Composite anti-microbial air filtration material, preparation method and application

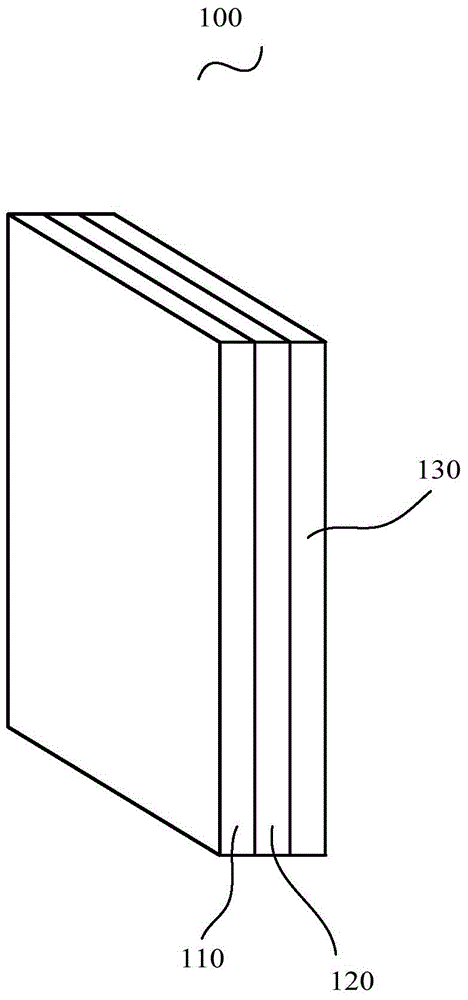

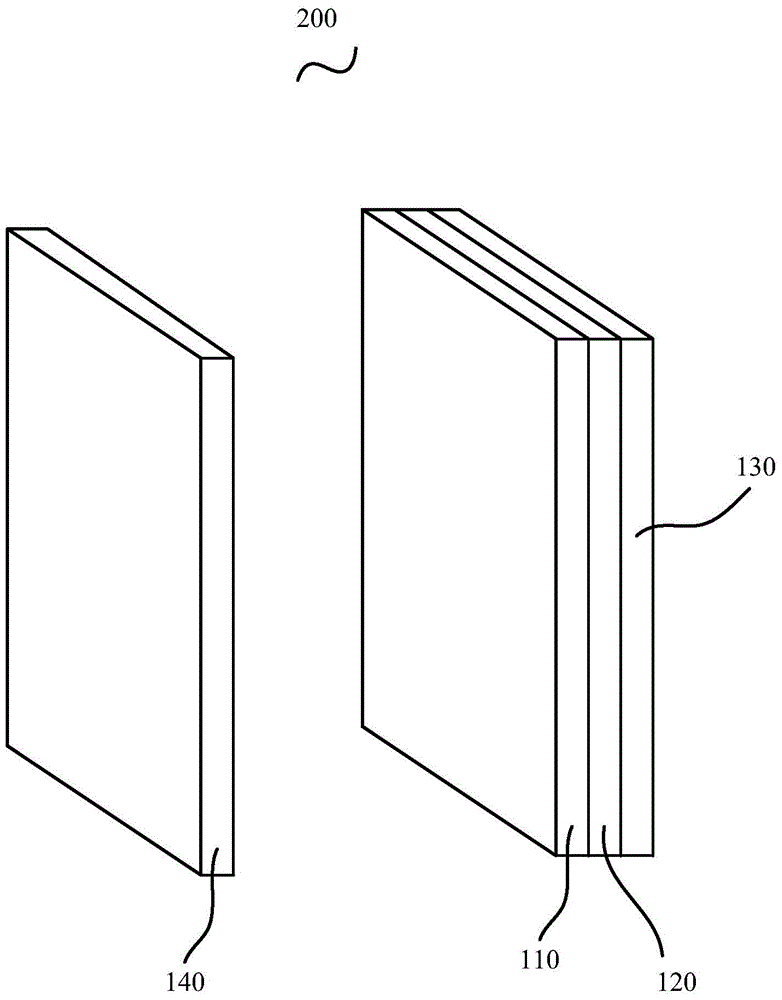

An air filter material and composite antibacterial technology, applied in the field of air filter materials, can solve the problems of difficult industrialization of electrospinning, difficulty in forming large-scale products, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

