Multilayer printed circuit board and manufacturing method thereof

A technology of multi-layer printing and manufacturing methods, applied in the directions of printed circuit manufacturing, multi-layer circuit manufacturing, printed circuit, etc., which can solve problems such as distortion and inability to completely solve multi-layer printed wiring boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

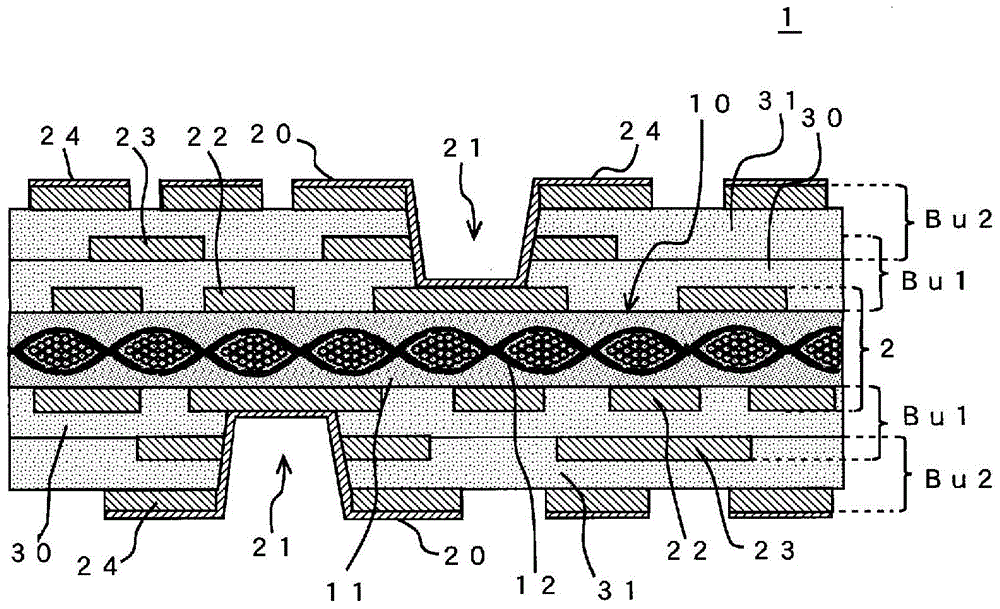

[0089] In this embodiment 1, through the following steps, manufactured such as Figure 6 Shown is a 10-layer multilayer printed wiring board.

