Method for recovering waste SCR (Selective Catalytic Reduction) denitration catalyst

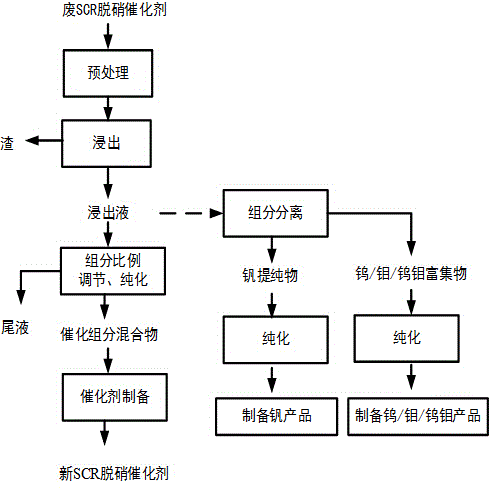

A technology of SCR catalyst and denitration catalyst is applied in the field of recycling and processing waste SCR denitration catalyst, which can solve the problems such as inability to achieve efficient separation and acquisition, inability to realize recycling and remanufacturing of waste SCR denitration catalyst, and lack of mature waste catalyst recycling and processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Waste vanadium molybdenum series SCR denitrification catalyst provided by a laboratory, V 2 o 5 The content is 1.1%, MoO 3 3.3%, TiO 2 95.3%.

[0049] (1) Take 10g of the above spent catalyst, pulverize it to 100 mesh, wash it with water, filter it, and dry it at 105°C. NaOH is added to the dried spent catalyst as an additive, and the molar ratio of NaOH to the total amount of metal in the spent catalyst is m add :m metal =1. After mixing evenly, put it in a muffle furnace for roasting, the roasting temperature is 650°C, and the roasting time is 4h;

[0050] (2) Using neutral pure water as the leaching agent, leaching V and Mo from the spent catalyst after roasting in step (1), the liquid-solid ratio is 0.02L / g, the leaching temperature is 20°C, and the leaching pressure is 0.1MPa. The time is 1.5h, the stirring speed is 1000r / min, the V single-stage leaching rate is 78.6%, Mo is 75.7%; the leaching residue returns to step (1);

[0051] (3) The extraction system...

Embodiment 2

[0056] Waste vanadium molybdenum series SCR denitrification catalyst provided by a laboratory, V 2 o 5 The content is 1.4%, MoO 3 3.2%, TiO 2 95%.

[0057] (1) Take 5g of the above spent catalyst, pulverize it to 100 mesh, wash it with water, filter it, and dry it at 105°C. NaOH is added to the dried spent catalyst as an additive, and the molar ratio of NaOH to the total amount of metal in the spent catalyst is m add :m metal =2. After mixing evenly, place it in a muffle furnace for roasting, the roasting temperature is 680°C, and the roasting time is 5h;

[0058] (2) Using neutral pure water as the leaching agent, leaching V and Mo from the spent catalyst after roasting in step (1), the liquid-solid ratio is 0.06L / g, the leaching temperature is 60°C, and the leaching pressure is 0.1MPa. The time is 2 hours, the stirring speed is 800r / min, the V single-stage leaching rate is 79.6%, Mo is 77.4%; the leaching residue returns to step (1);

[0059] (3) The extraction syste...

Embodiment 3

[0064] The waste vanadium tungsten based SCR denitrification catalyst provided by a laboratory, V 2 o 5 The content is 1.5%, WO 3 3.3%, TiO 2 95%.

[0065] (1) Take 10g of the above spent catalyst, pulverize it to 100 mesh, wash it with water, filter it, and dry it at 105°C. Add Na to the dried spent catalyst 2 CO 3 As an additive, Na 2 CO 3 The molar ratio m to the total amount of metal in the spent catalyst add :m metal =6. After mixing evenly, place it in a muffle furnace for roasting, the roasting temperature is 500°C, and the roasting time is 7 hours;

[0066] (2) Use neutral pure water as the leaching agent, leaching V and W from the spent catalyst after roasting in step (1), the liquid-solid ratio is 0.05L / g, the leaching temperature is 70°C, and the leaching pressure is 0.1MPa. The time is 1.5h, the stirring speed is 1200r / min, the V single-stage leaching rate is 79.6%, and the W is 76.4%; the leaching residue returns to step (1);

[0067] (3) The extractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com