Preparation method for growing TiO2NWs on surfaces of carbon fibers in supercritical water

A technology of surface growth and supercritical water, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of damage to the strength of carbon fiber body, cumbersome operation, and difficult implementation, so as to achieve strength without damage, environmental pollution, and easy The effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

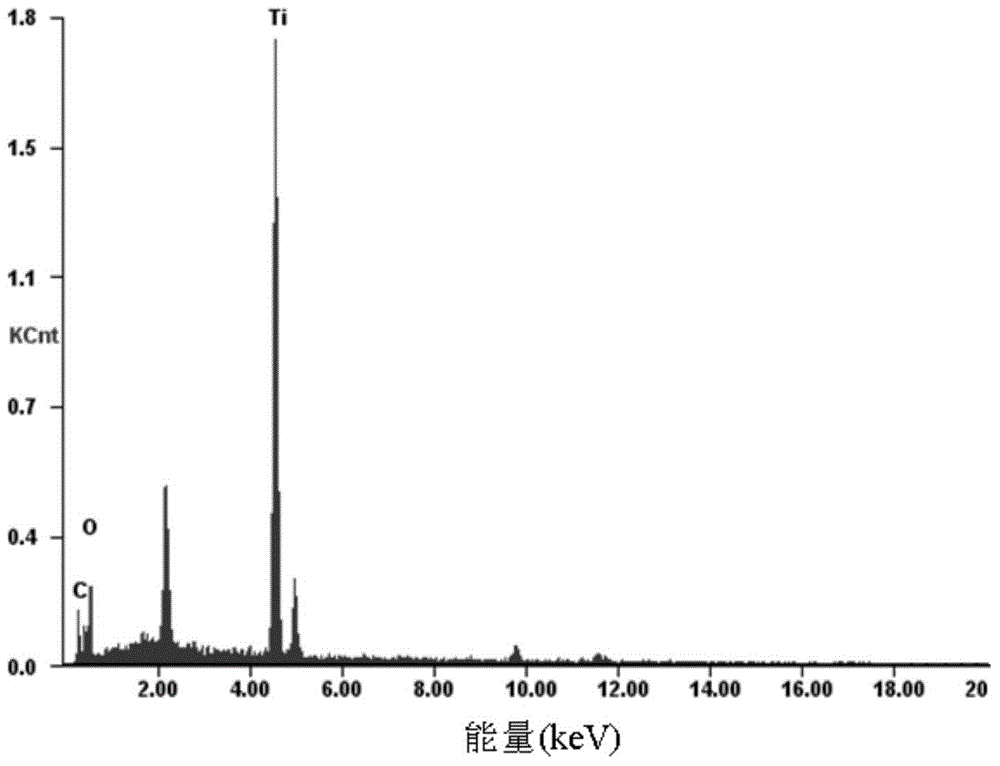

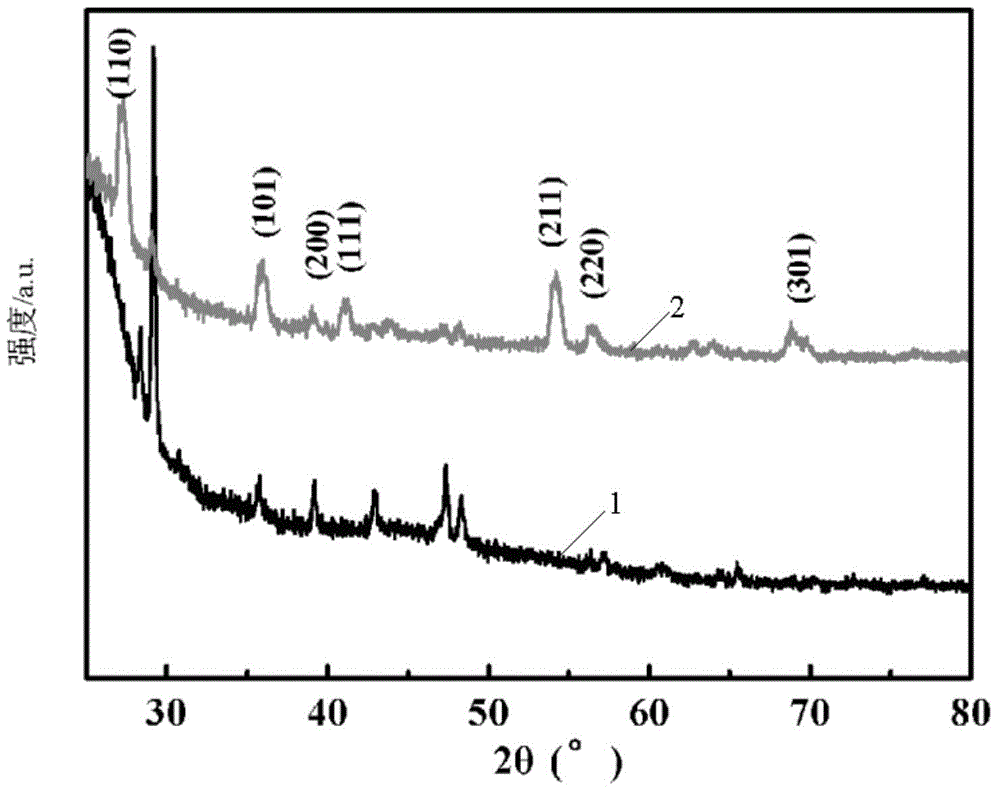

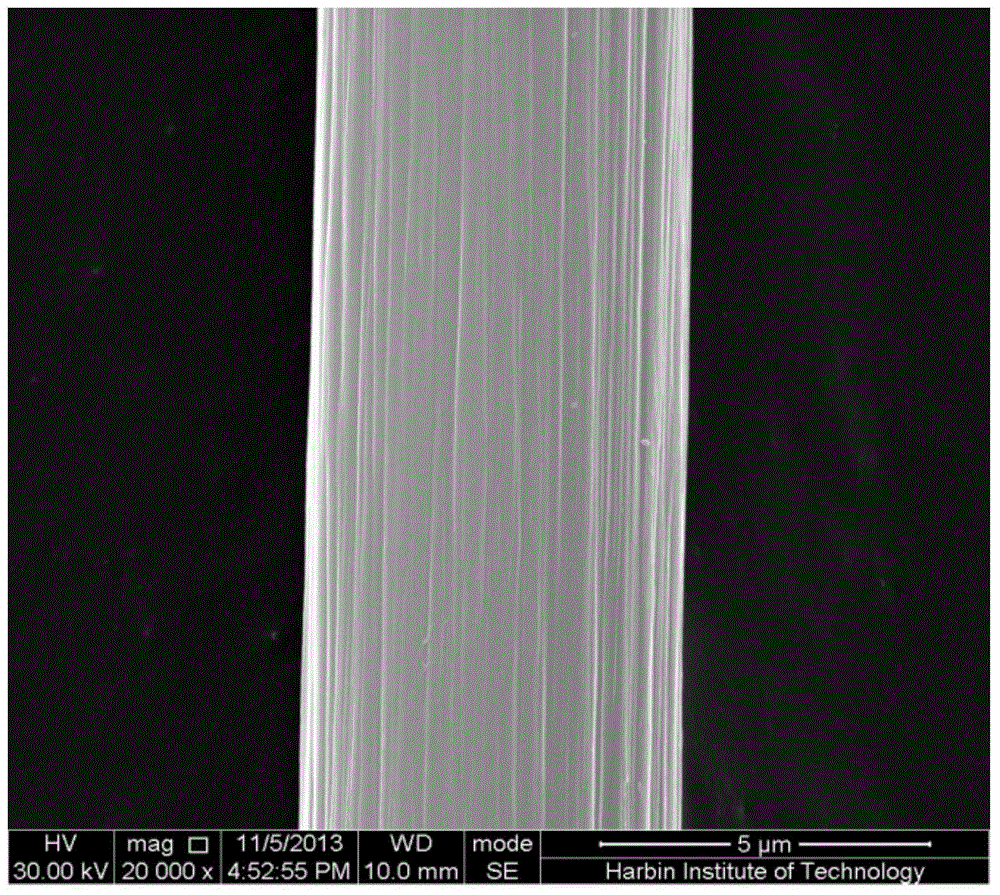

[0054] Specific implementation mode 1: This implementation mode is a method of growing TiO on the surface of carbon fibers in supercritical water. 2 The preparation method of NWs is accomplished according to the following steps:

[0055] 1. Preparation of TiO 2 Sol: Add tetrabutyl titanate to absolute ethanol, then add diethanolamine, and stir at a stirring speed of 5r / min~10r / min for 0.5h~2h to obtain reaction solution A; the mass fraction is 1% ~2% polyethylene glycol aqueous solution was added dropwise to the reaction solution A at a rate of 1 drop / min~3 drops / min, and then stirred at a stirring speed of 5r / min~10r / min for 5h~10h to obtain a transparent TiO 2 Sol;

[0056] The volume ratio of absolute ethanol and tetrabutyl titanate described in step 1 is (1.25~10):1;

[0057] The volume ratio of absolute ethanol described in step 1 to diethanolamine is (6~60):1;

[0058] The mass fraction of the polyethylene glycol described in step 1 is 1%-2%, and the volume ratio of...

specific Embodiment approach 2

[0092] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of absolute ethanol to tetrabutyl titanate in step 1 is (1.25-5):1. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0093] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of absolute ethanol to tetrabutyl titanate in Step 1 is (5-10):1. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com