Intelligent power module and manufacturing method thereof

An intelligent power module, non-power technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of high switching loss, wire punching, and large distance between components, etc., to achieve dynamic power consumption reduction, The effect of reducing manufacturing cost and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

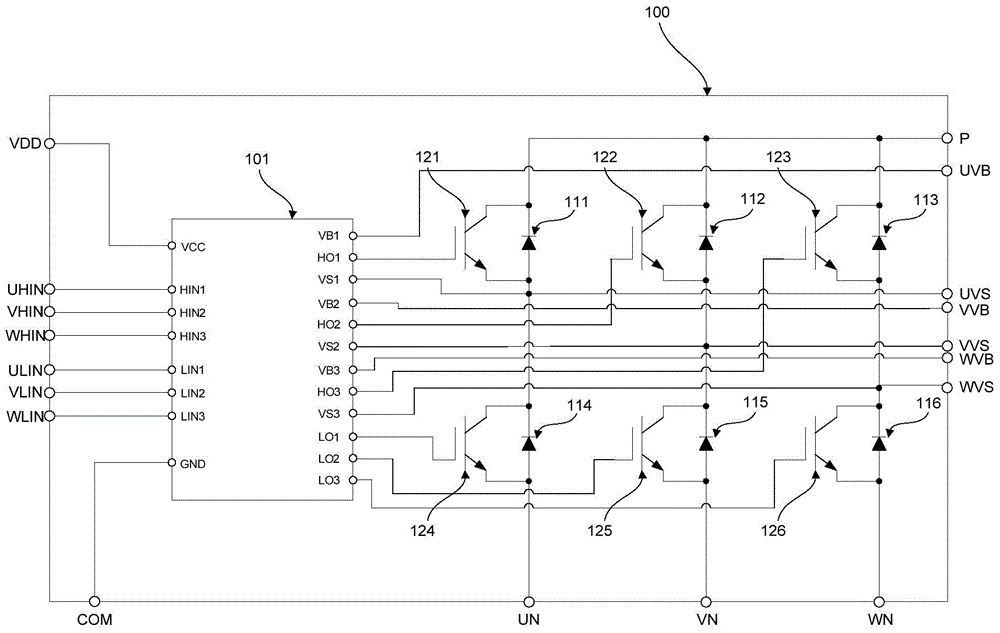

[0067] Referring to FIG. 2(A), it is a circuit diagram of a preferred embodiment of the intelligent function module of the present invention.

[0068] The U-phase high-voltage drive integrated tube 41, the V-phase high-voltage drive integrated tube 42, and the W-phase high-voltage drive integrated tube 43 in the intelligent function module proposed by the present invention are three single-arm HVIC tubes used to drive the upper bridge arm IGBT tube. The structure is exactly the same, the function is to transmit the logic signal of 0~5V at the input terminal HIN to the output terminal HO, where HO is the logic signal of VS~VS+15V; since VS will change between 0~300V, so the The U-phase high-voltage drive integrated tube 41, the V-phase high-voltage drive integrated tube 42, and the W-phase high-voltage drive integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com