Device and method for removing VOCs (volatile organic chemicals) by low-temperature plasma and electrostatic spinning-photocatalysis technology

A low-temperature plasma and electrospinning technology, which is applied in the field of devices for removing VOCs by ion synergistic electrospinning-photocatalysis technology, can solve the problems of easy poisoning and deactivation of catalysts, unstable ultraviolet light source, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

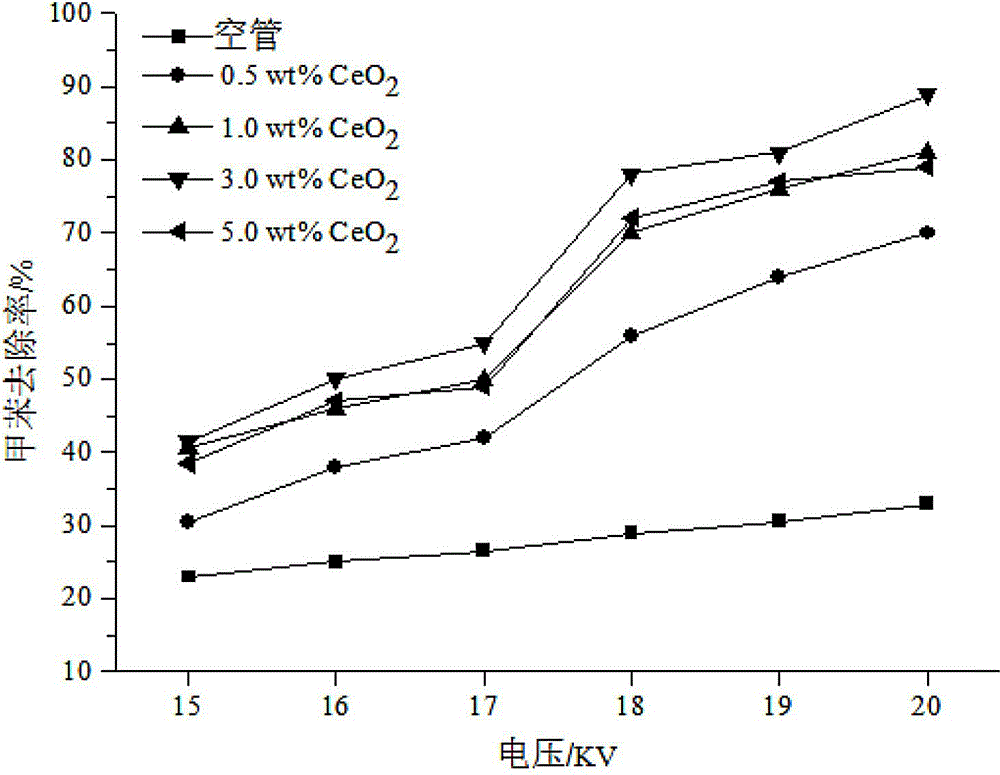

Embodiment 1

[0031] According to the above CeO 2 / TiO 2 The preparation method of nanofiber photocatalytic material, in the Erlenmeyer flask with stopper of 20ml, add the butyl titanate of 5ml (Ti(OC 4 h 9 ) 4), then slowly add acetic acid dropwise, the volume ratio of butyl titanate and acetic acid is 1.3, and magnetically stir for 30min, the solution is yellow and transparent, which is used as the precursor solution. Then configure a 1.0mol / L polystyrene solution, the solvent is a mixed solvent of tetrahydrofuran (THF) and N,N-dimethylformamide (DMF) (DMF / THF=4 / 6 (wt)), and then add the above Precursor solution and cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) and 0.01437g, 0.02889g, 0.08843g and 0.1505g of cerium nitrate, respectively, and uniformly stirred for 3 hours under magnetic force until the solution was bright, light yellow, transparent and clear, and used as the spinning solution.

