Method for preparing zeaxanthin through in situ enrichment

A technology for in-situ enrichment of zeaxanthin, applied in natural dyes, chemical instruments and methods, azo dyes, etc., can solve problems such as limited zeaxanthin resources, achieve good application prospects, reduce usage, and eye fatigue Mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Using wolfberry fruit as raw material, zeaxanthin was prepared according to the following process:

[0048] Take wolfberry fruit, freeze-dry, grind into powder, pass through a 100-mesh sieve, take 1000 grams of powder under the sieve, add 10 liters of ethyl acetate according to the ratio of wolfberry fruit mass:solvent volume=1g:10ml, stir and extract at 30°C for 2 hours, extract After the end, let it stand for precipitation and separation; obtain the extract and filter residue;

[0049] Add 10 liters of ethyl acetate to the filter residue again for the second extraction; stir and extract at 30°C for 2 hours; after the extraction, let it stand for precipitation and separation; obtain the extract and filter residue;

[0050] The extraction was repeated 3 times; the combined extracts were concentrated in vacuum until the organic solvent evaporated, then 5 liters of 10% KOH ethanol solution was added, and stirred and saponified at 30°C for 20 hours;

[0051] After the sap...

Embodiment 2

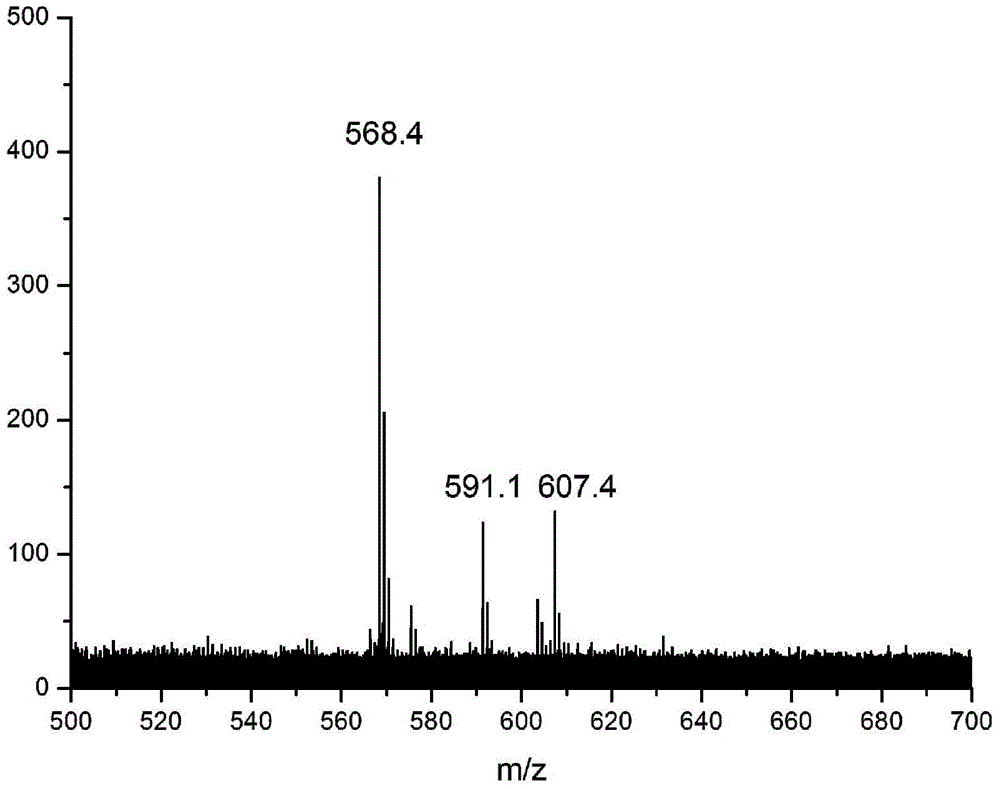

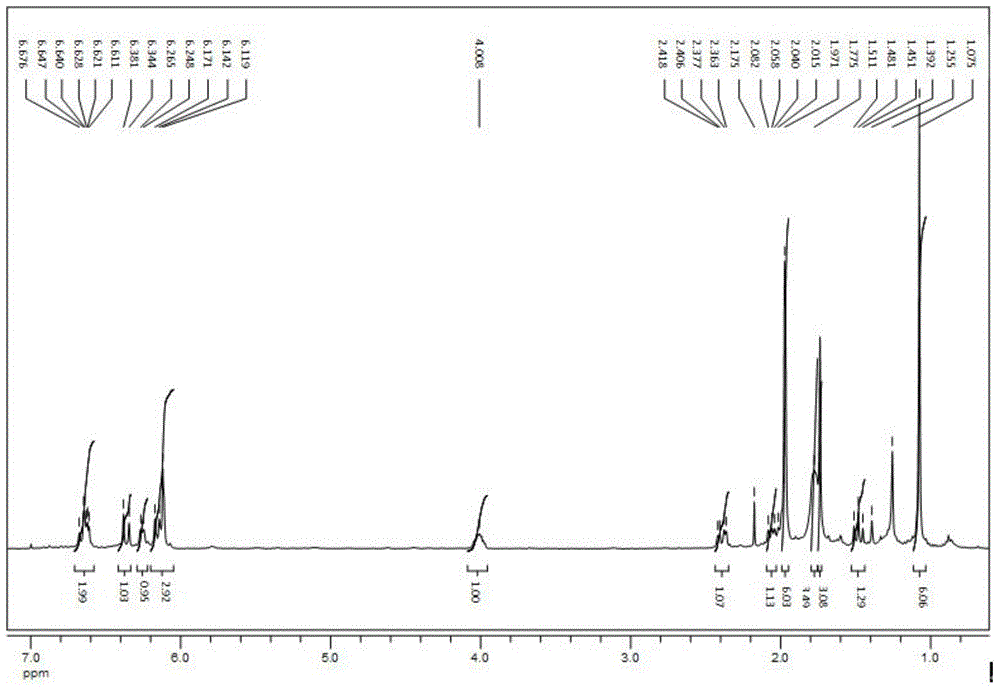

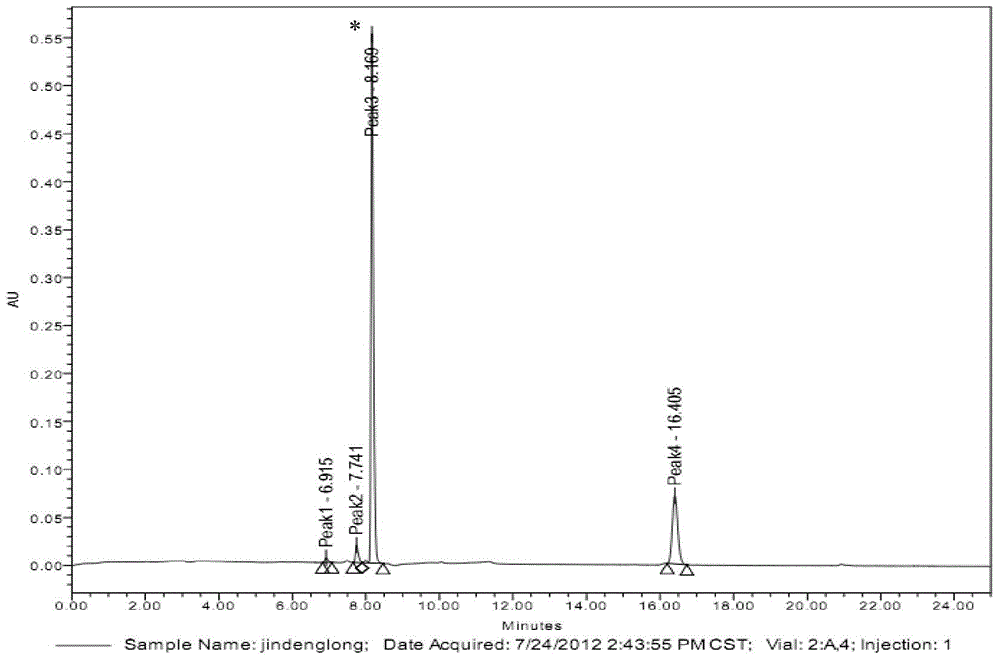

[0054] Using the fruit of Jindenglong as raw material, zeaxanthin was prepared according to the following process:

