LED packaging technical process based on iron substrate

A technology of LED packaging and process flow, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of rising LED packaging costs and high copper prices, and achieve the effects of increasing revenue, saving material costs, and reducing capital consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

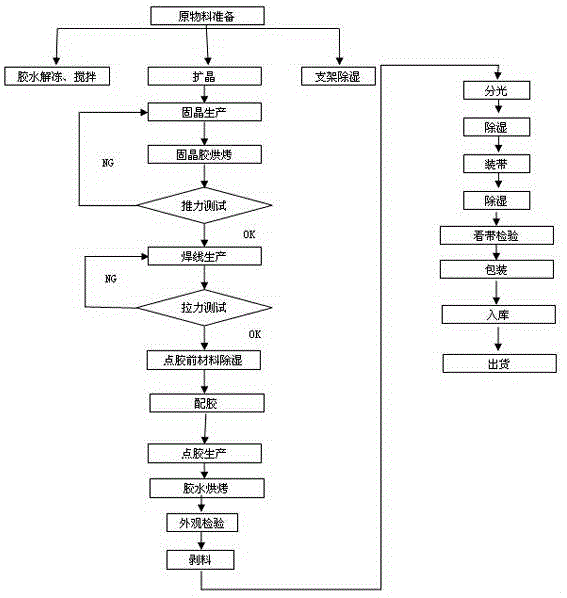

[0032] like figure 1 As shown, a kind of LED encapsulation technological process based on iron substrate of the present invention comprises the following steps:

[0033] a. Ultrasonic cleaning is used to clean the LED bracket. The LED bracket uses iron as the basic material, and the surface is nickel-plated and then silver-plated;

[0034] b. Dry and dehumidify the LED bracket, the dehumidification temperature is 150°C, and the dehumidification time is 2 hours;

[0035] c. Check the chip, whether there is mechanical damage and pitting on the surface of the material, whether the chip size and electrode size meet the process requirements, and whether the electrode pattern is complete;

[0036] d. Carry out the crystal expansion operation on the chip, and use the expansion machine to expand the film bonding the chip, so that the distance between the LED chips is stretched to about 0.6mm;

[0037] e. Thaw and stir the glue. Use syringe-type silver glue and insulating glue. The a...

Embodiment 2

[0056] In step i, the bonding power is 70mw; the bonding pressure is 60gms; the bonding time is 20ms; the bonding temperature is 130°C, and other steps are the same as in the first embodiment.

Embodiment 3

[0058] In step i, the bonding power is 110mw; the bonding pressure is 90gms; the bonding time is 10ms; the bonding temperature is 150°C, and other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com