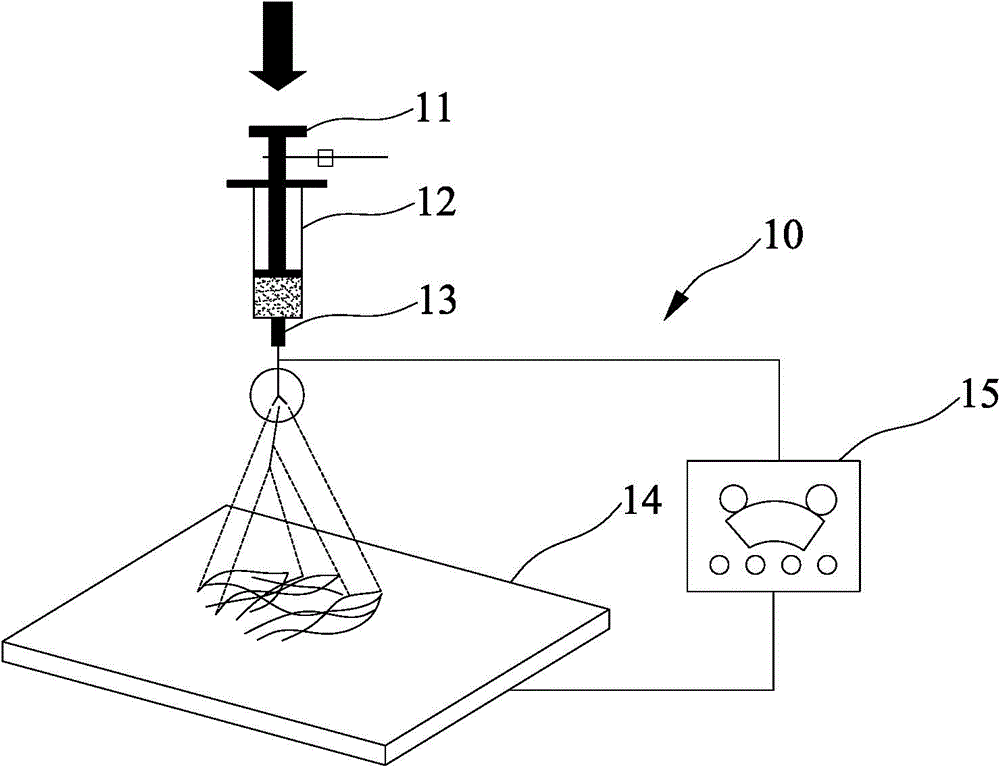

[0032] Inhale the spinning solution into a 5ml glass syringe with a stainless steel needle, conne...

Embodiment 2

[0036] According to the above CeO 2 / TiO 2 The preparation method of nanofiber photocatalytic material, in the 20ml Erlenmeyer flask with stopper, add 5ml of butyl titanate (Ti(OC 4 h 9 ) 4 ), then slowly add acetic acid dropwise, the volume ratio of butyl titanate and acetic acid is 1.3, and magnetically stir for 30min, the solution is yellow and transparent, which is used as the precursor solution. Then configure a polystyrene solution with a certain concentration, the solvent is a mixed solvent of tetrahydrofuran (THF) and N,N-dimethylformamide (DMF) (DMF / THF=4 / 6 (wt)), and then add the above precursor solution and cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), 0.08843g of cerium nitrate, stirred evenly by magnetic force for 3h, until the solution was bright light yellow, transparent and clear, and used as spinning solution.

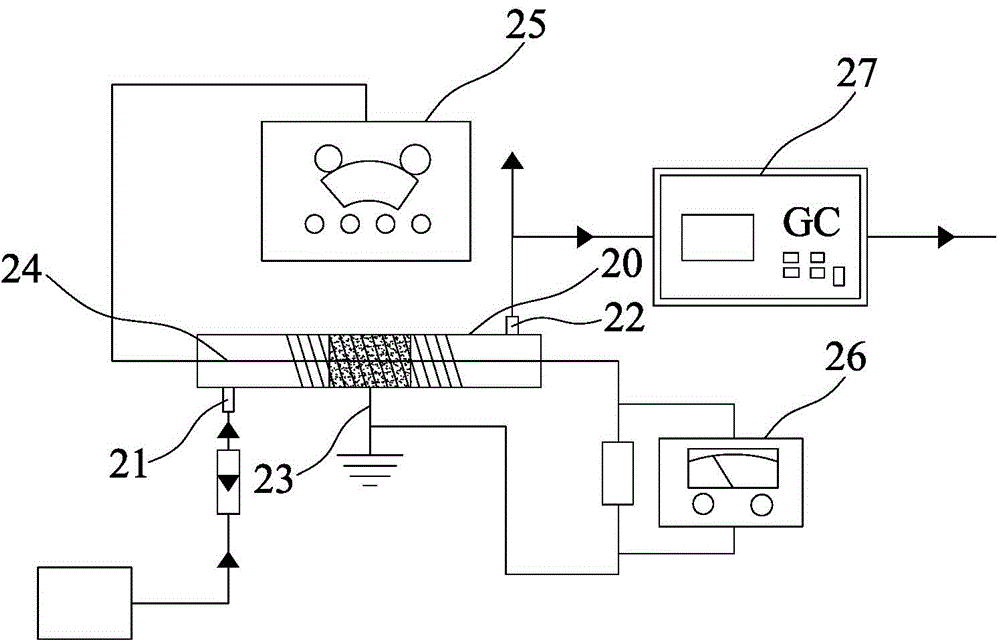

[0037] Inhale the spinning solution into a 5ml glass syringe with a stainless steel needle, connect the needle tip to the positive pole of the power su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com