A Method for Strengthening Metal Pipe Joints Using Fiber Reinforced Composite Materials

A fiber-reinforced, composite material technology, used in building maintenance, construction, building construction, etc., can solve problems such as lack of research and design, late start, etc., to achieve the effects of beautiful node appearance, improved stiffness, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

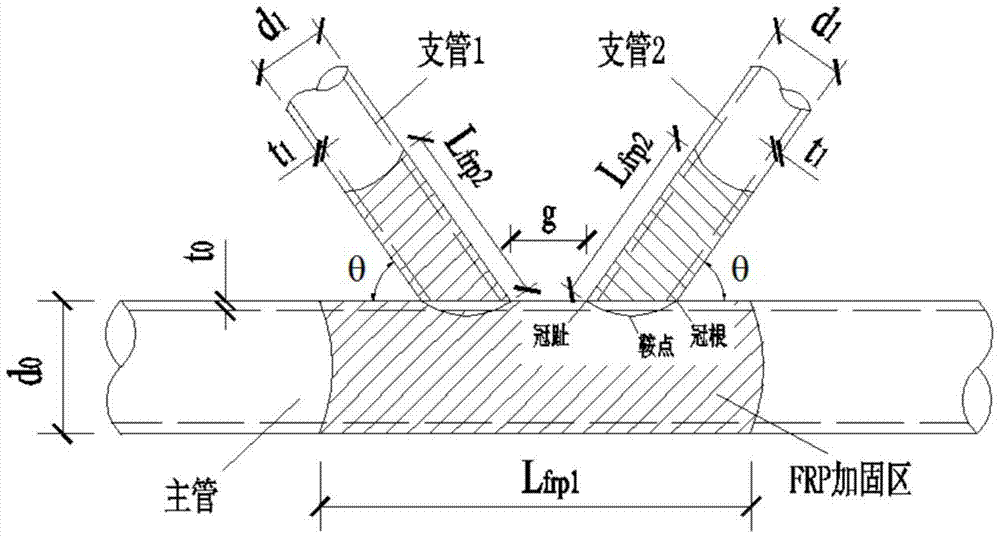

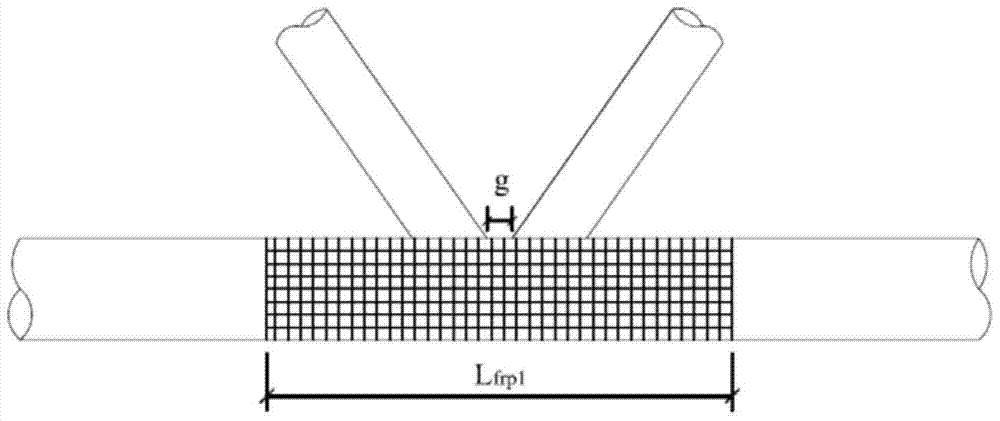

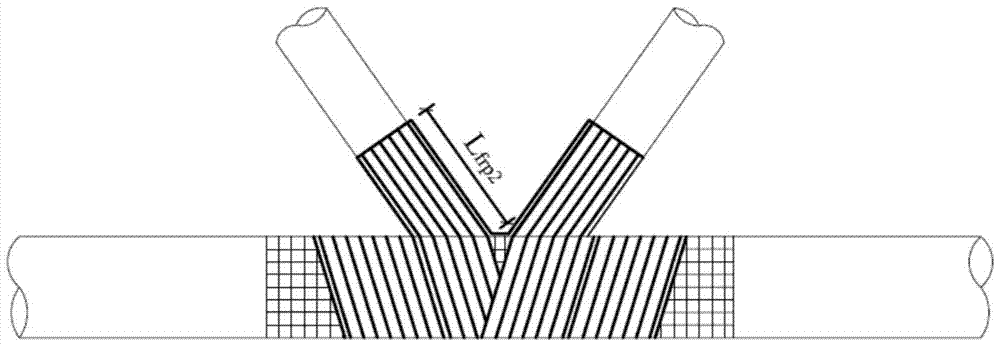

[0065] Reinforcement of circular steel tube K-shaped gap joints with carbon fiber reinforced polymer (Carbon Fiber Reinforced Polymer, CFRP)

[0066] figure 1 It is a structural schematic diagram of a K-shaped gap node of a circular tube reinforced with a fiber-reinforced composite material according to an embodiment of the present invention. The reinforcement object is a round steel pipe K-shaped gap node, the size of the main pipe is Φ219mm×8mm, the diameter of the branch pipe is Φ133mm×6mm, the angle θ between the main pipe and the branch pipe is 55°, and the gap length g of the node domain is 40mm. The steel used for the nodes is Q235B.

[0067] First, surface treatment is carried out on the joints of steel pipes, and then adhesive is laid for reinforcement; the surface treatment is shot blasting, the purpose is to remove the rust layer, and make the surface rough to facilitate the adhesion of the adhesive layer; for places with more local oil pollution, use acetone to de...

Embodiment 2

[0102] Reinforcement of round aluminum tube K-shaped lap joints with glass fiber reinforced polymer (Glass Fiber Reinforced Polymer, GFRP)

[0103] Figure 23 It is a structural schematic diagram of a K-shaped lap joint of a circular tube reinforced with a fiber-reinforced composite material according to an embodiment of the present invention. The reinforcement object is a K-shaped lap joint of a round aluminum tube. The size of the main pipe is Φ200mm×6mm, the diameter of the branch pipe is Φ167mm×6mm, the angle θ between the main pipe and the branch pipe is 60°, and the lap rate Ov is 40%. Therefore, the lap length q is 77mm (take the gap length g as -77mm). The aluminum used for the nodes is 6061-T6.

[0104] First, surface treatment is carried out on the metal pipe joints, and then adhesive is laid for reinforcement; the surface treatment is shot blasting, the purpose is to remove the rust layer, and make the surface rough to facilitate the adhesion of the adhesive layer...

Embodiment 3

[0128] Reinforcement of round steel tube Y-shaped joints with carbon fiber reinforced polymer (Carbon Fiber Reinforced Polymer, CFRP)

[0129] Figure 24 It is a structural schematic diagram of a round tube Y-shaped node reinforced with a fiber-reinforced composite material according to an embodiment of the present invention. The reinforcement object is a Y-shaped joint of a round steel pipe, the size of the main pipe is Φ245mm×10mm, the diameter of the branch pipe is Φ180mm×8mm, and the angle θ between the main pipe and the branch pipe is 45°. Since the Y-shaped joint has only one branch pipe, it can be approximately considered as a special case of the K-shaped joint—the two branch pipes overlap each other, so the lap length can be approximately considered as the projected length of the branch pipe diameter on the main pipe axis (take the gap length g =-d / sinθ=-180 / sin45°=-255). The steel used for the nodes is Q235B.

[0130] First, surface treatment is carried out on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com