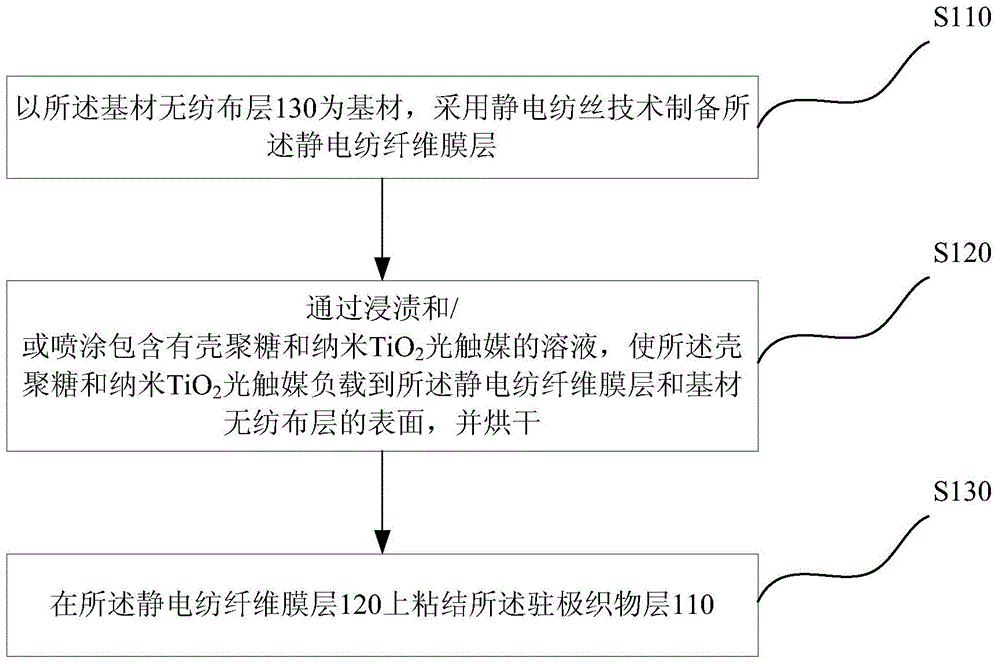

Method used

Image

Examples

Embodiment 1

[0052] The polypropylene pellets were added to the melt electrospinning equipment for electrospinning, and the nylon woven cloth with a mesh number of 250 was used as the receiving substrate, and the thickness of the electrospun film was 10 μm.

[0053] Dissolve chitosan in 10% acetic acid solution, the concentration is 5%, spray on the upper and lower surfaces of the composite electrospun membrane, the amount is 20ml / m2; the nano TiO 2 The photocatalyst is dispersed in water with a concentration of 0.05%, and is sprayed on the upper and lower surfaces of the composite electrospun membrane in an amount of 25ml / m2.

[0054] 15g / m 2 The melt-blown polypropylene electret non-woven fabric is covered on the surface of the electrospun membrane.

[0055] The 150-mesh nylon weave is arranged in front of the electret non-woven fabric as a curtain to prevent haze.

[0056] The filtration test adopts the GB2626-2006 test standard, the equipment adopts the TSI8130 filter material tester...

Embodiment 2

[0058] Dissolve polyacrylonitrile in N,N-dimethylacetamide at a concentration of 6%, and spin it with a solution electrospinning machine, and the receiving substrate is 30g / m 2 Polypropylene melt-blown non-woven fabric with an electrospun film thickness of 3 μm.

[0059] Dissolve chitosan in 3% acetic acid solution, the concentration is 3%, spray on the upper and lower surfaces of the composite electrospun membrane, the amount is 10ml / m 2 ; Nano-TiO 2 The photocatalyst is dispersed in water, the concentration is 0.02%, sprayed on the upper and lower surfaces of the composite electrospun membrane, the amount is 15ml / m 2 .

[0060] 25g / m 2 The melt-blown polypropylene electret non-woven fabric is covered on the surface of the electrospun membrane.

[0061] The filtration test adopts the GB2626-2006 test standard, the equipment adopts the TSI8130 filter material tester, the aerosol used in the test is NaCl, the mass median particle size is 0.26 μm, and the number median parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com