[0055] Get the brocade lantern fruit freeze-dried, grind into powder, pass through a 100-mesh sieve, take 1000 grams of the powder under the sieve, add 50 liters of acetone according to the ratio of brocade lantern fruit mass:solvent volume=1g:50ml, stir and extract at 60°C for 5 hours, extract After the end, let it stand for precipitation and separation; obtain the extract and filter residue;

[0056] Add 50 liters of acetone to the filter residue again for the second extraction; stir and extract at 60°C for 5 hours; after the extraction, let it stand for precipitation and separation; obtain the extract and filter residue;

[0057] The extraction was repeated 3 times; the combined extracts were concentrated in vacuum until the organic solvent evaporated, and 50 liters of 30% NaOH methanol solution was added, and stirred and saponified at 60°C for 10 hours;

[...

Embodiment 3

[0061] Using capsicum as raw material, prepare zeaxanthin according to the following process:

[0062] Freeze-dry peppers, grind them into powder, pass through a 100-mesh sieve, take 1000 grams of powder under the sieve, add petroleum ether and dichloromethane mixed solvent (volume ratio 1:1) 100 ml according to the ratio of pepper mass:solvent volume=1g:100ml liter, stirred and extracted at 80°C for 1 hour, and left to settle and separate after the extraction; the extract and filter residue were obtained;

[0063] Add 100 liters of mixed solvent of petroleum ether and dichloromethane to the filter residue again for the second extraction; stir and extract at 80°C for 1 hour; after the extraction is completed, let it stand for precipitation and separation; obtain the extract and filter residue;

[0064] The extraction was repeated 3 times; the combined extracts were concentrated in vacuo until the organic solvent evaporated, and 10 liters of 50% KOH ethanol solution was added, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com