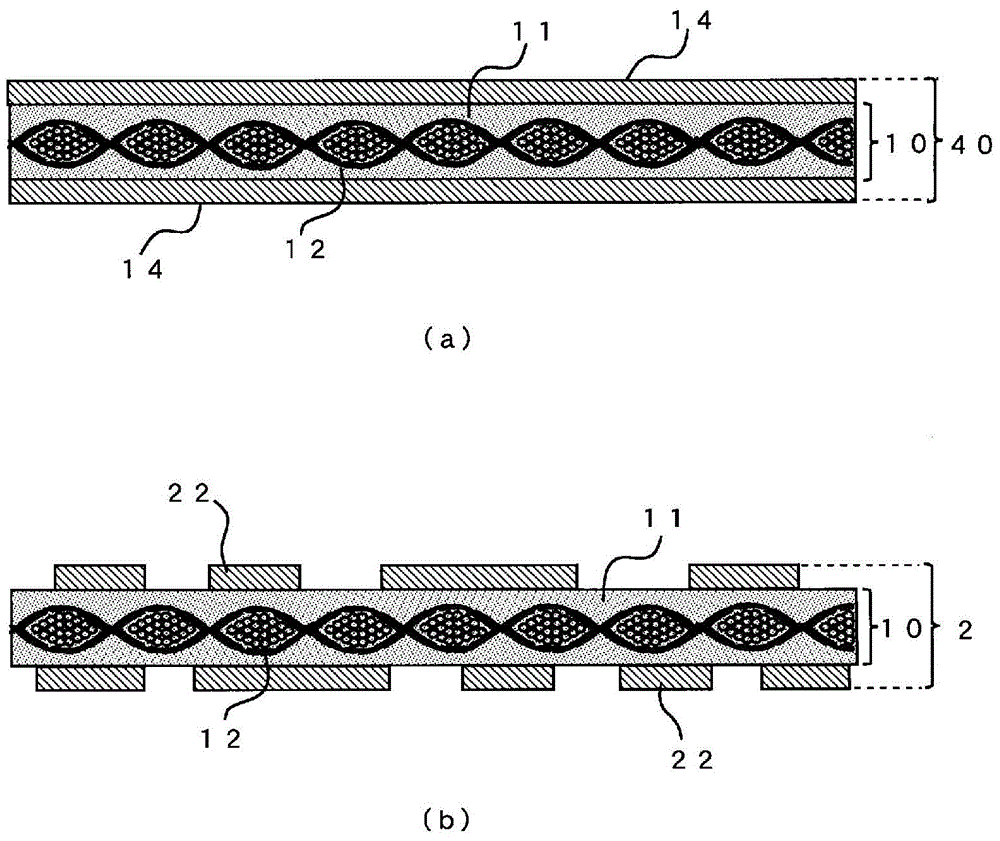

[0090] Step 1: In Example 1, prepared figure 2 (a) Copper-clad laminate with copper foil on both sides of the insulating layer in the state shown (copper foil thickness: 18 μm, insulating layer thickness: 60 μm, insulating layer: containing glass cloth, X-direction linear expansion rate: 14.0ppm / ℃, Y direction linear expansion rate 12.0ppm / ℃). Subsequently, the copper foil of the outer layer of the copper-clad laminate is etched to form predetermined inner-layer circuits 22 on both sides, thereby obtaining the following figure 2 The core substrate 2 in which the thickness of the insulating layer shown in (b) is 150 μm or less.

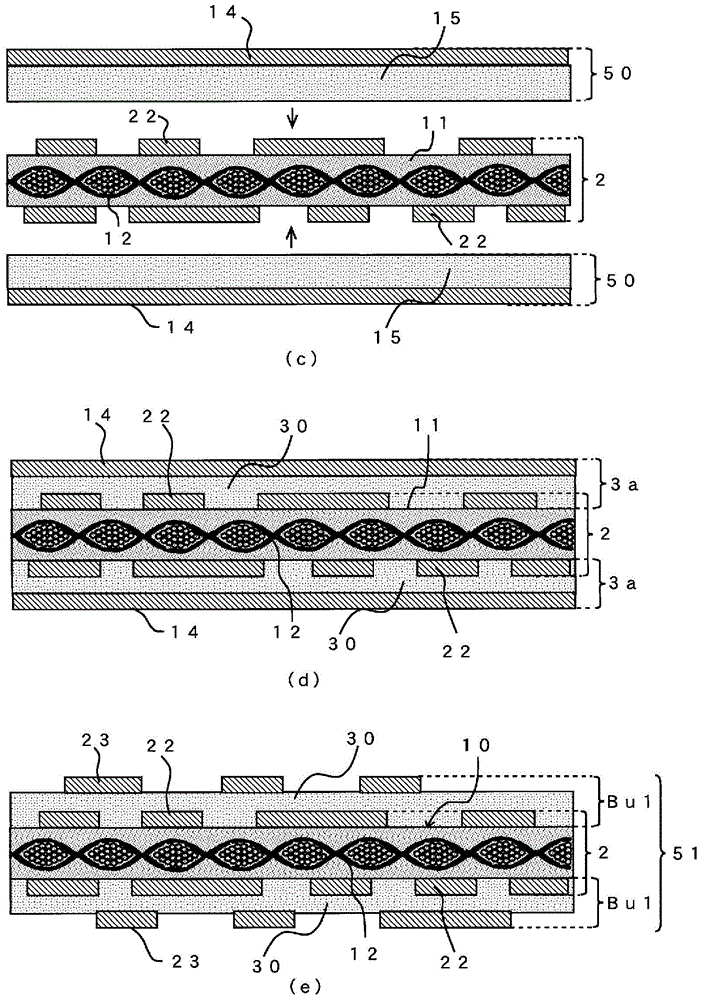

[0091] Process 2: In this process 2, if image 3 As shown in (c), the semi-cured resin layer 15 side of the copper foil 50 (thickness: 30 μm, copper foil thickness: 18 μm, semi-cured resin layer: resin f...

Embodiment 2

[0097] In this Example 2, through the same steps 1 to 4 as in Example 1, the following Figure 6 After the 10-layer multilayer printed wiring board shown, the warpage amount was measured in the same manner as in Example 1. Therefore, only the different parts will be described.

[0098] In this embodiment 2, just use the copper foil 50 (thickness: 30 μ m, copper foil thickness: 18 μ m, semi-cured resin layer: use epoxy resin, cyanate resin and bismaleyl resin) with semi-cured resin layer Resin film made of imide resin), for the insulating resin layer 32 of the first built-up wiring layer Bu1 to the third built-up wiring layer Bu3 formed through the same steps 1 to 3 as in Example 1, linear expansion in the X-Y direction The rate is 24ppm / °C, the ratio of the value of the X-direction linear expansion coefficient (Bx) to the Y-direction linear expansion coefficient (By) of the insulating resin layer is [Bx] / [By]=1.0, and the tensile strength at 25°C is The elastic modulus is 8....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com