River sludge treatment device

A treatment device and river sludge technology, applied in sludge treatment, water/sludge/sewage treatment, fixed/solidified sludge treatment, etc., can solve the problems of river sludge treatment work, high sludge clay content and long time consumption and other problems, to achieve the effect of increasing the consolidation effect, buffering the vibration frequency, and increasing the safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

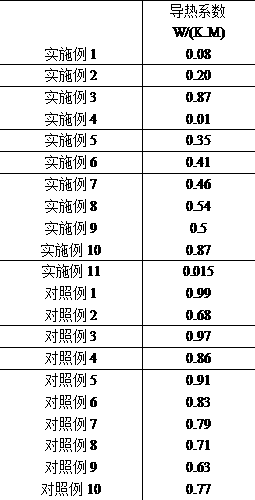

Embodiment 1

[0022] A method for preparing an inorganic heat insulation board material, characterized in that the method comprises the following steps:

[0023] Step 1. At room temperature, place 1 part of polypropylene fiber in 25 parts of deionized water for ultrasonic dispersion, then add 80 parts of modified silicate ceramic composite cement powder and 8 parts of water glass, and stir to obtain a mixed solution;

[0024] Step 2, adding 2 parts of hexamethylphosphoric triamide, 1 part of azodicarbonamide, and 1 part of ethylenediamine tetramethylene phosphonic acid to the above mixed solution and stirring evenly to obtain a geopolymer slurry;

[0025] Step 3, adding 5 parts of hydrogen peroxide, 0.5 parts of foaming catalyst sodium chlorate and 0.5 parts of foam stabilizer hexaglycerol monostearate into the geopolymer slurry, stirring for 3 minutes to obtain a foaming slurry;

[0026] Step 4, Stir the above-mentioned foaming slurry and put the mixture into the mold, add glass fiber mesh...

Embodiment 2

[0035] Step 1. At room temperature, place 1 part of polypropylene fiber in 25 parts of deionized water for ultrasonic dispersion, then add 70 parts of modified silicate ceramic composite cement powder and 8 parts of water glass, and stir evenly to obtain a mixed solution; the rest are prepared Same as Example 1.

Embodiment 3

[0037] Step 1. At room temperature, place 1 part of polypropylene fiber in 25 parts of deionized water for ultrasonic dispersion, then add 60 parts of modified silicate ceramic composite cement powder and 8 parts of water glass, and stir evenly to obtain a mixed solution; the rest are prepared Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com