Three-dimensional printing molding device for rubber powder by microwave sintering

A microwave sintering and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of scorching, high viscosity, insufficient sintering, etc., and achieve the effect of saving powder, uniform fixed-point heating, and uniform powder spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

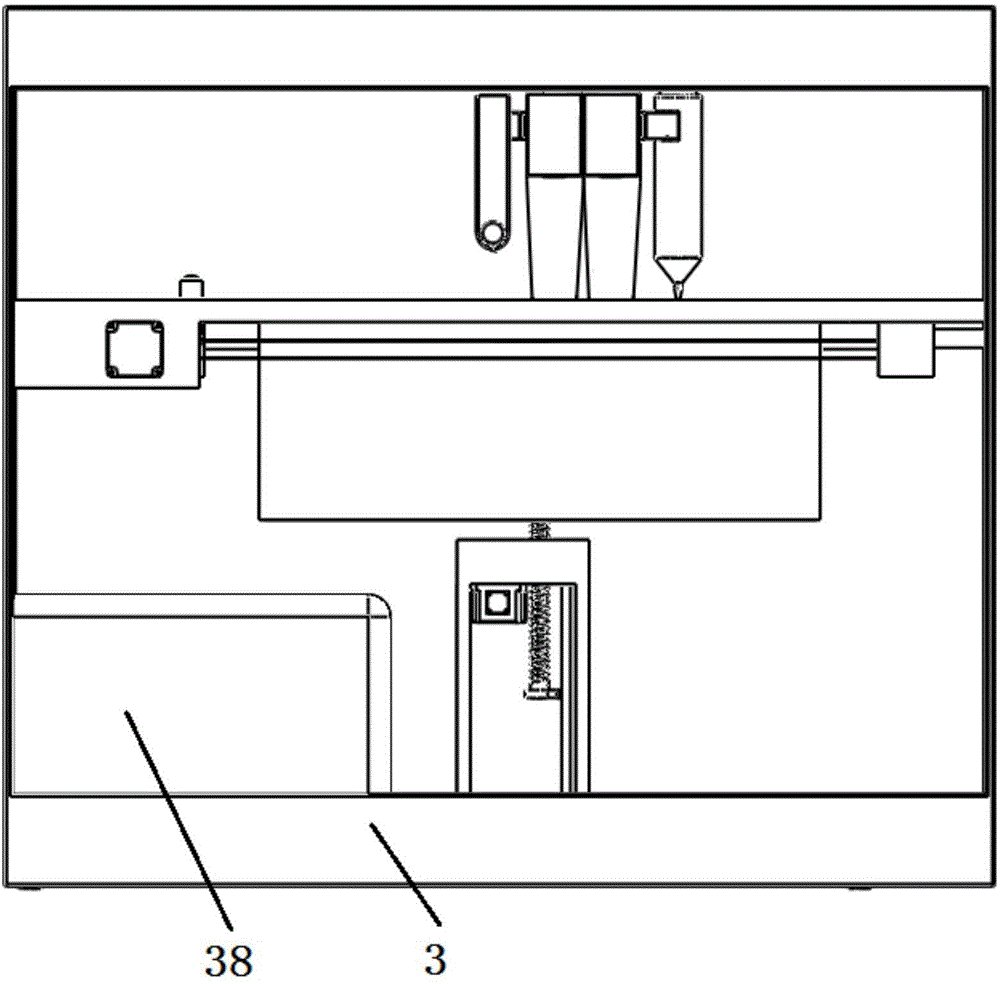

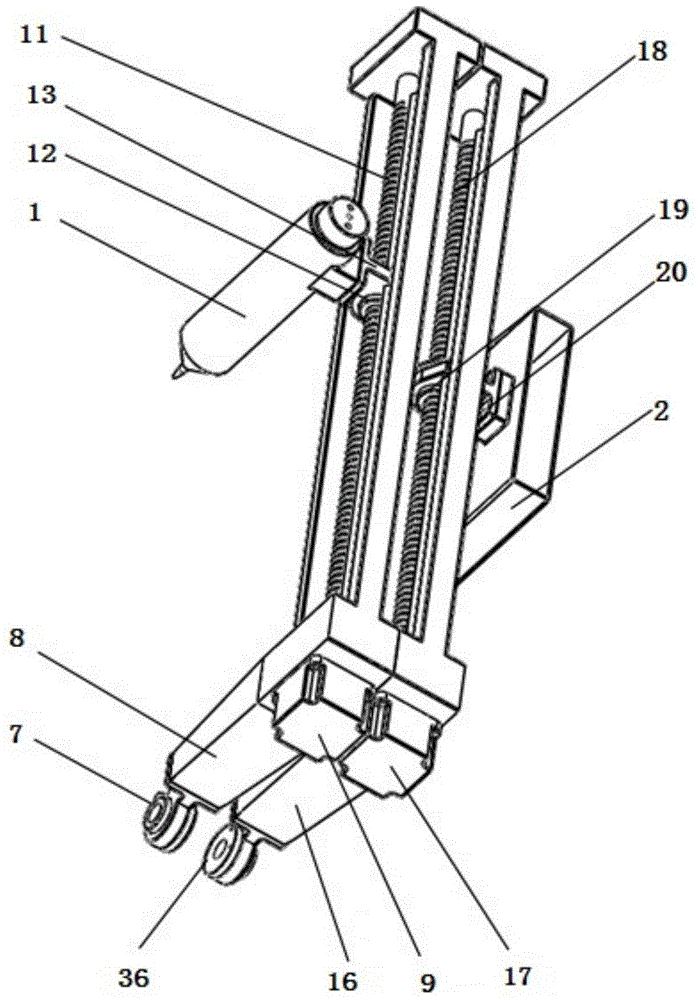

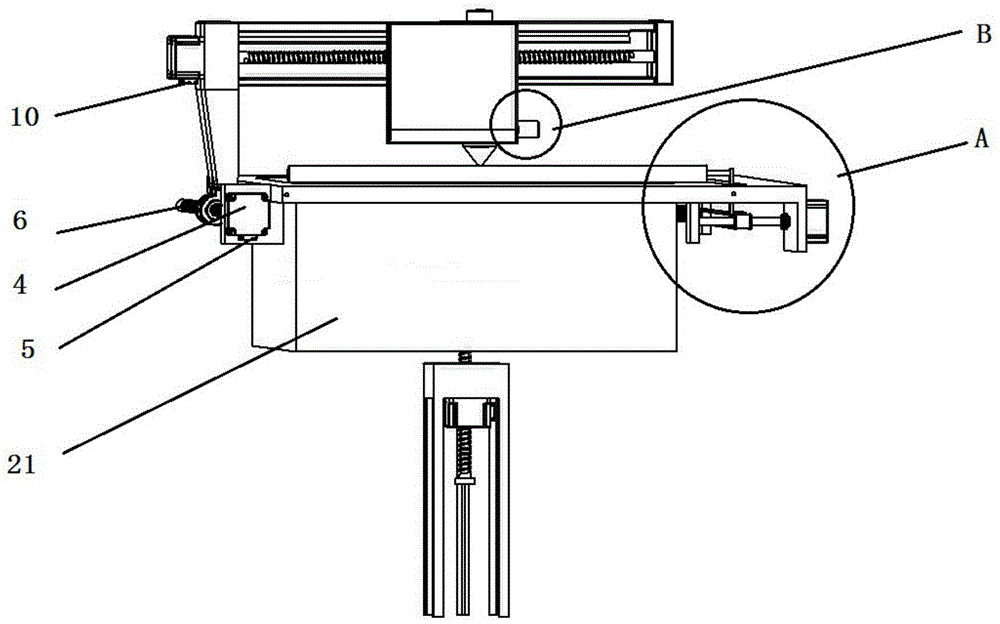

[0017] The invention provides a rubber powder microwave sintering 3D printing molding device, such as Figure 1-6 As shown, it includes a heating unit, a powder spreading unit and a control unit; wherein the heating unit includes a microwave knife 1 and a transmission part of the microwave knife, wherein the transmission part of the microwave knife includes an X-axis stepping motor 9, an X-axis driver 10, and an X-axis along the X-axis direction. Shaft screw A11, X-axis nut A12, microwave knife fixing part 13, including Y-axis stepping motor A4, Y-axis driver A5, Y-axis screw A6, Y-axis nut A7, support frame A8 along the Y-axis direction; The unit includes a powder box 2, a powder box transmission part, a working platform and a pressing roller. The powder box 2 is equipped with an arc-shaped baffle 14 and a solenoid valve 15, and the powder box transmission part includes an X-axis common motor 17 along the X-axis direction. , X-axis screw B18, X-axis nut B19, powder box fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com