Test method for bonding strength of chopped ultrafine organic fiber and cement-based composite interface

A technology of organic fiber and interface bonding, which is applied in the direction of analysis materials, preparation of test samples, and measurement devices, can solve problems such as difficult operation, inability to freely adjust the verticality of the main axis of the fiber, and large dispersion of test results, so as to avoid The effects of damage, accurate test results, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Example of testing the interface bond strength between polyvinyl alcohol fiber and cement-based composite material.

[0040] The raw materials include polyvinyl alcohol fibers (12 mm in length and 39 μm in diameter), ordinary Portland cement, water, sample-carrying cuboid, hollow cuboid mold, double-sided adhesive, and quick-drying adhesive.

[0041] The sample preparation process is as follows:

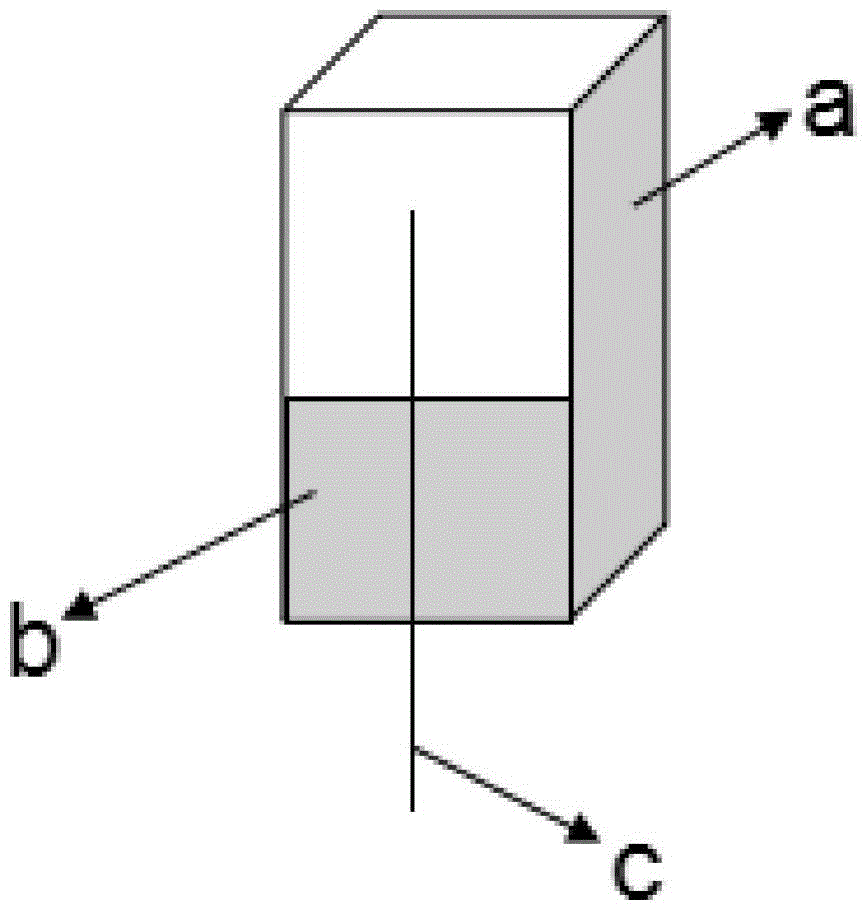

[0042] 1. Paste the polyvinyl alcohol fiber on the 10mm×5mm×2mm sample loading cuboid with double-sided tape, and the fiber length exposed at the lower end is 1.5mm.

[0043] 2. Prepare a cuboid mold for forming the cement matrix. The mold size is 30mm×10mm×5mm. Pour the evenly stirred cement-based material (ordinary Portland cement and water in a mass ratio of 3:1) into the mold, and vibrate until the surface Smooth out to obtain a cement matrix.

