A staged low-temperature evaporation and concentrated lye device based on heat pump cycle

A technology of low-temperature evaporation and heat pump cycle, which is applied in the fields of alkali metal compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of stopping evaporation and slowing down the progress of evaporation and concentrated lye, so as to reduce operating costs and run The effect of low temperature and compact process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

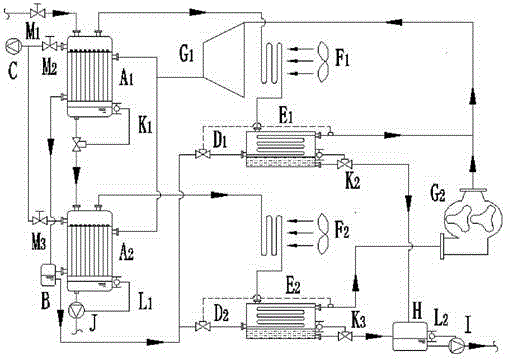

[0021] A kind of heat pump circulation-based device of the present invention for graded low-temperature evaporation and concentrated lye comprises three sub-loops: a heat pump circuit, an lye circuit, and a steam and condensed water circuit, wherein:

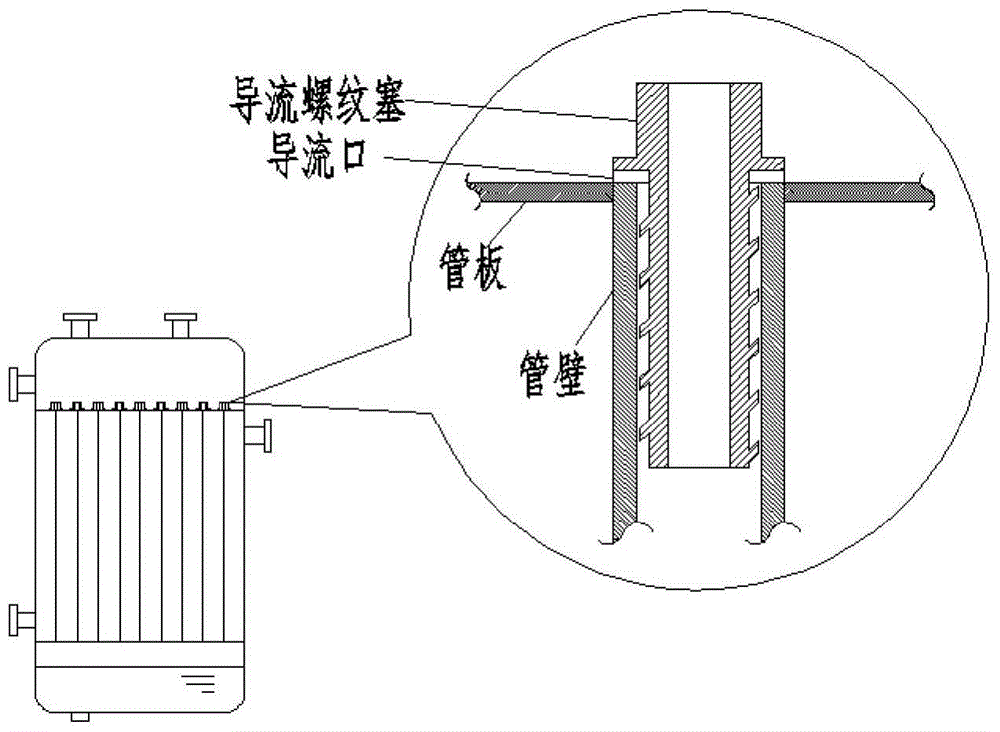

[0022] Heat pump circuit including low concentration lye evaporator A 1 , high concentration lye evaporator A 2 , refrigerant storage tank B, first thermal expansion valve D 1 , the second thermostatic expansion valve D 2 , refrigerant high pressure dry evaporator E 1 , Refrigerant low pressure dry evaporator E 2 , high pressure compressor G 1 , Roots blower G 2 ;Low concentration lye evaporator A 1 The outlet of the lower part of the refrigerant is connected to the upper inlet of the refrigerant storage tank B, and the high-concentration lye evaporator A 2 The outlet of the lower part of the refrigerant is connected to the upper inlet of the side of the refrigerant storage tank B, and the outlet of the lower part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com