Charging barrel overturning device and method for overturning charging barrel

A technology of turning device and barrel, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc. It can solve the problems of difficult handling, high difficulty, and high labor intensity, so as to reduce the labor intensity of workers, save time in operation, and The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

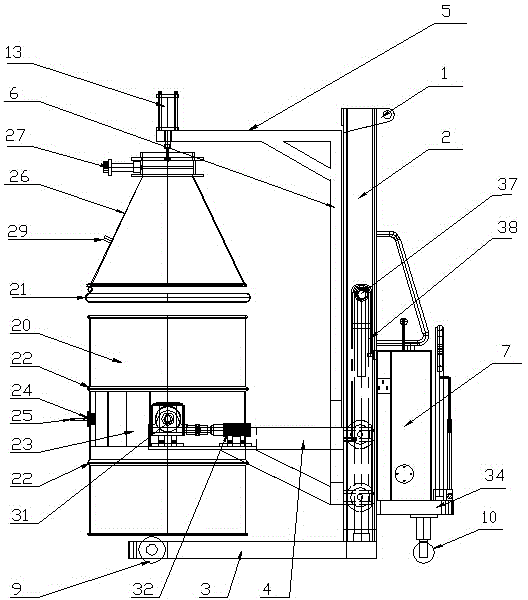

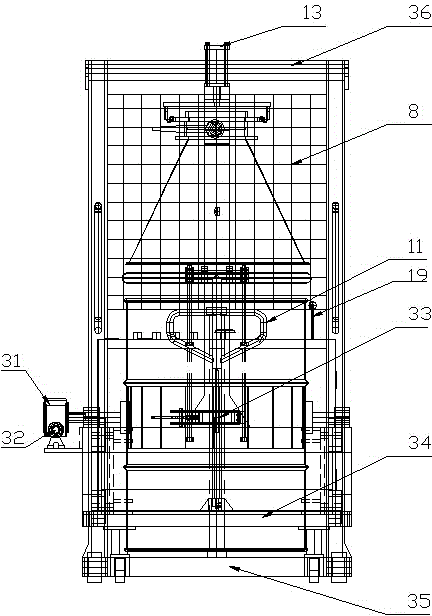

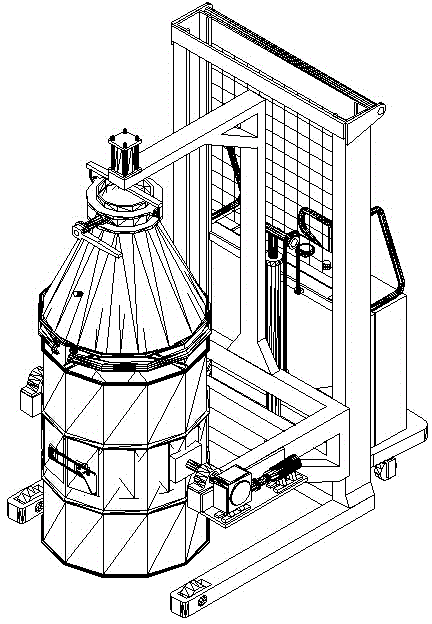

[0029] Example 1 Such as Figure 1-5 Shown: A bucket turning device, including a gantry frame 1 welded by vertical channel steel 2 on both sides, an upper beam 36 and a lower beam 35, and a front fork 3 welded vertically to the bottom of the channel steel 2 on both sides And be installed on the walking wheel 9 of front fork 3 front ends; Both sides channel steel 2 rear bottoms are welded with operation platform 34, and operation platform 34 both sides bottoms are equipped with universal wheel 10, and operation platform 34 middle parts are equipped with articulated handle 11, close to The articulated handle 11 is provided with a handle return spring damping cylinder 33; both sides of the rear end of the concave lifting fork 4 above the front fork 3 are provided with pulleys nested in the cavities of the left and right channel steel 2, and the bottom of the main oil cylinder 12 is installed In the middle of the lower beam 35, the sprockets 37 are symmetrically installed on bot...

Embodiment 2

[0031] Example 2 Such as Figure 1-5 Shown: adopt the method for turning over the material bucket of a kind of material bucket turning device described in embodiment 1, comprising:

[0032] [1] Manipulate the handle 11 hinged with the rear platform of the vehicle frame 1, move the bucket turning device to the storage place of the fully loaded bucket 20, insert the front fork 3 at the bottom of the gantry frame 1 into the bottom of the fully loaded bucket 20, Enclose the holding hoop 23 composed of two semi-circular arc iron plates between the two anti-slip protrusions 22 in the middle of the fully loaded material barrel 20, and lock the lock 24 and the buckle 25 to clamp the fully loaded material. barrel 20;

[0033] [2] Press the lid lowering button 16 to control the lid oil cylinder 13, so that the funnel-shaped lid 26 is separated from the hook of the hanging ear 28 and moves downward. Tighten the funnel-shaped bung 26 and bung to seal tightly;

[0034] [3] Operate the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com