An online measurement system for plate thickness based on laser ultrasonic

A measurement system, laser ultrasonic technology, applied in the direction of measuring device, using ultrasonic/sonic wave/infrasonic wave, adopting optical device, etc., can solve the problems of rough surface, unoptimistic equipment cost, large error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

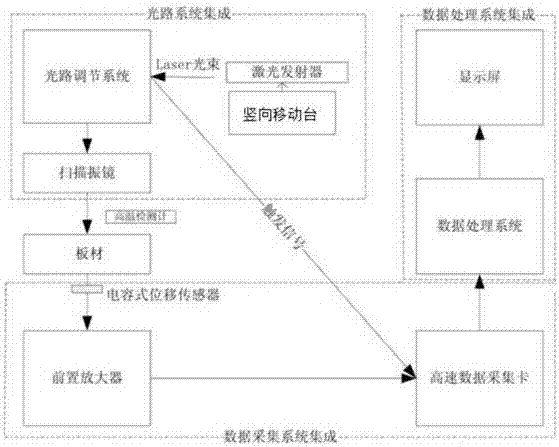

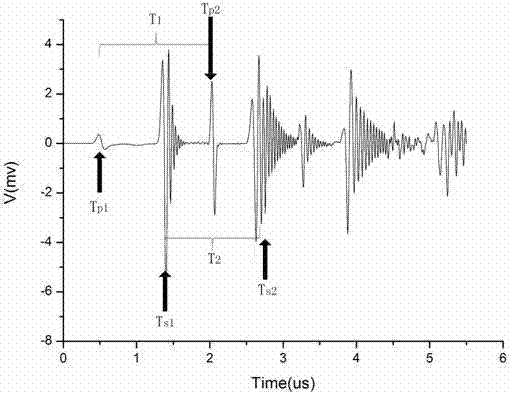

[0030] refer to Figure 1-7 : An on-line measurement system for plate thickness based on laser ultrasound, including optical path system integration, pyrometer, data acquisition system integration, and data processing system integration;

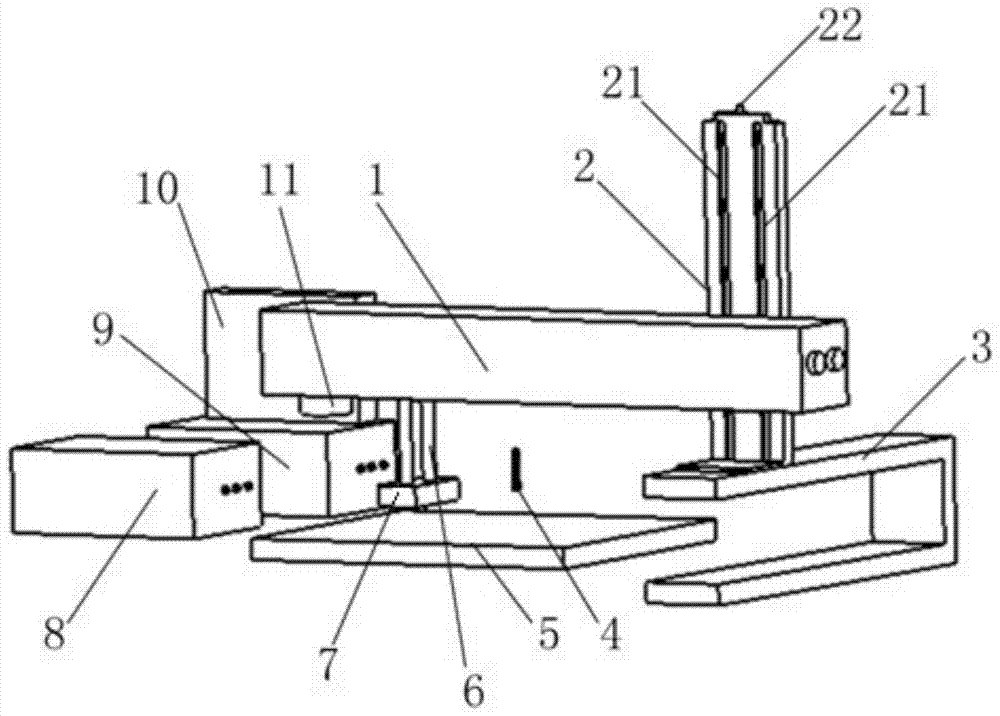

[0031]The optical path system integration includes a U-shaped ground frame 3, a vertical mobile platform 2, and a control cabinet 1 integrated with a laser transmitter, an optical path adjustment system and a scanning galvanometer 11, and the control cabinet 1 is fixed on the vertical On the mobile platform 23 of the mobile platform 2 to realize the vertical movement of the control cabinet 1, the vertical mobile platform 2 is fixed on the top of the U-shaped ground frame 3 by bolts, the opening of the U-shaped ground frame 3 is arranged horizontally, and the plate 5 Conveyed horizontally through the opening of the U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com