Functional fixing plate, production method and use thereof

A positioning board and functional technology, which is applied in the field of shape memory low-temperature thermoplastic functional positioning board, can solve the problem of single function and achieve the effects of improving comfort, promoting wound healing, and improving human immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

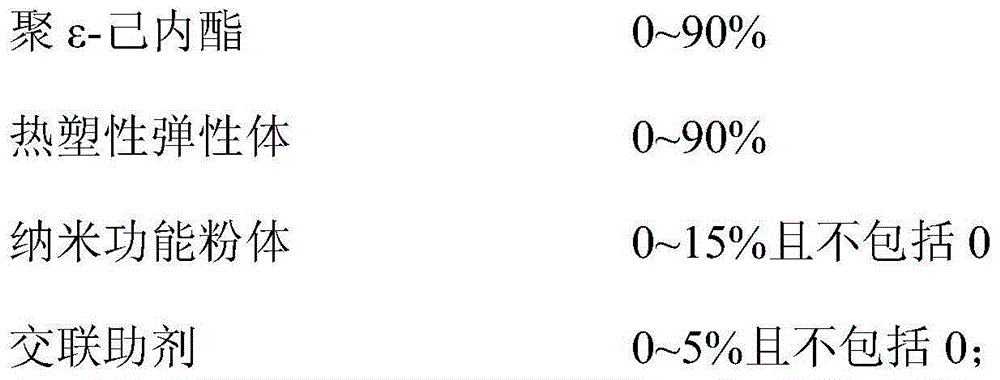

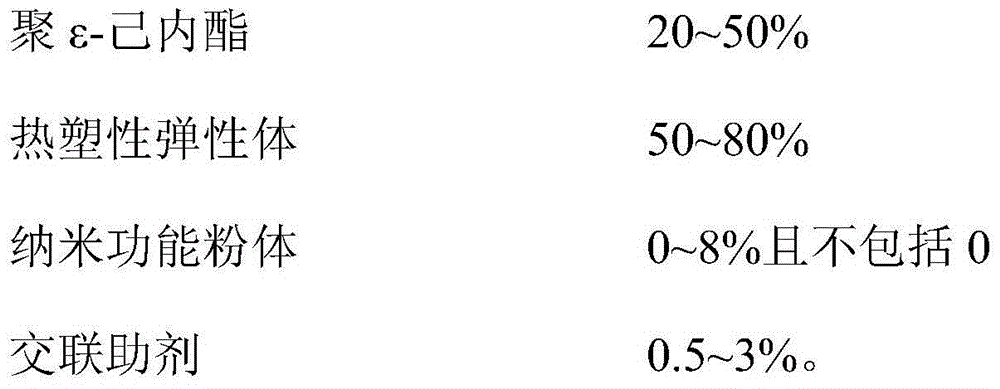

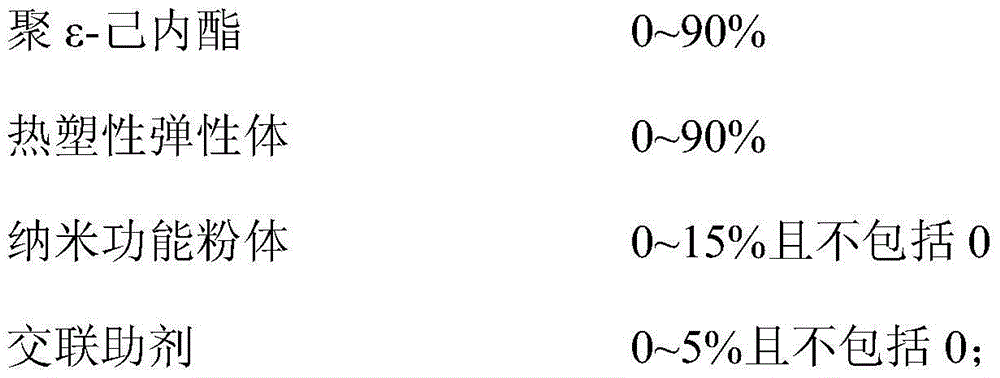

Method used

Image

Examples

Embodiment 1

[0050] After fully dispersing 10 kg of nano-antibacterial powder loaded with Ag ions in a high-speed mixer, spray 200 g of isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate on the In the nanopowder, react at 30° C. for 1 hour.

[0051] Weigh 70kg of polyε-caprolactone, 30kg of thermoplastic polyurethane, 4kg of nano antibacterial powder loaded with Ag ions after modification, 0.5kg of benzoyl peroxide, 0.5kg of triallyl isocyanurate, antioxidant 0.1kg of additive and 0.1kg of light stabilizer, mixed evenly, extruded after melt blending with a twin-screw extruder, and rolled into a plate. Perforate and cut according to requirements to obtain functional positioning boards of different specifications.

Embodiment 2

[0053] 10 kilograms of nano inorganic antibacterial materials loaded with Al ions are fully dispersed in a high-speed mixer, and 200 g of isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate is sprayed on the In the nanopowder, react at 30° C. for 3 hours.

[0054] Weigh 90kg of polyε-caprolactone, 5kg of modified nano-antibacterial powder loaded with Al ions, 2.5kg of dicumyl peroxide, and 2.5kg of diallyl phthalate, and mix them uniformly at 60- Melt and blend with a twin-screw extruder at a temperature of 180°C, then extrude and calender into a plate. Perforate and cut according to requirements to obtain functional positioning boards of different specifications.

Embodiment 3

[0056] After fully dispersing 10 kg of Cu ion-loaded nano-inorganic antibacterial materials in a high-speed mixer, spray 200 g of isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate into the In the nanopowder, react at 80°C for 0.5 hours.

[0057] Weigh 45kg of ethylene-vinyl acetate, 45kg of thermoplastic polyisoprene, 5kg of modified nano-antibacterial powder loaded with Cu ions, 2.5kg of di-tert-butyl peroxide and 2.5kg of trimethylolpropane triacrylate , mixed evenly, melted and blended with a twin-screw extruder at a temperature of 60-180 ° C, extruded, and rolled into a plate. Perforate and cut according to requirements to obtain functional positioning boards of different specifications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com