Reusing treatment method for printing and dyeing wastewater

A technology for printing and dyeing wastewater and treatment methods, which is applied in textile industrial wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve the problems of increased difficulty in industrial wastewater treatment, membrane fouling and rapid flux decline, Short service life and other issues, to achieve the effect of simple structure, increased specific surface area, and low infrastructure cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

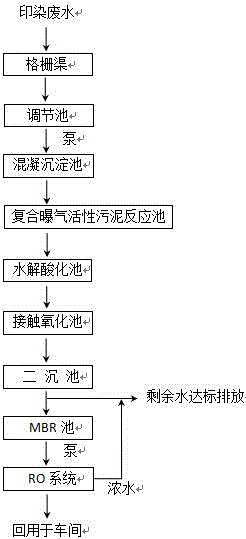

[0029] Such as figure 1 Shown: the method of the present invention can ensure that the treated effluent reaches the standard stably, and has been successfully operated on many engineering examples. The specific process is as follows:

[0030] (a) After the printing and dyeing wastewater passes through the grid, part of the suspended matter is removed and enters the adjustment tank. The specific operation after entering the coagulation sedimentation tank from the adjustment tank is: put flocculants and coagulants into the printing and dyeing wastewater, and pass through the mixer in the reaction zone. Stop the stirring effect, and control the stirring force and stirring time of the mixer, fully mix the flocculant, coagulant and wastewater, under the function of adsorption, net capture and bridge support of the flocculant and coagulant, the pollutants in the wastewater The flocs will eventually form flocs, and then in the separation area, the flocs will sink to the bottom of th...

Embodiment 2

[0037] On the basis of embodiment 1, change the running parameter in each operation, specifically as follows:

[0038] (a) After the printing and dyeing wastewater passes through the grid, part of the suspended matter is removed and enters the adjustment tank. The specific operation after entering the coagulation sedimentation tank from the adjustment tank is: put flocculants and coagulants into the printing and dyeing wastewater, and pass through the mixer in the reaction zone. Stop the stirring effect, and control the stirring force and stirring time of the mixer, fully mix the flocculant, coagulant and wastewater, under the function of adsorption, net capture and bridge support of the flocculant and coagulant, the pollutants in the wastewater The flocs will eventually form flocs, and then in the separation area, the flocs will sink to the bottom of the tank by their own gravity, and will be discharged into the sludge thickening tank by the scraper and suction machine that wo...

Embodiment 3

[0045] On the basis of embodiment 1, change the running parameter in each operation, specifically as follows:

[0046] (a) After the printing and dyeing wastewater passes through the grid, part of the suspended matter is removed and enters the adjustment tank. After entering the coagulation sedimentation tank from the adjustment tank, the specific operation is as follows: put flocculants and coagulants into the printing and dyeing wastewater, and pass through the agitator in the reaction zone. Stop the stirring effect, and control the stirring force and stirring time of the mixer, fully mix the flocculant, coagulant and wastewater, under the action of the adsorption, net capture and bridge function of the flocculant and coagulant, the pollutants in the wastewater With the initial coagulation of chemicals, flocs are finally formed, and then in the separation area, the flocs sink to the bottom of the tank by their own gravity, and are discharged into the sludge thickening tank by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com