machine to weld the battery sheets in series with tin-coated copper strips 3 to form a battery pack layer 4; use an automatic laying machine to arrange the battery pack layer 4 on the laid first tempere...

Embodiment 2

[0036] Embodiment 2: roughly the same as Example 1, the difference is that the preheating temperature is 70°C, the preheating time is 40 minutes, the vacuum pressure is 0.18Mpa, the vacuum time is 40 minutes, and the temperature of the autoclave is 115°C , time is 4 hours, pressure is 1.5Mpa.

Embodiment 3

[0037] Embodiment 3: roughly the same as Embodiment 1, the difference is that the preheating temperature is 50°C, the preheating time is 20 minutes, the vacuuming pressure is 0.22Mpa, and the vacuuming time is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com