A horizontal chain grate heat medium furnace coupled with side wall grading air and flue gas recirculation

A flue gas recirculation, chain grate technology, applied in lighting and heating equipment, heat storage heaters, fluid heaters, etc. Combustion intensity, the effect of solving excessive NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

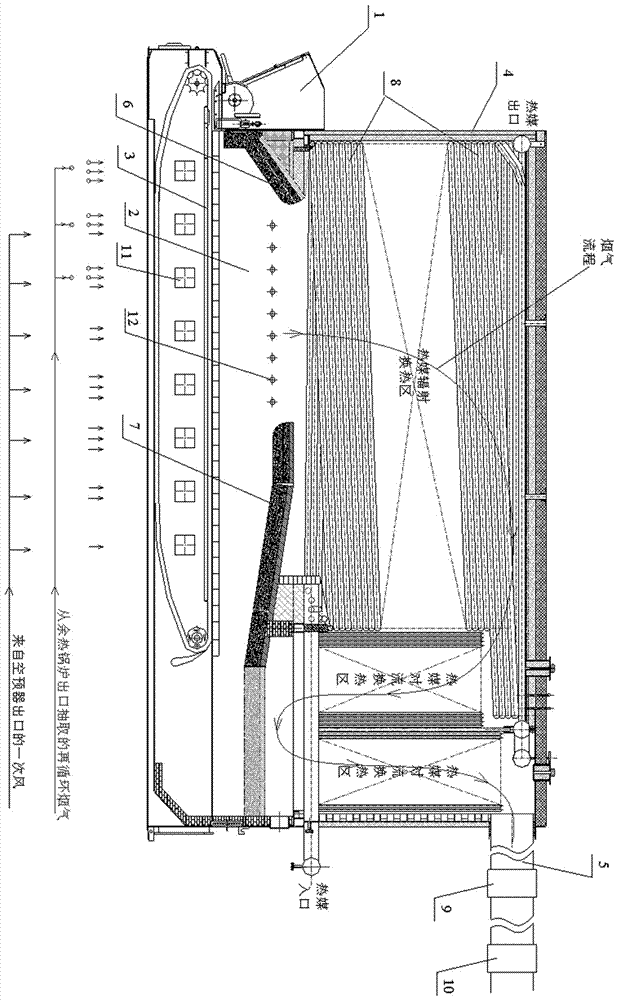

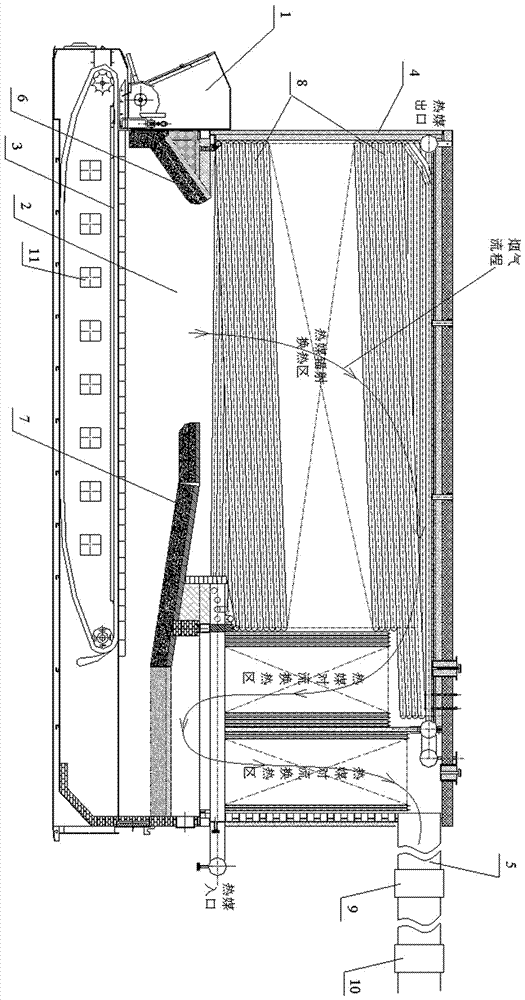

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] like figure 1 As mentioned above, the horizontal chain grate heat medium furnace of the present invention, which is coupled with side wall grading air and flue gas recirculation, is composed of scraper coal feeder 1, combustion chamber 2, chain grate 3, horizontal furnace body 4 and tail section. The flue 5 is composed; the combustion chamber 2 is surrounded by a short front furnace arch 6, a low and large-span rear furnace arch 7 and the chain grate 3; the horizontal furnace body 4 is located in the Above the combustion chamber 2, a large number of heat medium tube bundles 8 are arranged in the inner space, and are sequentially divided into a large space heat medium radiation heat exchange area and a small space heat medium convection heat exchange area along the flow direction of the flue gas; the tail flue 5 is successively The waste heat boiler 9 and the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com