Novel magnetic biological filtration pool

A biofilter and anoxic biofilter technology, applied in the field of new magnetic biofilters, can solve the problems of poor growth of organisms lack of nutrition, new magnetic filters have never appeared, filter blockage and backwash frequency, etc., to achieve adhesion Good performance, improved microbial utilization, enhanced removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

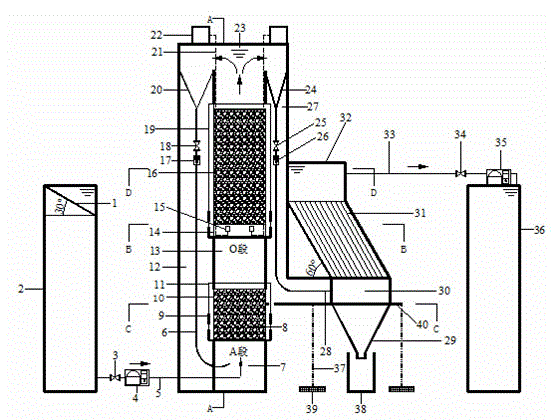

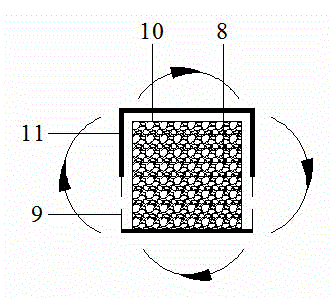

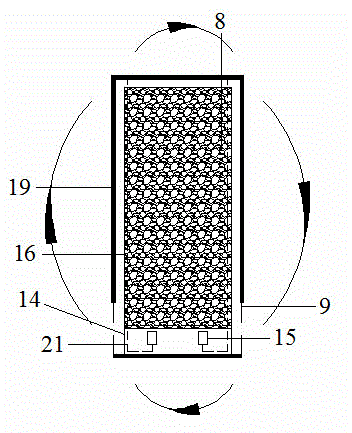

[0033] Embodiment 1: as Figure 1-7 As shown, a new type of magnetic biofilter includes a water inlet grid 1, a water inlet tank 2, a valve in front of the pump 3, a water inlet pump 4, a water inlet pipe 5, the main part of the integrated equipment, an outlet pipe 33 after sedimentation, and a water outlet pipe 33 after sedimentation. Water outlet valve 34, outlet water disinfection device 35, outlet water collection tank 36, the main part of the integrated equipment is composed of the main part of the bioreactor, the accessory part of the bioreactor, and the sedimentation part. The main part of the bioreactor and the sedimentation part pass through the main part of the integrated equipment The plexiglass walls on the right are welded tightly together,

[0034] The main part of the bioreactor consists of a water flow mixing zone 7, a section A anoxic biological filter 10, a return pipe tank 12, an ascending water buffer zone 13, an O section aerobic aerated biological filter ...

Embodiment 2

[0040] Embodiment 2: as Figure 1-7 As shown, a new type of magnetic biofilter includes a water inlet grid 1, a water inlet tank 2, a valve in front of the pump 3, a water inlet pump 4, a water inlet pipe 5, the main part of the integrated equipment, an outlet pipe 33 after sedimentation, and a water outlet pipe 33 after sedimentation. Water outlet valve 34, outlet water disinfection device 35, outlet water collection tank 36, the main part of the integrated equipment is composed of the main part of the bioreactor, the accessory part of the bioreactor, and the sedimentation part. The main part of the bioreactor and the sedimentation part pass through the main part of the integrated equipment The plexiglass walls on the right are welded tightly together,

[0041]The main part of the bioreactor consists of a water flow mixing zone 7, a section A anoxic biological filter 10, a return pipe tank 12, an ascending water buffer zone 13, an O section aerobic aerated biological filter 1...

Embodiment 3

[0049] Embodiment 3: as Figure 1-7 As shown, a new type of magnetic biofilter includes a water inlet grid 1, a water inlet tank 2, a valve in front of the pump 3, a water inlet pump 4, a water inlet pipe 5, the main part of the integrated equipment, an outlet pipe 33 after sedimentation, and a water outlet pipe 33 after sedimentation. Water outlet valve 34, outlet water disinfection device 35, outlet water collection tank 36, the main part of the integrated equipment is composed of the main part of the bioreactor, the accessory part of the bioreactor, and the sedimentation part. The main part of the bioreactor and the sedimentation part pass through the main part of the integrated equipment The plexiglass walls on the right are welded tightly together,

[0050] The main part of the bioreactor consists of a water flow mixing zone 7, a section A anoxic biological filter 10, a return pipe tank 12, an ascending water buffer zone 13, an O section aerobic aerated biological filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com