Light-emitting diode epitaxial slice and preparation method thereof

A technology of light-emitting diodes and epitaxial wafers, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult to meet the content requirements, difficult to meet a higher requirement, weak In-N bond strength, etc., and achieve high formation probability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

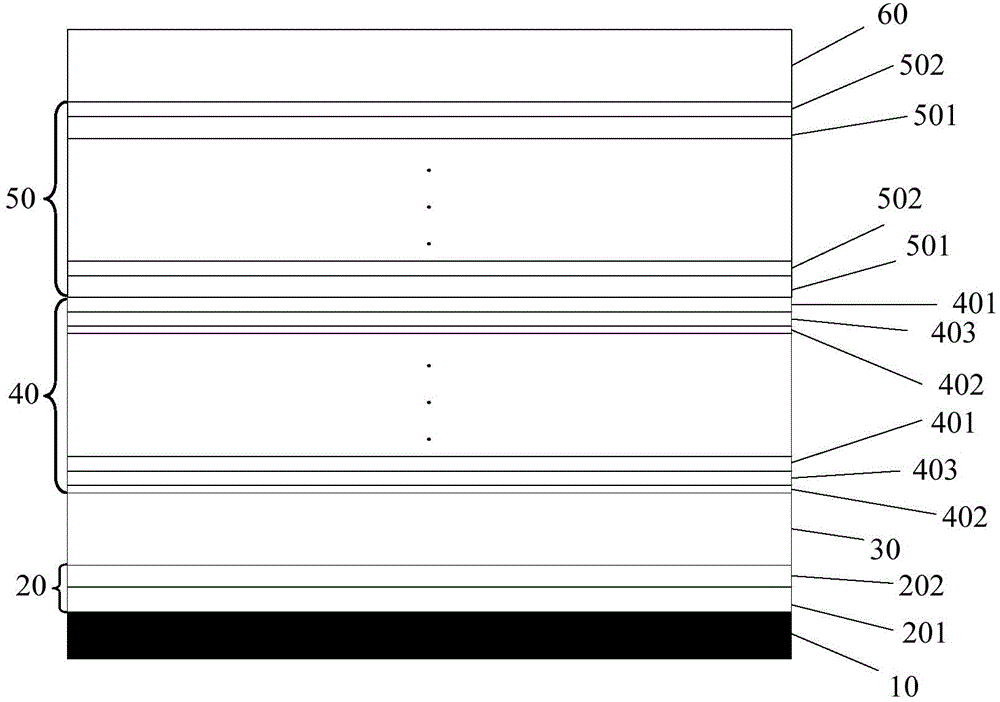

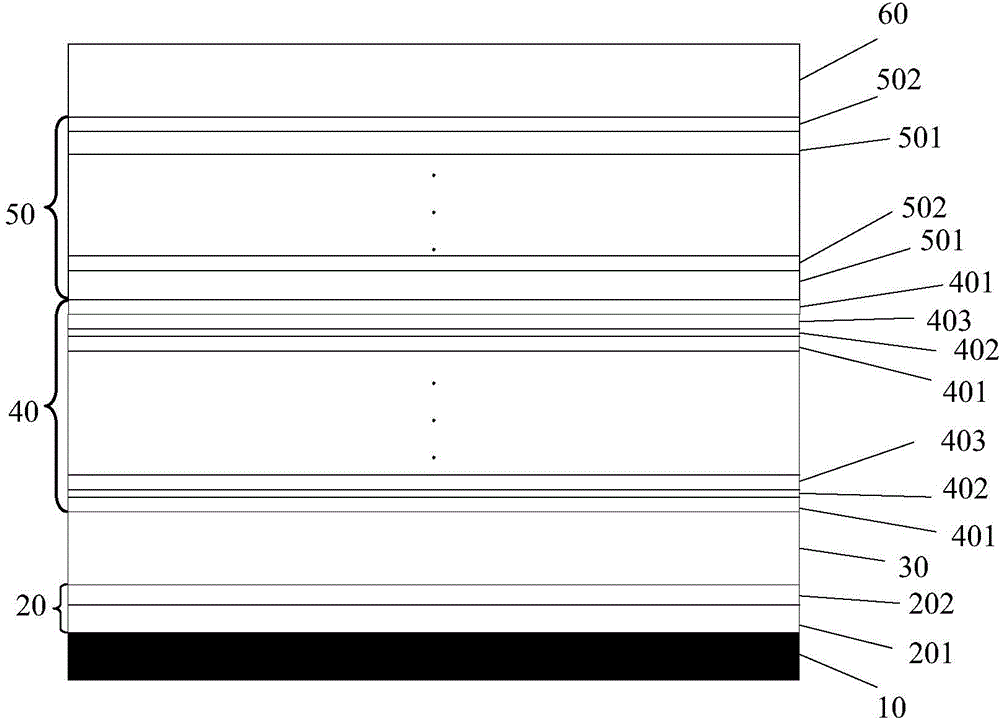

[0027] An embodiment of the present invention provides an epitaxial wafer of a light emitting diode, see figure 1 and figure 2 , the epitaxial wafer comprises a substrate 10, a buffer layer 20 grown on the substrate, an N-type layer 30, a stress release layer 40, a multi-quantum well layer 50 and a P-type layer 60, and the multi-quantum well layer 50 is a superlattice structure , each period of the MQW layer can include In y Ga 1-y N layer 501 and grown on In y Ga 1-y The GaN layer 502 on the N layer 501, 0x Ga 1-x N layer 403, 0<x<y.

[0028] In this embodiment, the number of periods of the stress release layer 40 may be 2-20.

[0029] In the first implementation, see figure 1 , each period of the stress release layer 40 may include an InN layer 402, In grown on the InN layer 402 x Ga 1-x N layer 403 and grown on In x Ga 1-x The GaN layer 401 above the N layer 403 , that is, starting from the side of the N-type layer 30 , and the first InN layer 402 in the stress ...

Embodiment 2

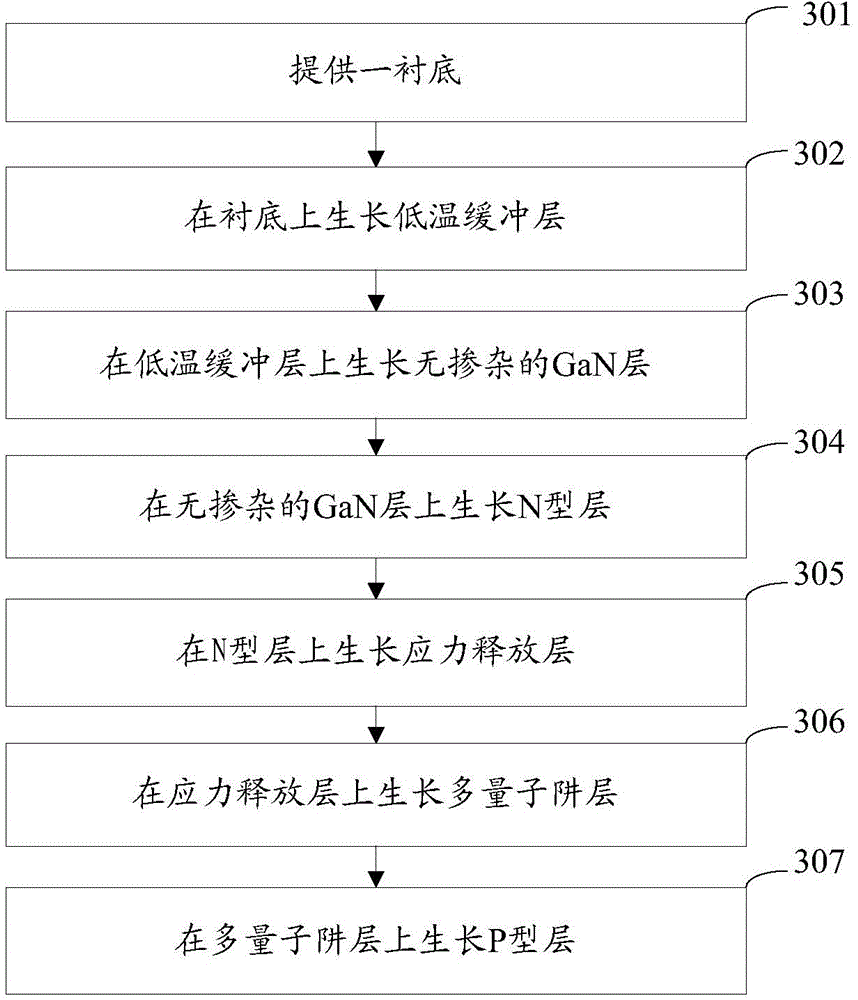

[0045] An embodiment of the present invention provides a method for preparing an epitaxial wafer of a light emitting diode, see image 3 , the method includes:

[0046] Step 301: Provide a substrate.

[0047] Specifically, the substrate may be a sapphire substrate, and may also be a Si substrate or a SiC substrate.

[0048] This step may also include cleaning the surface of the substrate. When it is realized, the sapphire substrate can be heated to 1110°C in a MOCVD (Metal-organic Chemical Vapor Deposition) reaction chamber, under hydrogen (H 2 ) atmosphere to anneal the sapphire substrate for 8 to 10 minutes to clean the surface of the substrate.

[0049] Step 302: growing a low-temperature buffer layer on the substrate.

[0050] Specifically, at a temperature of 540° C., a GaN layer with a thickness of about 30 nm is grown on the substrate as a low-temperature buffer layer.

[0051] Step 303: growing an undoped GaN layer on the low-temperature buffer layer.

[0052] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com