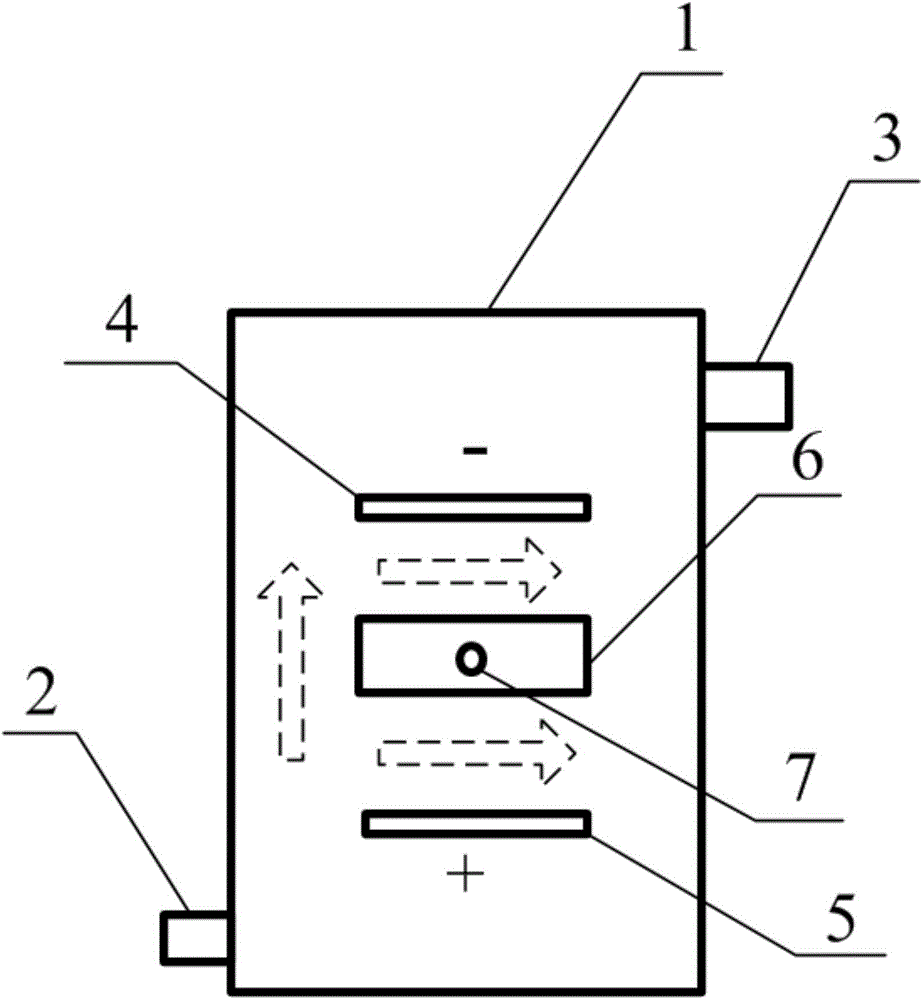

Electric flocculation and membrane separation water treatment device, treatment method and application of device

A technology of water treatment device and treatment method, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems such as the unification of electrocoagulation and membrane technology, and achieve good results Synergistic effect, optimization of membrane surface properties, effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Drinking water is treated

[0037] The TOC content in the drinking water to be treated is 15-16ppm.

[0038] The process is as follows:

[0039] (1) Pass the drinking water waste water from the water inlet 2, start the electrochemical device, and set the current density to 250A / cm 2 , the electric field strength is 55V / cm, the pressure is 75kPa, and the electrocoagulation process is carried out;

[0040] (2) After electrocoagulation for a period of time, start the suction filter pump for membrane filtration;

[0041] (3) Adjust the flow rate of the water outlet 7 of the water collection pipe to 325L / (h×m 2 ), monitor the concentration of pollutants in the outlet water of the water collection pipe outlet 7 until the outlet water reaches the standard.

[0042] After testing, the TOC content in the water effluent from the outlet 7 of the water collection pipe obtained after treatment is about 0.5 ppm, and the separation efficiency of pollutants is 95%.

[0...

Embodiment 2

[0044] Embodiment 2: Industrial sewage is processed

[0045] The TOC content in the industrial sewage to be treated is 18-20ppm.

[0046] In addition to setting the current density in step (1), the processing process is 350A / cm 2 , the electric field intensity is 76V / cm, and the pressure is 90kPa. In step (3), the flow rate of water outlet 7 of the water collecting pipe is adjusted to be 300L / (h×m 2 ) except that other processes are the same as in Example 1.

[0047] After testing, the TOC content in the water effluent from the outlet 7 of the water collection pipe obtained after treatment is less than 1ppm, and the separation efficiency of pollutants is 94.9%.

Embodiment 3

[0048] Embodiment 3: Industrial sewage is processed

[0049] The TOC content in the industrial sewage to be treated is 10-15ppm.

[0050] In addition to setting the current density in step (1), the processing process is 500A / cm 2 , the electric field intensity is 100V / cm, and the pressure is 90kPa. In step (3), the flow rate of water outlet 7 of the water collecting pipe is adjusted to be 340L / (h×m 2 ), other processes are the same as in Example 1.

[0051] After testing, the TOC content in the effluent water from the outlet 7 of the water collection pipe obtained after treatment is about 0.5 ppm, and the separation efficiency of pollutants is 95.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com