Continuous sand filtration-ozone catalytic oxidation combined wastewater treatment equipment and application method thereof

A technology for ozone catalytic oxidation and wastewater treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult to meet, improve effluent water quality, singleness, etc., to achieve Reduce volume and floor space, reduce operating costs, and feature obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

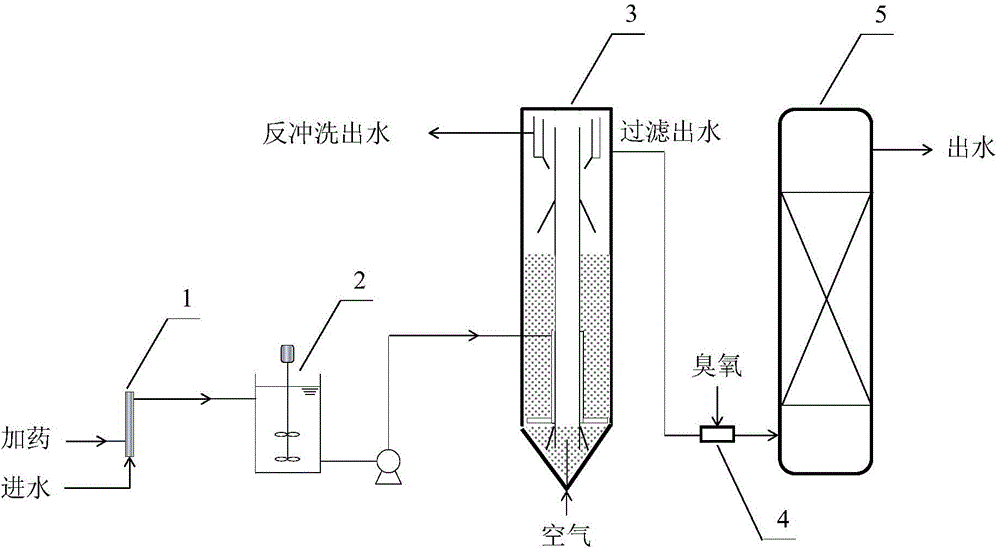

[0028] A continuous sand filter-ozone catalytic oxidation combined wastewater treatment device, comprising a pipeline mixing unit 1, a microflocculation reaction unit 2, a continuous sand filter unit 3, an ejector ozone mixing unit 4 and an ozone catalytic oxidation unit 5 connected in sequence through pipelines; The micro-flocculation reaction unit 2 is filled with a coagulant, the continuous sand filter unit 3 is filled with sand filter packing, and the ozone catalytic oxidation unit 5 is filled with a catalyst.

[0029] The above schemes can already complete the advanced treatment of wastewater, and the optimal scheme is given below on this basis:

[0030] The coagulant is PAC; the sand filter filler is quartz sand; the catalyst is loaded Al 2 o 3The solid catalyst filler has a filling ratio of 30% to 50%; the diameter of the quartz sand is 0.5 to 1.0mm.

Embodiment 2

[0032] A wastewater treatment method, comprising the following steps: the wastewater enters the pipeline mixing unit 1 and is fully mixed and then enters the micro-flocculation reaction unit 2 for micro-flocculation reaction, and then injects air and micro-flocculated wastewater into the The continuous sand filtration unit 3 performs continuous sand filtration, and the wastewater after the continuous sand filtration is fully mixed with ozone through the jet ozone mixing unit 4 and then injected into the ozone catalytic oxidation unit 5 for ozone catalytic oxidation.

[0033] The above schemes can already complete the advanced treatment of wastewater, and the optimal scheme is given below on this basis:

[0034] The micro-flocculation reaction adopts mechanical stirring, and the G value is 50-100s -1 , the flocculation hydraulic retention time is 2~7min; the filtration rate of the continuous sand filter is maintained at 6~10m / h, and the gas-water ratio is 8:1~10:1; the hydrauli...

Embodiment 3

[0036] A continuous sand filtration-ozone catalytic oxidation combined wastewater treatment method, the method is carried out using a continuous sand filtration-ozone catalytic oxidation combined device, and the device is as follows figure 1 As shown, it includes a pipeline mixing unit 1 , a microflocculation reaction unit 2 , a continuous sand filter unit 3 , an ejector ozone mixing unit 4 and an ozone catalytic oxidation unit 5 connected in sequence. The wastewater to be treated is the biochemical secondary effluent of industrial wastewater. The method includes the following steps: the industrial wastewater is first mixed with PAC and then enters the pipeline mixing unit. The waste water enters the reaction pool, the reaction pool is equipped with mechanical stirring, and the G value is 50s -1 Around, the residence time is 2-7 minutes, the effluent from the reaction tank enters the continuous sand filter, the filtration rate is maintained at 6-10m / h, the gas-water ratio is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com