Heat accumulating type lime rotary kiln

A technology of lime rotary kiln and regenerative type, which is applied in the field of regenerative lime rotary kiln and rotary kiln, which can solve the problems of limited energy recovery of preheating tubes and unfavorable production capacity, so as to achieve continuity and stability and expand production Abilities, effects that increase selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

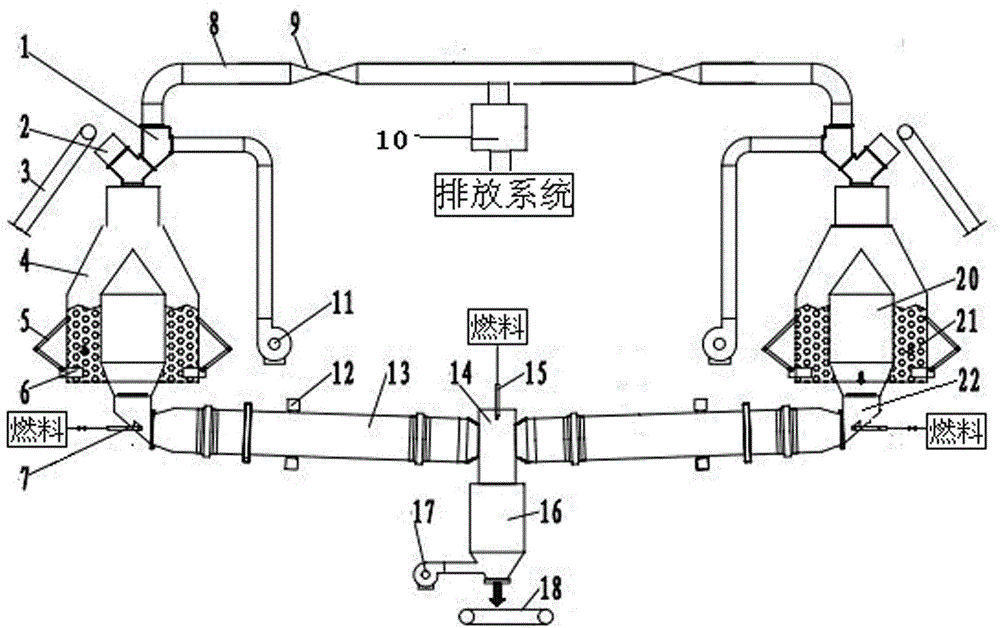

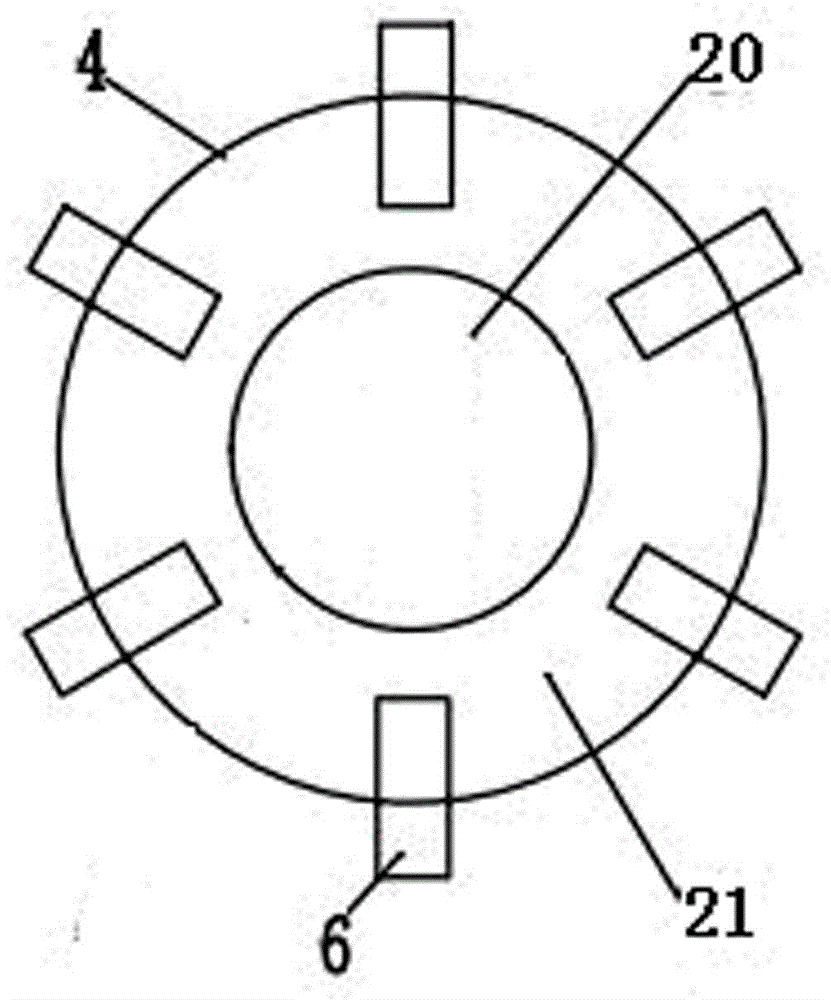

[0016] Regenerative lime rotary kiln of the present invention, such as figure 1 As shown, it includes two rotary kilns 13, cooler 16, two regenerators 4, feeding system 3, discharging system 18, blower 11, cooling fan 17, waste heat power generation equipment 10 and exhaust gas discharge system. The two rotary kilns are symmetrically arranged left and right, and are located on both sides of the kiln tail cover respectively. The rotary kiln is provided with a kiln head 22, and the two rotary kilns are connected to the cooler through the kiln tail cover 14, the cooler 16 is connected to the discharge system, and the cooling fan is connected to the cooler. The feed port on the upper part of the regenerator 4 is connected with the feeding system 3 through the feed valve 2 . The two heat accumulators 4 are sleeve-type structures, such as image 3 As shown, the heat accumulator 4 includes an outer cylinder and an inner cylinder 20, the upper part of the inner cylinder is a conical...

Embodiment 2

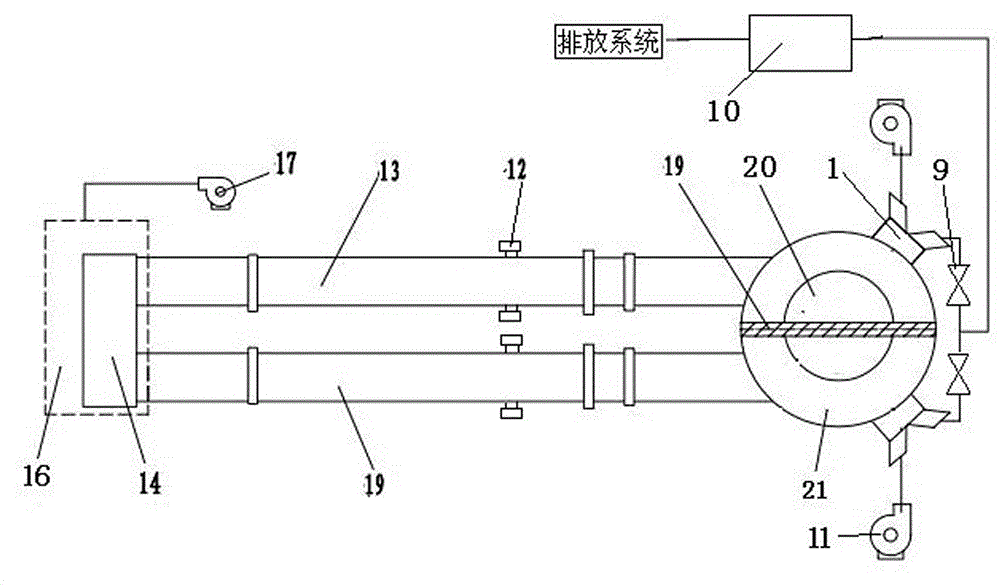

[0019] Another embodiment of the present invention is as figure 2 and Figure 4 As shown, the regenerative lime rotary kiln includes two rotary kilns 13 and one heat accumulator 4, the heat accumulator 4 is provided with a partition 19, and the partition divides the heat accumulator 4 into two parts with the same structure. One end of the two rotary kilns 13 is connected to the cooler 16 through the kiln tail cover 14 , and the other end is connected to the heat accumulator 4 . The two rotary kilns 13 alternately carry out calcination and preheating, and the material spaces on both sides of the regenerator partition 19 alternately store heat and release heat to preheat the air, which is realized by the action of the three-way valve 1, valve 9 and feed valve 3. Alternate operation, the set temperature of flue gas discharge is 160°C. Other equipment and connection status are the same as in Embodiment 1. The advantage of this embodiment is that the device is compact and saves...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap