Chinese herbal medicine residue recycling process

A technology for Chinese herbal medicine and medicinal residues, which is applied in the field of Chinese herbal medicine residues recovery technology, and can solve problems such as waste of medicinal residues ethanol or petroleum ether and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

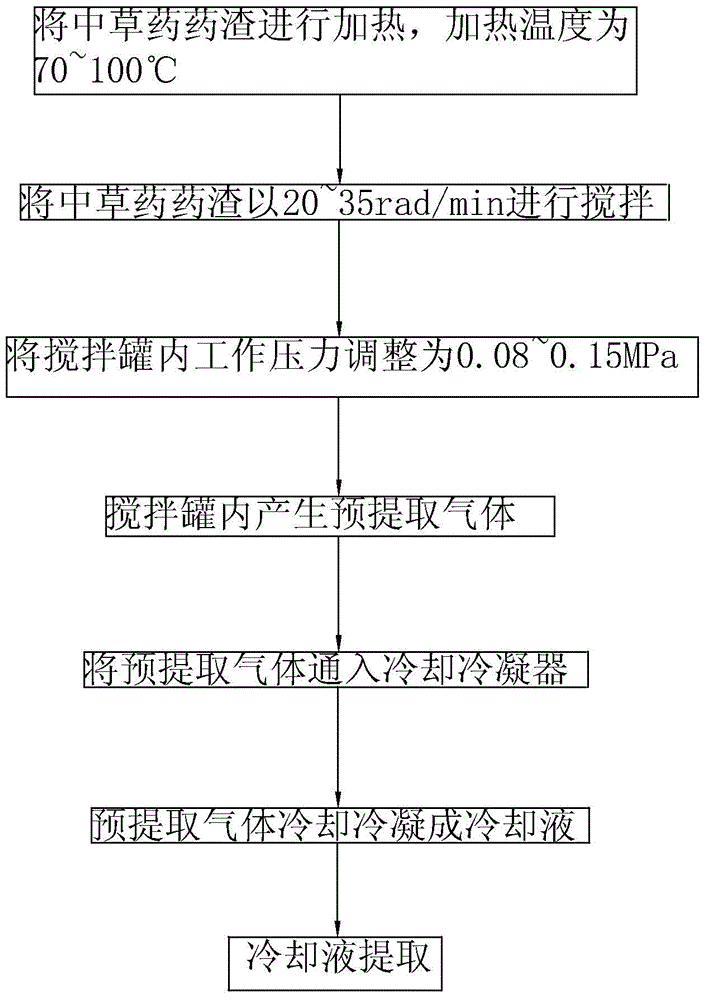

Image

Examples

Embodiment 1

[0036] Embodiment 1: In this embodiment, when extracting ethanol (ethanol liquid density is 0.789g / cm3(20C°), ethanol gas density is 1.59kg / m3, boiling point is 78.4 ℃, melting point is -114.3 ℃, flammable, its vapor can form an explosive mixture with air, and can be miscible with water in any ratio) or petroleum ether (the boiling range of petroleum ether is 60-90℃), the heating temperature in the stirring tank is 70℃ , the working pressure in the stirring tank is 0.08MPa, the stirring paddle in the stirring tank stirs the Chinese herbal medicine dregs at 20 rad / min, and the heating temperature in the stirring tank is set to 70°C, with the Chinese herbal medicine dregs at this temperature Continue heating, and cooperate with the working pressure in the stirring tank to be 0.08MPa and the stirring paddle to stir the Chinese herbal medicine dregs at 20 rad / min, so that when the Chinese herbal medicine dregs are stirred at a lower stirring speed, the temperature in the stirring t...

Embodiment 2

[0037] Embodiment 2: In this embodiment, when extracting ethanol or petroleum ether from Chinese herbal medicine dregs, the heating temperature in the stirring tank is set to 100°C, the working pressure in the stirring tank is 0.15MPa, and the stirring paddle in the stirring tank Stir the Chinese herbal medicine dregs at 35 rad / min, and control the heating temperature at 100°C, so that ethanol or petroleum ether can be volatilized or evaporated from the Chinese herbal medicine dregs relatively quickly, and the stirring blade is stirred at 35 rad / min, which improves the The heating uniformity of Chinese herbal medicine dregs, but too high temperature and too fast speed may lead to waste of power resources, and too high temperature may cause other impurities in the evaporated ethanol or petroleum ether.

[0038]As preferred in the following examples, the stirring paddle stirs the Chinese herbal medicine dregs at 30rad / min, and according to the efficiency of stirring the added Chi...

Embodiment 3

[0039] Embodiment 3: In this embodiment, as a preference, when extracting ethanol from Chinese herbal medicine dregs, the heating temperature in the stirring tank is 80° C., and the working pressure in the stirring tank is 0.09 MPa. The temperature is controlled at 80°C because the boiling point of ethanol is 78.4°C at normal temperature and pressure. The production of water or other impurities in the mixture affects the extraction of the purity of ethanol from the residue of Chinese herbal medicine. The working pressure in the stirring tank is reduced to 0.09MPa, which can reduce the boiling point of ethanol or petroleum ether, so that the stirring tank can be heated during the heating process. The middle block reaches the boiling point of evaporation, thereby saving the power consumption required for heating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com