A tobacco leaf shredded method for improving the sensory quality of tobacco

A tobacco leaf and quality technology, applied in the direction of tobacco, tobacco preparation, application, etc., to achieve the effects of reducing loss, promoting effective absorption, and controlling length distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

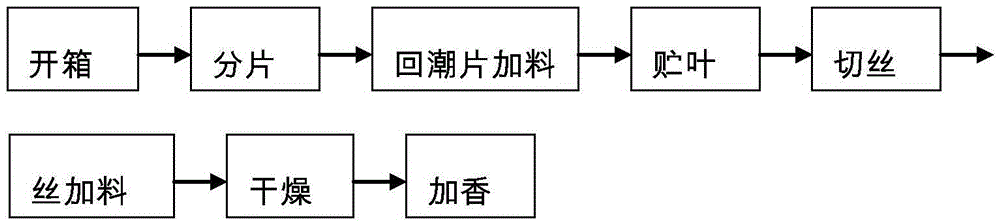

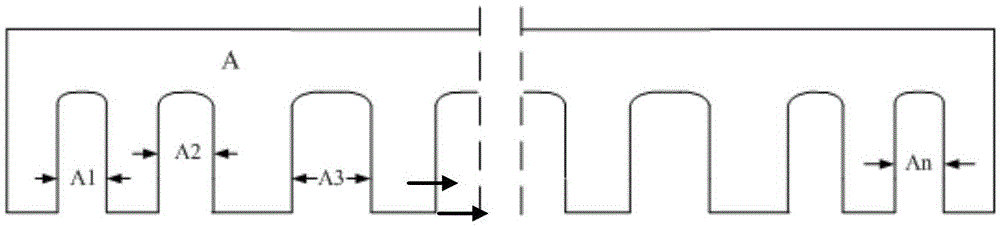

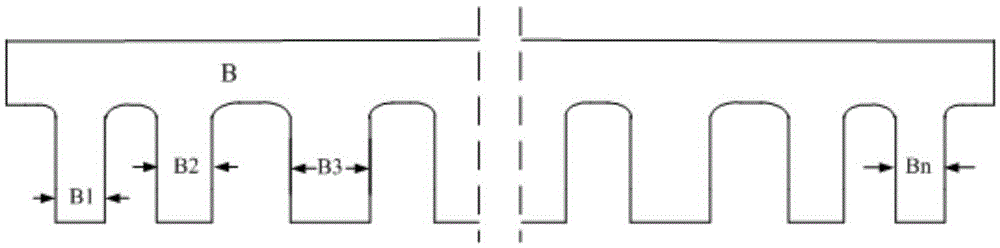

[0062] Such as figure 1As shown, the tobacco leaf shred method for improving the organoleptic quality of tobacco of the present invention includes unpacking, splitting, adding moisture to the sheet, storing leaves, shredding, adding shreds, drying, flavoring, and blending processes. Among them, the unpacking machine opens the outer package of the reconstituted tobacco bale with a size of (1100×700×700) mm. The lamination direction of the reconstituted tobacco leaf is perpendicular to the material conveying direction, and the long side of the cigarette bale is parallel to the conveying direction. The cigarette pack is transported to the slicing bin by the conveying belt, and the slicing machine divides the cigarette bale into several small pieces from top to bottom along the lamination direction of the cigarette bale, and each small piece is still a combination of several cigarette sheets. The 2 loose rake rollers located in the middle of the feeding bin and the bottom of the l...

Embodiment 2

[0070] The unpacking machine opens the outer package of the reconstituted tobacco bale with a size of (1100×700×700) mm. The lamination direction of the reconstituted tobacco leaf is perpendicular to the material conveying direction, and the short side of the cigarette bale is parallel to the conveying direction. The cigarette packs are transported to the slicing bin by the conveyor belt, and the slicing machine divides the cigarette packs into several small pieces along the lamination direction of the cigarette packs from top to bottom. The 4 loose rake rollers located in the middle of the feeding bin and the bottom of the lifting belt further loosen the pre-loose reconstituted tobacco leaf pieces and transport them to the moisture-resurgence feeding barrel to control the moisture content of the reconstituted tobacco leaves to 19% and the temperature at the outlet Be 44 ℃, add sugar material in the ratio of 0.75% simultaneously. The reconstituted tobacco leaves after moisture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com