Resourceful treatment system adopting straw to produce biogas and having efficient desulphurization and decarbonization functions

A treatment system and biogas production technology, which is applied in the field of straw production biogas resource treatment system, can solve the problems of insufficient gas contact effectively, reduce the concentration of alkaline solution, and reduce the absorption efficiency, so as to realize resource utilization and improve utilization. efficiency, high decarburization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention are further described below in conjunction with specific embodiments.

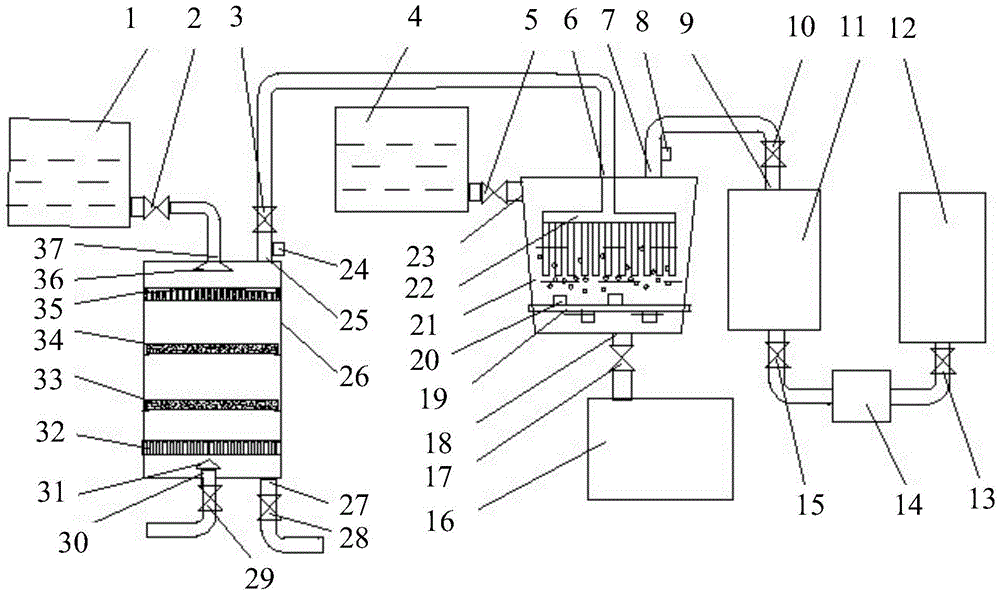

[0026] as attached Figure 7 As shown in the figure, a straw-produced biogas resource treatment system with high-efficiency desulfurization and decarbonization functions includes a straw storage bin a, a rapid degradation tank b, a hydrolysis tank c, an independent heat exchanger d, a CSTR integrated reactor e, and a biogas purification tank. Device f, foliar fertilizer bin g, biogas slurry temporary storage tank h, solid-liquid separator i, organic fertilizer bin j; the straw storage bin is connected to the fast degradation tank; the fast degradation tank is connected to the hydrolysis tank through pipes; The independent heat exchanger is connected; the independent heat exchanger is connected with the CSTR integrated reactor and the solid-liquid separator respectively through the pipeline; the CSTR integrated reactor is connected with the biogas puri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com