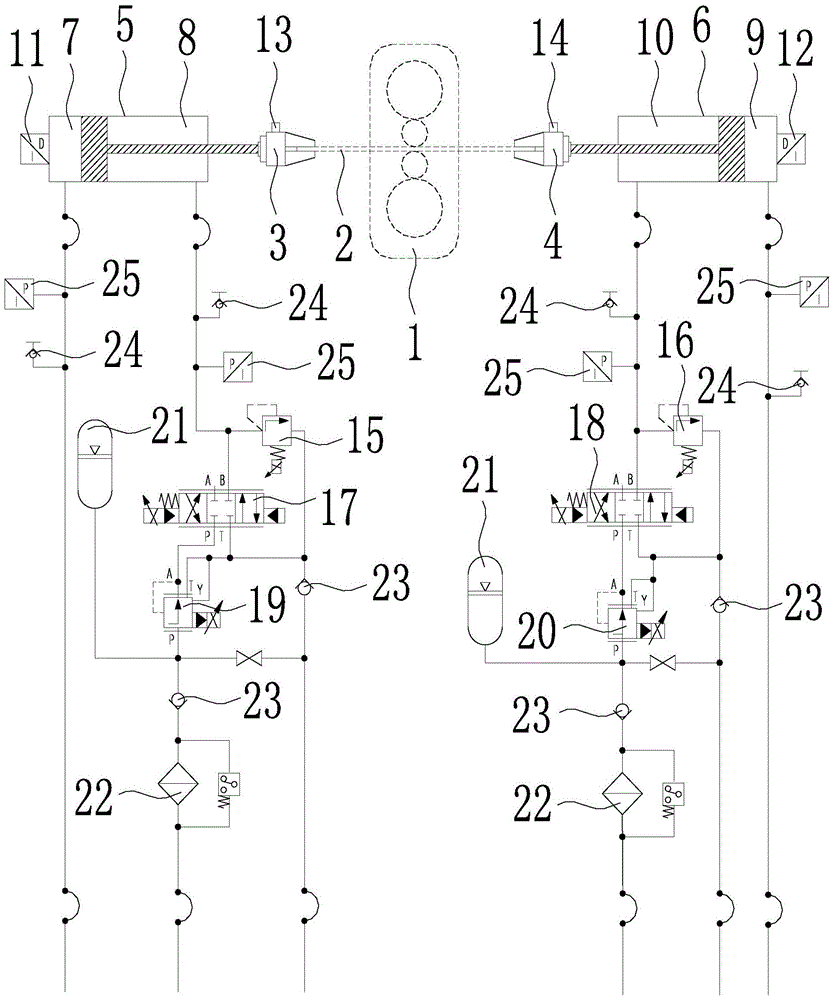

A micro-tension control system and method for a hydraulic tension warm rolling mill

A technology of micro-tension control and hydraulic system, applied in the direction of tension/pressure control, etc., can solve the problems of large calculation errors of forward slip rate and rear slip rate, low precision of tension control, broken strip, etc., and improve the final rolling quality , The tension control method is simple and effective, and the effect of ensuring the precision of tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] In this embodiment, the rolled piece 2 is an AZ31 magnesium alloy strip, the initial size is 3.95mm×200mm×1000mm, and the target thickness size is 0.7mm; the size of the backup roll of the hydraulic tension warm rolling mill is φ480×350mm, and the size of the work roll is φ200× 370mm; the cylinder diameter of the left and right tension hydraulic cylinders is 90mm, the diameter of the piston rod is 63mm, and the stroke is 2100mm; the flow rate of the left and right proportional pressure reducing valves is 40L / min; the model of the left and right servo valves is D661; The flow rate of the right proportional relief valve is 40L / min; the maximum range of the left and right displacement sensors is 2150mm, and the measurement accuracy is 0.01mm; the maximum range of the left and right tensiometers is 10kN, and the measurement accuracy is 0.1kN; The high pressure oil provided by the high pressure oil source of the system is 21MPa, and the low pressure oil provided by the low pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com