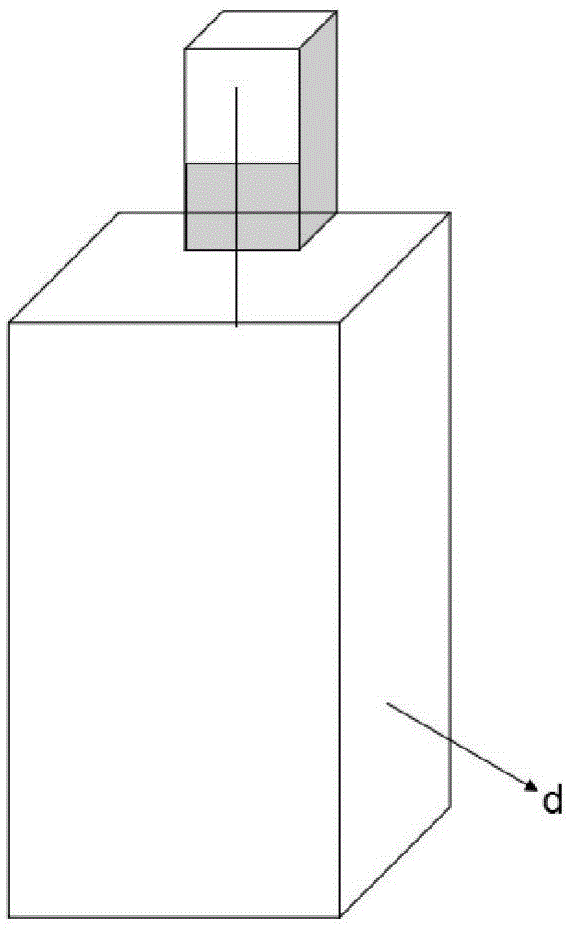

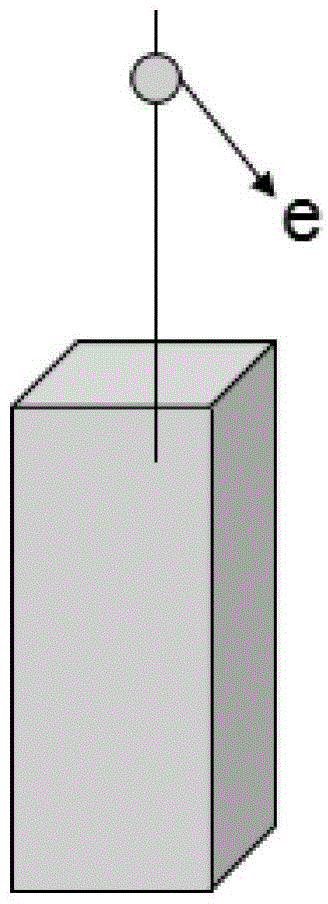

[0044] 3. Insert the exposed end of the fiber pasted on the sample-loading cuboid in step 1 vertically into the ceme...

Embodiment 2

[0049] Example 2: Example of testing the interface bond strength between cellulose fiber and cement-based composite material.

[0050] Raw materials include cellulose fibers (3 mm in length and 15 μm in diameter), ordinary Portland cement, water, fiber-loaded cuboid, hollow cuboid mold, double-sided adhesive, and quick-drying adhesive.

[0051] The sample preparation process is as follows:

[0052] 1. Use double-sided tape to paste the cellulose fiber on the 10mm×5mm×2mm sample loading cuboid, and the fiber length exposed at the lower end is 1.0mm.

[0053] 2. Prepare a cuboid mold for forming the cement matrix. The mold size is 30mm×10mm×5mm. Pour the evenly stirred cement-based material (ordinary Portland cement and water in a mass ratio of 3:1) into the mold, and vibrate until the surface Smooth out to obtain a cement matrix.

[0054] 3. Insert the exposed end of the fiber pasted on the sample-loading cuboid in step 1 vertically into the cement matrix in step 2, and place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com