Method for preventing bending deformation of hot-rolled cr-mo alloy steel pipe cooling bed

A bending deformation and alloy steel technology, applied in the field of hot-rolled steel pipe cooling, can solve the problems of bending deformation of the steel pipe body, uneven temperature drop of the pipe, and obstruction of online production, so as to reduce the bending deformation and ensure the uniformity of the temperature drop of the pipe. , the effect of reducing the effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

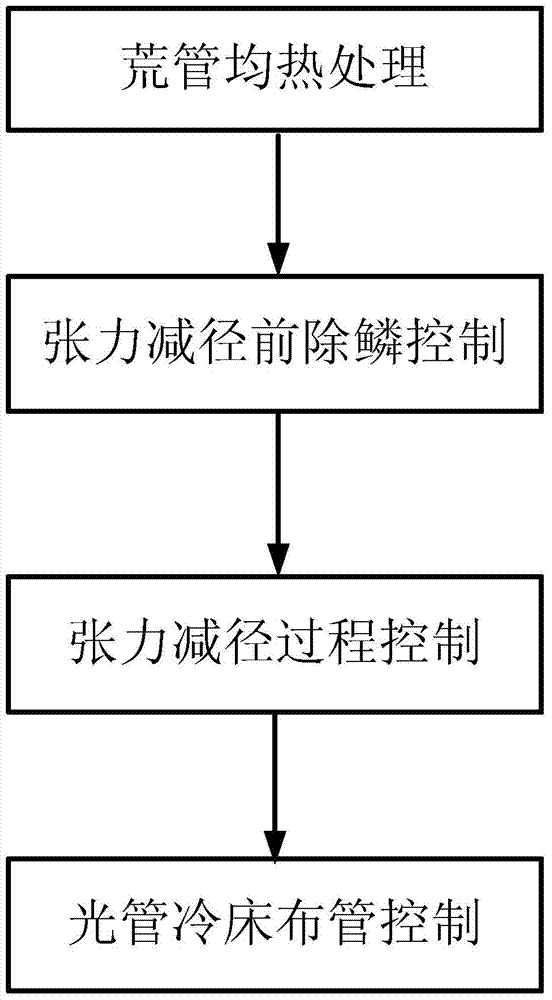

Method used

Image

Examples

Embodiment 1

[0046] Produce 30CrMo finished tubes with an outer diameter of 88mm and a length of 12m. The length of the head end and tail end of the smooth tube to be cut off later is 1.1m. The length of the hot-rolled barren tube is 14.2m. The tubes were ignited in 20 bypass burners in the reheating furnace, and after 31 minutes of heat treatment, the furnace temperature in the soaking section of the reheating furnace was raised to 800°C and kept at a constant temperature. After the capillary tube is hot-rolled into a waste tube, the waste tube enters the reheating furnace through the bypass roller table, and the waste tube is subjected to soaking treatment at a constant temperature for 0.5 minutes; the soaked tube is descaled with high-pressure descaling water. , the 1.1m head end and the 1.1m tail end of the waste pipe are not descaled; when the descaled waste pipe is tensioned and reduced on the stretching and reducing machine, the cooling of the empty rack that does not participate in ...

Embodiment 2

[0050]Produce 30CrMo finished pipes with an outer diameter of 100mm and a length of 15m. The length of the head end and tail end of the bare pipe to be cut off later is 2m. The length of the hot-rolled blank pipe is 19m. The hot-rolled blank pipe is 28 bypass burners were ignited in the reheating furnace, and after 45 minutes of heat treatment, the furnace temperature in the soaking section of the reheating furnace was raised to 1000°C and kept at a constant temperature. After the capillary tube is hot-rolled into a waste tube, the waste tube enters the reheating furnace through the bypass roller table, and the waste tube is subjected to soaking treatment at a constant temperature for 1.0 minutes; , the head end 2m part and the tail end 2m part of the waste pipe are not descaled; when the descaled waste pipe is tensioned and reduced on the stretching and reducing machine, the cooling water that does not participate in the metal rolling and passes through the stand is closed; A...

Embodiment 3

[0054] Produce 30CrMo finished tubes with an outer diameter of 139.7mm and a length of 12.7m. 25 bypass burners were ignited in the reheating furnace, and after 38 minutes of heat treatment, the furnace temperature in the soaking section of the reheating furnace was raised to 910°C and kept at a constant temperature. After the capillary tube is hot-rolled into a waste tube, the waste tube enters the reheating furnace through the bypass roller table, and the waste tube is subjected to soaking treatment at a constant temperature for 0.8 minutes; the soaked tube is descaled with high-pressure descaling water. , the 1.5m head end and the 1.5m tail end of the barren pipe are not descaled; an insertion frame with rolls is installed after the tensioning and reducing machine rolling frame, and the insertion frame is used as a guide frame, and the barren after descaling treatment When the tube is calibrated by the stretching and reducing machine to make a bare tube for output, the cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com