Removing method for gas recovery well shaft aquo-complex blockage

A technology of hydrates and hydrate inhibitors, applied in wellbore/well components, drilling compositions, chemical instruments and methods, etc., can solve the problems of slow unblocking speed, large heat loss, large amount of hot water sources and storage Space and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

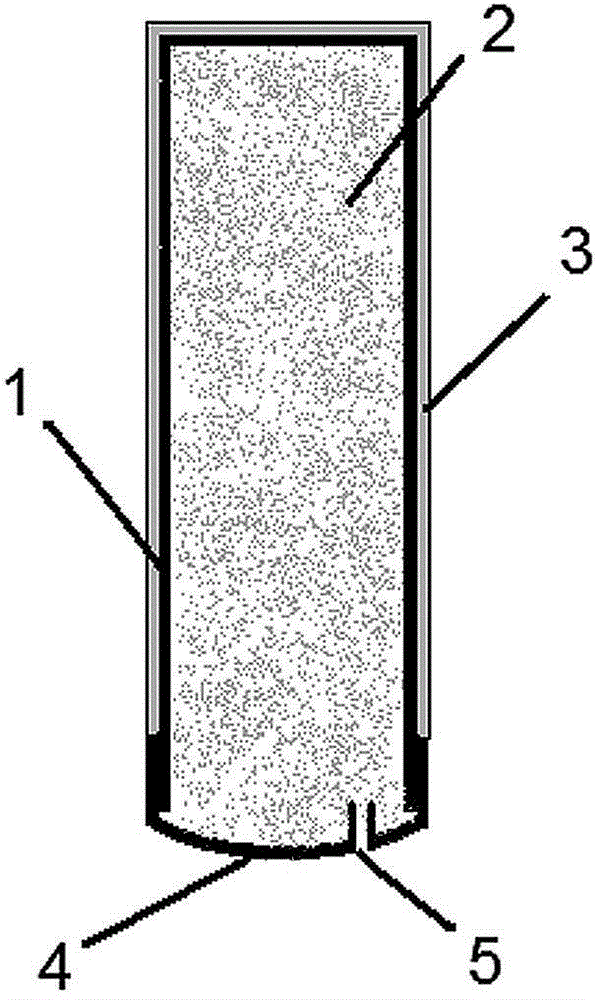

[0025] After natural gas shallow wells (3 Working fluid, its composition ratio by mass fraction is 5% hydrochloric acid; 0.5% corrosion inhibitor; 30% hydrate inhibitor; the rest is water. Then put in a heating unit with an outer diameter less than 10mm of the inner diameter of the wellbore of the gas well through the wax-removing gate of the gas tree, and its length is 500mm. Shut down the well and wait for the reaction. When the wellbore pressure rises and recovers, it can be judged that the wellbore hydrate blockage has been successfully removed.

Embodiment 2

[0027] After deep and shallow wells (3200-4000m) and ultra-deep wells (>4000m) are blocked by hydrate ice, inject 0.3-0.4m through the oil pressure gate of the gas tree. 3 Working liquid, its composition ratio by mass fraction is hydrochloric acid 5%; corrosion inhibitor 1%; hydrate inhibitor 30%; the remaining components are water. Then put in a heating unit with an outer diameter less than 10mm of the inner diameter of the wellbore of the gas well through the wax-removing gate of the gas tree, and its length is 500mm. Shut down the well and wait for the reaction. When the wellbore pressure rises and recovers, it can be judged that the wellbore hydrate blockage has been successfully removed. If the pressure does not recover and rise, it can be judged that the hydrate blockage has not been completely removed, and a new heating unit will be put into the gas tree wax removal gate again. Boil the well behind the body and wait for the hydrate blockage to be removed.

Embodiment 3

[0029] After hydrate ice plugging occurs in a medium gas well containing hydrogen sulfide, inject 0.3~0.4m through the hydraulic gate of the gas tree. 3 The composition of the working fluid is 10% hydrochloric acid by mass fraction; 1%~1.5% corrosion inhibitor; 40%~50% hydrate inhibitor; the rest is water. Then put in a heating unit with an outer diameter less than 10mm of the inner diameter of the wellbore of the gas well through the wax-removing gate of the gas tree, and its length is 500mm. Shut down the well and wait for the reaction. When the wellbore pressure rises and recovers, it can be judged that the wellbore hydrate blockage has been successfully removed. If the pressure does not recover and rise, it can be judged that the hydrate blockage has not been completely removed, and a new heating unit will be put into the gas tree wax removal gate again. Boil the well behind the body and wait for the hydrate blockage to be removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com