Rotary double-needle electrospinning device and method for preparing uniform nanofiber membrane

A nanofiber membrane, electrospinning technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of not collecting fibers, uneven fiber membrane, and difficult to completely cover the fiber membrane, etc. Achieve the effect of simple equipment, improved thickness uniformity, and increased area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

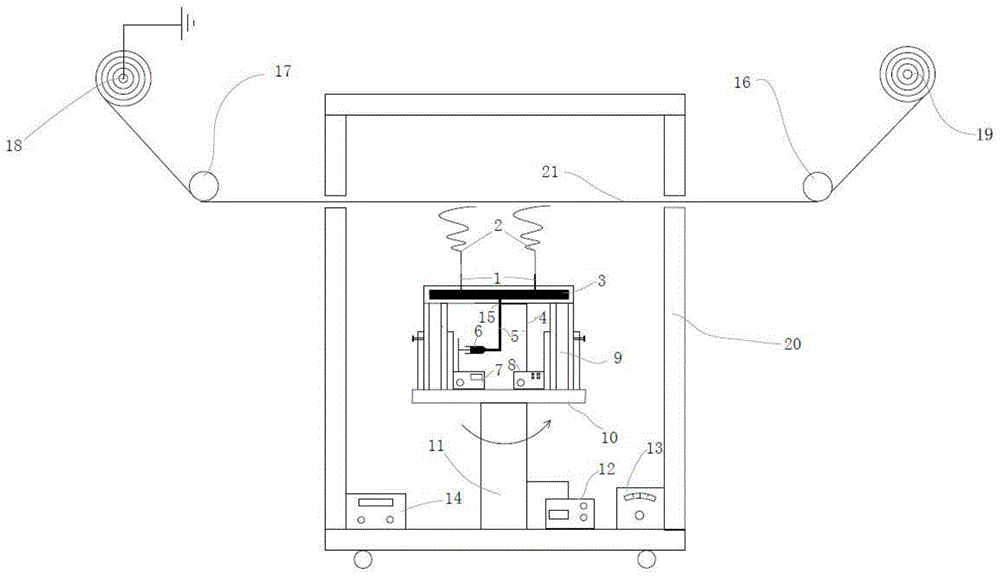

[0051] Polyacrylonitrile (PAN) was dissolved in a solvent N,N-dimethylformamide (DMF) to prepare a spinning solution with a concentration of 13 wt%. The spinning liquid is injected into the syringe 6, and the temperature inside the spinning chamber 20 is 25°C and the relative humidity is 40% by controlling the temperature regulator 13 and the humidity regulator 14. Turn on the micro-injection pump, set the flow rate to 0.3mL / h, turn on the DC high-voltage generator 8, and control the voltage to 20kV, the electrospinning jet is deposited on the collection curtain 21 in a spiral trajectory, and the drive motor 12 is turned on to drive the rotary platform 10 to rotate, Turn on the shutter roller and rotate forward and reverse 10 times to obtain a nanofibrous membrane with uniform thickness. The CV value of the square meter gram weight of the nanofiber membrane is 9.25%.

Embodiment 2

[0053] Polyvinyl alcohol (PVA) 1788 powder was dissolved in 70° C. distilled water to prepare a spinning solution with a concentration of 16 wt%. The spinning solution is injected into the syringe 6, and the temperature inside the spinning chamber 20 is 25°C and the relative humidity is 60% by controlling the temperature regulator 13 and the humidity regulator 14. Turn on the micro-injection pump, set the flow rate to 0.5mL / h, turn on the DC high-voltage generator 8, and control the voltage to 40kV, the electrospinning jet is deposited on the collection curtain 21 in a spiral trajectory, and the drive motor 12 is turned on to drive the rotating platform 10 to rotate, Turn on the shutter roller and rotate forward and reverse 10 times to obtain a nanofibrous membrane with uniform thickness. The CV value of the square meter gram weight of the nanofiber membrane is 8.78%.

Embodiment 3

[0055] Polyethylene oxide (PEO) was dissolved in 60° C. distilled water to prepare a spinning solution with a concentration of 14 wt%. The spinning solution is injected into the syringe 6, and the temperature inside the spinning chamber 20 is 25°C and the relative humidity is 50% by controlling the temperature regulator 13 and the humidity regulator 14. Turn on the micro-injection pump, set the flow rate to 0.4mL / h, turn on the DC high-voltage generator 8, and control the voltage to 30kV, the electrospinning jet is deposited on the collection curtain 21 in a spiral trajectory, and the drive motor 12 is turned on to drive the rotary platform 10 to rotate, Turn on the shutter roller and rotate forward and reverse 10 times to obtain a nanofibrous membrane with uniform thickness. The CV value of the square meter gram weight of the nanofiber membrane is 7.65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com