Annealing furnace flue gas denitration device and technology

A technology of annealing kiln and flue gas, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve the problems of ineffective control of annealing kiln flue gas, large investment in facilities, and high operating requirements, so as to ensure long-term normal operation Stable operation, low investment, fast denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but they are not used to limit the scope of the present invention.

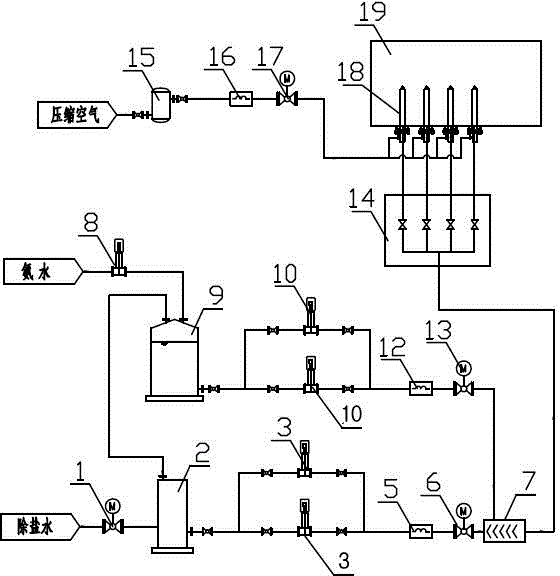

[0031] as attached figure 1 As shown, an annealing kiln flue gas denitrification device of the present invention includes an ammonia water system, a demineralized water system, a compressed air system, and an ammonia water spray system. Ammonia water pump 10 connected in parallel; the desalinated water system includes an electric valve 1, a desalinated water tank 2, and 2 parallel connected water pumps 3; The ammonia gas volatilized in the tank 9 enters the desalted water tank 2 and is absorbed by water to reduce ammonia escape. Mixer 7, distribution box 14, spray gun 18; There are multiple pipelines in the distribution box 14, each pipeline corresponds to a spray gun 18, and the ammonia water pump 10 and the water pump 3 are all connected with the mixer 7; the ammonia water pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com