Preparation method of high-silicon-oxygen composite felt

A technology of composite felt and high silicon oxygen, which is applied in the direction of chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problem that the tensile strength cannot meet the requirements, and achieve the widening of the application field and scope and high temperature resistance The effect of improving the tensile strength and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

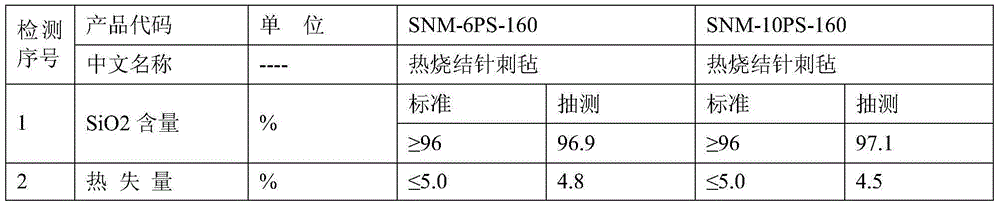

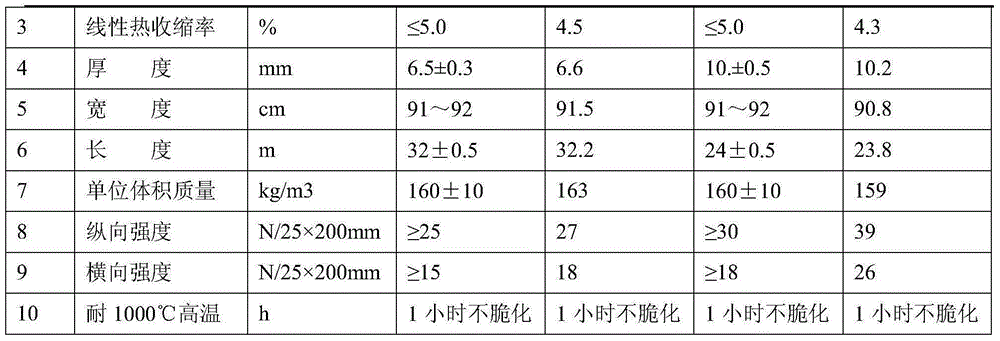

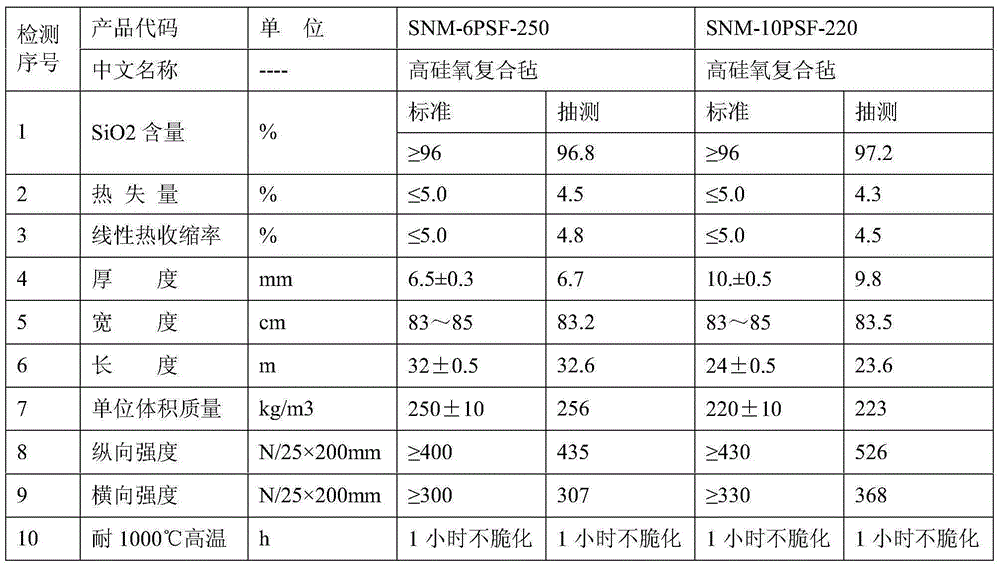

[0037] The present invention explains in detail the specific process of preparing the high silica composite felt through five specific examples.

[0038] In each embodiment, a high-silica composite felt was prepared by using a high-silica glass fiber mat continuous compound unit. The technical scheme of the high-silica glass fiber mat continuous composite unit is disclosed in the patent application document with application number 201420757783.3.

[0039] The high-silica glass fiber mat continuous composite unit includes an uncoiling mechanism, a gluing mechanism, a drying furnace and a winding mechanism, and is arranged in sequence according to the sequence of the uncoiling mechanism, the gluing mechanism, the drying furnace and the winding mechanism, and The centerline of the frame width direction of the uncoiling mechanism, the centerline of the frame width direction of the gluing mechanism, the centerline of the frame width direction of the gluing mechanism of the drying f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com