Ceramic wall floor tile production line monitoring system

A monitoring system and production line technology, applied in general control system, control/adjustment system, program control, etc., can solve problems such as inability to reflect production information and equipment status to management personnel, waste, loss, etc., and achieve timely and effective adjustment of production planning , improve work efficiency, reduce the effect of inaccurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

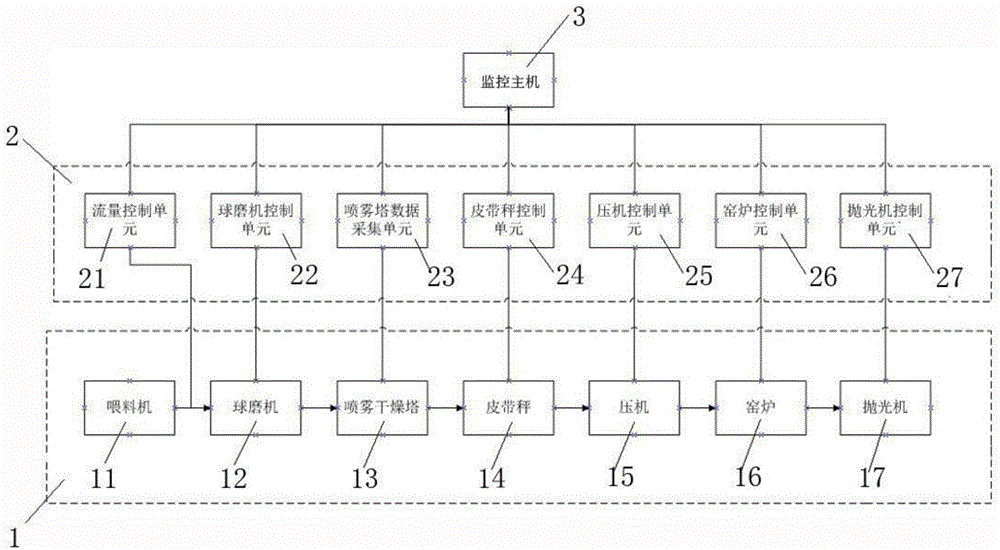

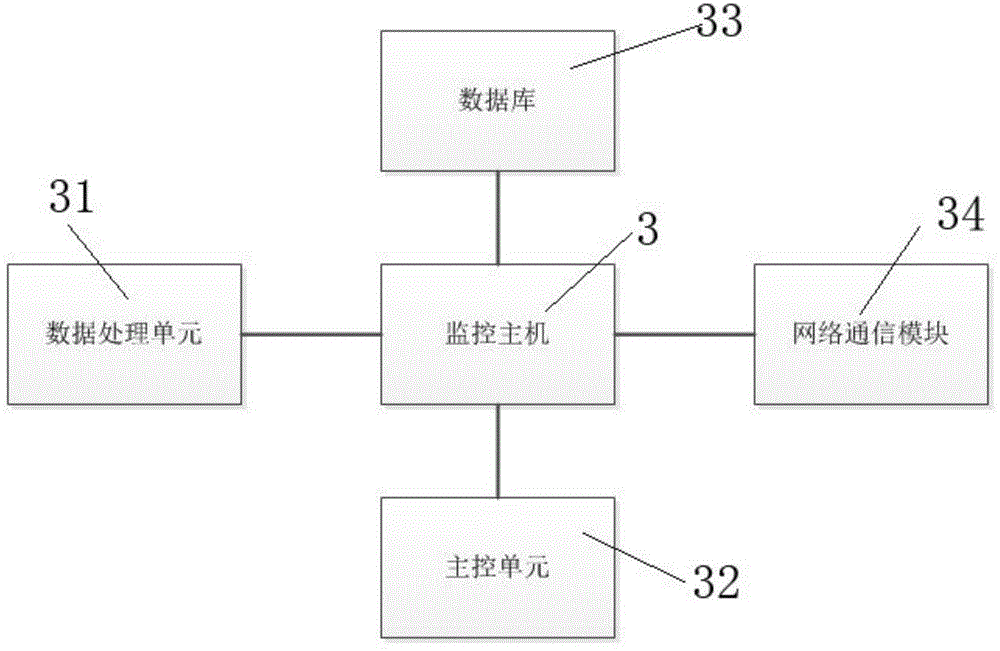

[0023] A ceramic wall and floor tile production line monitoring system of the present invention includes a production line 1, a communication control device 2, a monitoring host 3 and a switch.

[0024] The production line 1 includes a feeder 11, a ball mill 12, a spray drying tower 13, a belt scale 14, a press 15, a kiln 16 and a polishing machine 17, and each equipment of the production line 1 is provided with an alarm. The process flow of the production line 1 is as follows: the ball mill 12 mixes the raw materials sent by the feeder 11 with water to make a slurry, and sends it to the spray drying tower 13 . The spray drying tower 13 dries the incoming slurry water to make powder. The belt scale 14 sends the powder into the press 15 after batching according to the amount. The press 15 presses the raw material into shape, and sends it into the kiln 16 for rapid sintering. The polishing machine 17 polishes the sintered wall and floor tiles. Finally, the packages are sorted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com