Method and system for producing lng from waste pyrolysis gas

A technology for pyrolysis of gas and waste, used in gas fuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of dioxin production, improve the hydrogen-carbon ratio, change the pyrolysis process, avoid dioxin and secondary The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

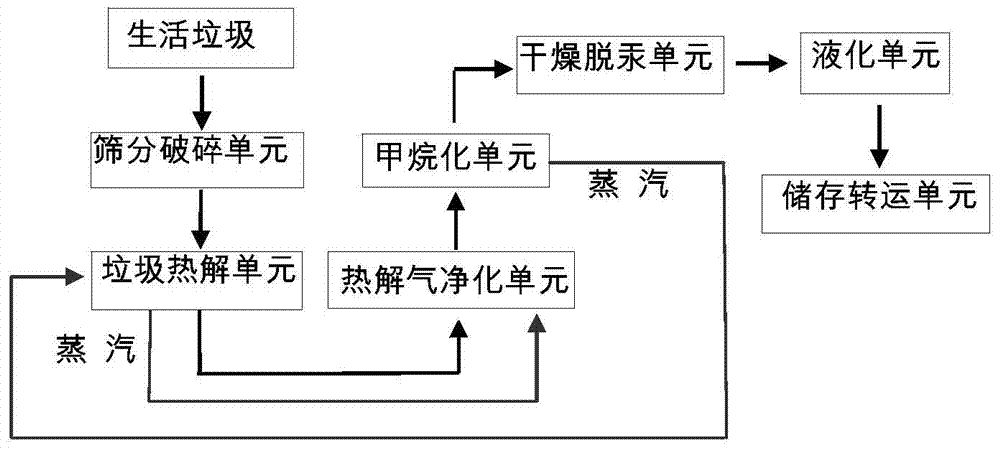

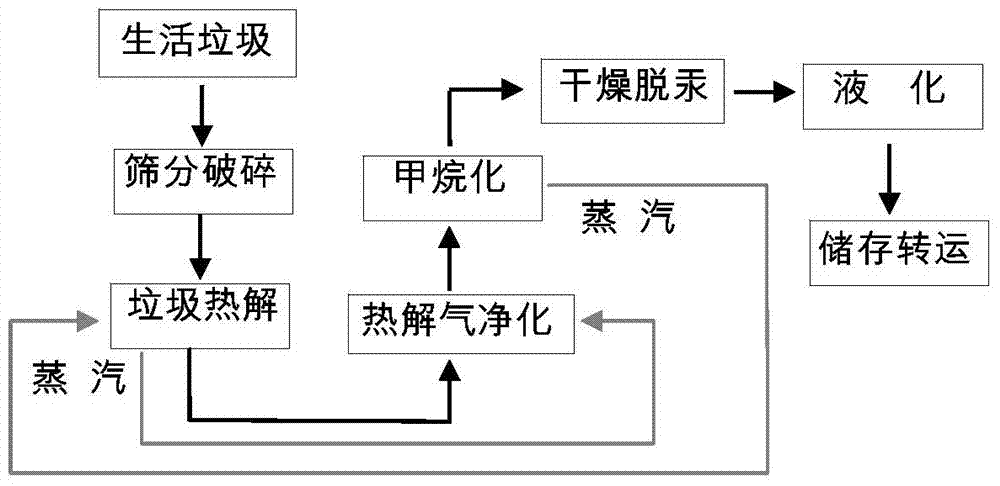

[0047] See figure 1 , figure 2 , the system for producing LNG includes a screening and crushing unit, a garbage pyrolysis unit, a pyrolysis gas purification unit, a methanation unit, a drying unit and a liquefaction unit, and the above units are connected in sequence;

[0048] Wherein, the garbage pyrolysis unit includes a garbage pyrolysis device, the flue gas outlet of the garbage pyrolysis device is connected with a waste heat boiler, and the solid material outlet of the garbage pyrolysis device is connected with a combustion device; the pyrolysis gas purification The unit includes a washing tower, a heavy hydrocarbon removal tower, an absorption tower and a deoxygenation reactor connected in sequence; the drying unit includes drying equipment and mercury removal equipment connected in sequence, and the liquefaction unit includes a low-temperature heat exchanger and a gas-liquid separator connected in sequence , Distillation tower and storage tank. The garbage pyrolysis ...

Embodiment 2

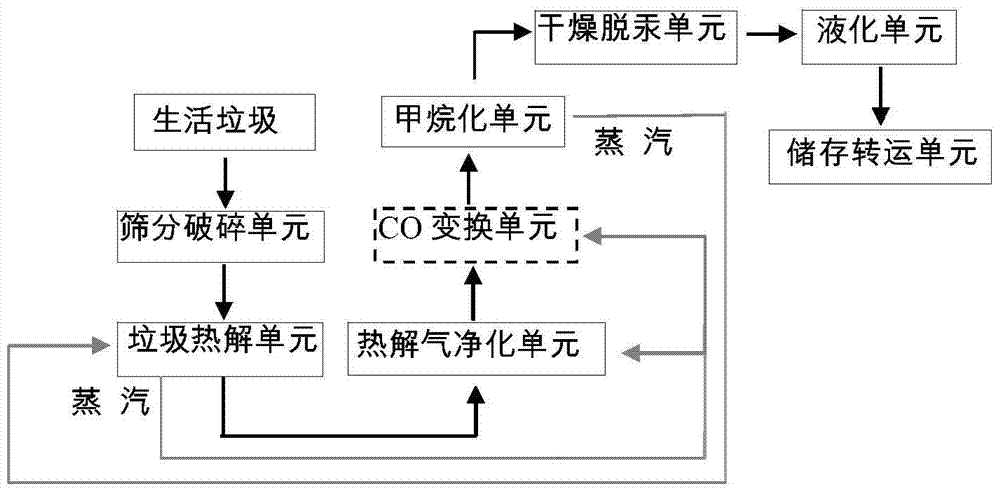

[0060] See image 3 with Figure 4 , compared with the system of Example 1, the system of this embodiment also includes a CO conversion unit, the CO conversion unit is arranged between the pyrolysis gas purification unit and the methanation unit, and the CO conversion unit includes sequentially connected oil-water separation device, mixer, heat exchanger, shift furnace, and water cooler and gas-liquid separator connected through pipelines; wherein, the heat exchanger is a tube heat exchanger, and the gas outlet of the shift furnace is connected to the The heating medium inlet of the heat exchanger, the heating medium outlet of the heat exchanger is connected to the water cooler.

[0061] The production of LNG from waste pyrolysis gas includes the following steps:

[0062] 1. Sieving and crushing: same as embodiment 1 of the present invention.

[0063] 2. Garbage pyrolysis: The municipal solid waste with a particle size of 3-5mm after crushing is sent to the garbage pyrolysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com