Process for manufacturing single-layer multi-point capacitive touch screen with pure ITO membrane structure

A capacitive touch screen, single-layer multi-point technology, applied in electrical digital data processing, data processing input/output process, instruments, etc., can solve the problems of increasing etching process, waste materials, thick product thickness, etc., to reduce etching process, avoid side erosion problems, and facilitate the effect of bridging technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

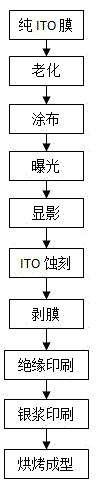

[0029] A kind of pure ITO film structure single-layer multi-point capacitive touch screen manufacturing process provided by the present invention, please refer to figure 1 As shown, the following steps are sequentially included: after cutting the ITO film of a predetermined size, the following steps are carried out in sequence;

[0030] S1. Aging: Carry out high-temperature aging on pure ITO film. The aging temperature is 140°C. Utilizing high-temperature aging can improve the stability of the ITO film substrate, increase the transmittance of the ITO film, and eliminate part of the optical polarization phenomenon at the same time, reducing light. Optical interference between the film layers; secondly, the resistance of the ITO film surface can be changed; thirdly, the ITO can be changed from an amorphous state to a crystalline state to improve stability;

[0031] S2. Coating: apply a liquid photoresist on the surface of the aged ITO film in step S1, the liquid photoresist is t...

Embodiment 2

[0040] A kind of pure ITO film structure single-layer multi-point capacitive touch screen manufacturing process provided by the present invention, please refer to figure 1 As shown, the following steps are sequentially included: after cutting the ITO film of a predetermined size, the following steps are carried out in sequence;

[0041] S1. Aging: Carry out high-temperature aging on pure ITO film. The aging temperature is 140°C. Utilizing high-temperature aging can improve the stability of the ITO film substrate, increase the transmittance of the ITO film, and eliminate part of the optical polarization phenomenon at the same time, reducing light. Optical interference between the film layers; secondly, the resistance of the ITO film surface can be changed; thirdly, the ITO can be changed from an amorphous state to a crystalline state to improve stability;

[0042] S2. Coating: apply a liquid photoresist on the surface of the aged ITO film in step S1, the liquid photoresist is t...

Embodiment 3

[0051] A kind of pure ITO film structure single-layer multi-point capacitive touch screen manufacturing process provided by the present invention, please refer to figure 1 As shown, the following steps are sequentially included: after cutting the ITO film of a predetermined size, the following steps are carried out in sequence;

[0052] S1. Aging: Carry out high-temperature aging on pure ITO film. The aging temperature is 140°C. Utilizing high-temperature aging can improve the stability of the ITO film substrate, increase the transmittance of the ITO film, and eliminate part of the optical polarization phenomenon at the same time, reducing light. Optical interference between the film layers; secondly, the resistance of the ITO film surface can be changed; thirdly, the ITO can be changed from an amorphous state to a crystalline state to improve stability;

[0053] S2. Coating: apply a liquid photoresist on the surface of the aged ITO film in step S1, the liquid photoresist is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com