Rapidly-dissolved Zhenju antihypertension tablet and preparation process thereof

A Zhenju Jiangya Tablet, dissolution technology, applied in the direction of medical preparations containing active ingredients, drug combinations, cardiovascular system diseases, etc., can solve the problems of complex process, difficult granulation, slow disintegration, etc., to achieve the preparation Simple process, good compressibility, rapid disintegration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

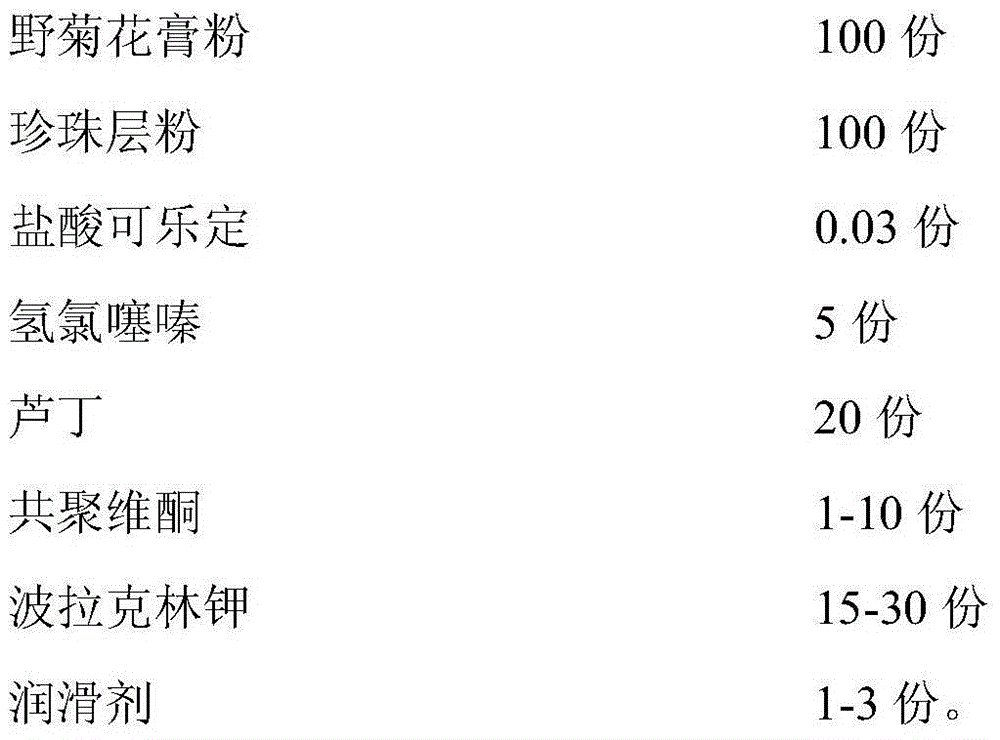

Embodiment 1

[0022]

[0023]

[0024] Preparation Process:

[0025] ①Add copovidone into purified water and stir until dissolved, then add hydrochlorothiazide and clonidine hydrochloride and stir until dissolved, and set aside; Spray the mixed solution prepared in step ① into the fluidized bed top spray method, granulate, set the inlet air temperature at 60°C, and the air volume at 100m 3 / h, atomization pressure 0.3MPa, after spraying, continue to dry for 30 minutes; ③ Weigh the dry granules prepared in step ②, add magnesium stearate and mix evenly, Φ9mm shallow arc punching tablets, control the average hardness 70-90N, and it is ready.

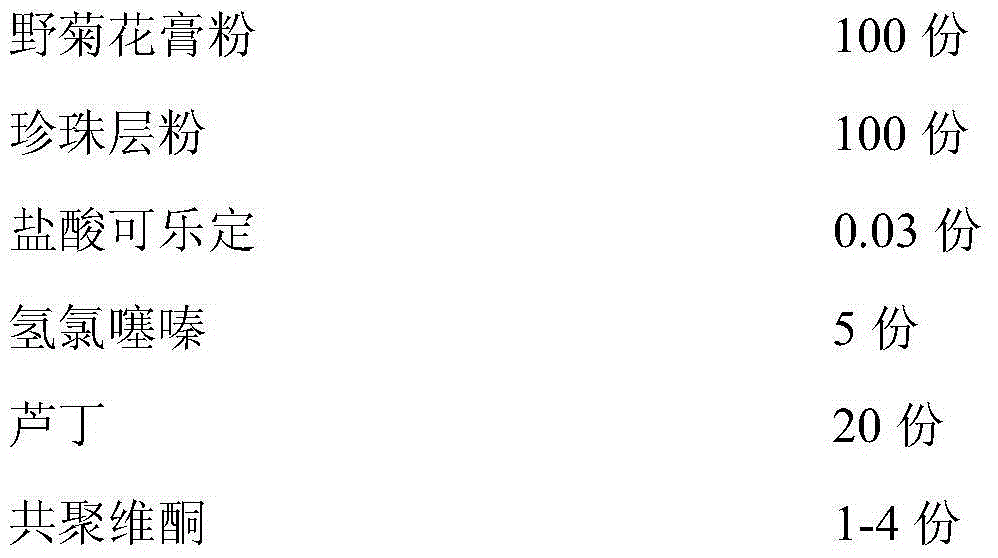

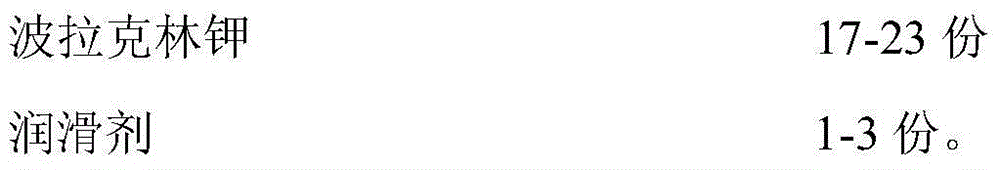

Embodiment 2

[0027]

[0028] Preparation Process:

[0029] ①Add copovidone into purified water and stir until dissolved, then add hydrochlorothiazide and clonidine hydrochloride and stir until dissolved, and set aside; Spray the mixed solution prepared in step ① into the fluidized bed top spray method, granulate, set the inlet air temperature at 60°C, and the air volume at 100m 3 / h, atomization pressure 0.3MPa, after spraying, continue to dry for 30 minutes; ③ Weigh the dry granules prepared in step ②, add magnesium stearate and mix evenly, Φ9mm shallow arc punching tablets, control the average hardness 70-90N, and it is ready.

Embodiment 3

[0031]

[0032]

[0033] Preparation Process:

[0034] ①Add copovidone into purified water and stir until dissolved, then add hydrochlorothiazide and clonidine hydrochloride and stir until dissolved, and set aside; Spray the mixed solution prepared in step ① into the fluidized bed top spray method, granulate, set the inlet air temperature at 60°C, and the air volume at 100m 3 / h, atomization pressure 0.3MPa, after spraying, continue to dry for 30 minutes; ③Weigh the dry granules prepared in step ②, add silicon dioxide, sodium stearate fumarate and mix evenly, Φ9mm shallow arc stamping sheet, control the average hardness 70-90N, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com