A kind of plasma sputtering coating method

A plasma and sputtering coating technology, applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc. Small surface roughness, improved sputtering efficiency, and reduced working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

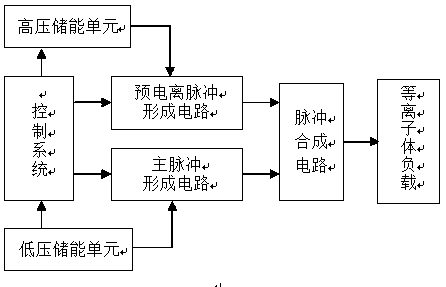

[0019] Such as figure 1 As shown, the new plasma sputtering coating device consists of a control system, a high-voltage energy storage unit, a low-voltage energy storage unit, a negative high-voltage pre-ionization pulse circuit, a low-voltage bipolar main pulse circuit, a pulse synthesis circuit and a plasma load. The control system is composed of touch screen, field programmable gate array (FPGA), programmable logic controller (PLC), isolation circuit and other peripheral circuits. The touch screen mainly realizes the setting of parameters such as the charging voltage of the high-voltage pre-ionization pulse and the high-power bipolar low-voltage main pulse, the output protection current, the pulse width of the optical signal, and the frequency of the optical signal, and controls the chargin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com