Metal-chloride melt material with high heat conductivity as well as preparation method and application of metal-chloride melt material

A high thermal conductivity, chloride technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of low application research of chloride molten salt high-temperature heat transfer and heat storage materials, etc., to achieve comprehensive development and utilization, and enhance heat conduction Excellent performance and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A metal-chloride molten salt material, the preparation method is as follows:

[0027] 0.05wt% magnesium powder, 99.95wt% calcium chloride (the tailing waste salt in the salt lake potash fertilizer production process is refined to obtain, and the specific steps are according to "Zhang Shuxia et al. The feasibility of extracting dehydrated calcium chloride by using the old brine of the Hobson salt field Property analysis [J]. Yunnan Chemical Industry, 2008, 35 (4): 17-20 "operation, the material used in the following example is mixed with embodiment 1) and stirred uniformly, statically heated to 850 ℃ to all melting of solid, then heat preservation 8 hours , then naturally cooled to room temperature, and mechanically pulverized to obtain a metal-chloride molten salt material.

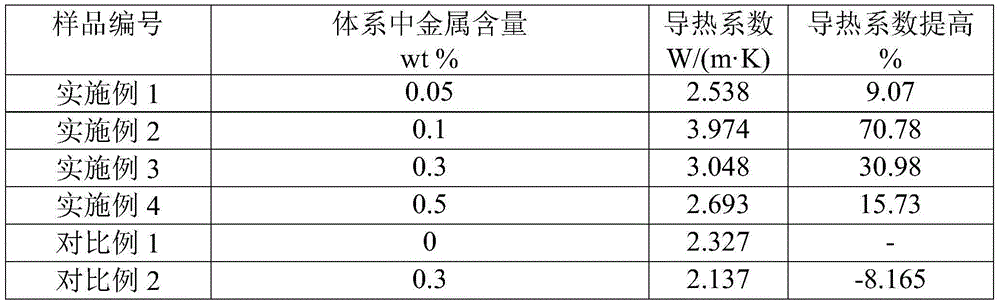

[0028] A differential scanning calorimeter was used to test the melting point of the metal-chloride molten salt material prepared in this example, and the test results are shown in Table 1. A Hotd...

Embodiment 2

[0030] A metal-chloride molten salt material, the preparation method is as follows:

[0031] Mix 0.1wt% magnesium powder and 99.9wt% calcium chloride and stir evenly, statically heat to 850°C until the solids are completely melted, then keep warm for 8 hours, then naturally cool to room temperature, and mechanically pulverize to obtain metal-chloride fusion salt material.

[0032] The test method is the same as in Example 1, and the results are shown in Tables 1-2.

Embodiment 3

[0034]A metal-chloride molten salt material, the preparation method is as follows:

[0035] Mix 0.3wt% magnesium powder and 99.7wt% calcium chloride and stir evenly, statically heat to 850°C until the solids are completely melted, then keep warm for 8 hours, then naturally cool to room temperature, and mechanically pulverize to obtain metal-chloride fusion salt material.

[0036] The test method is the same as in Example 1, and the results are shown in Tables 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com