Negative ion ceramic glaze and method for preparation of negative ion ceramic brick from negative ion ceramic glaze

A technology of ceramic glaze and negative ions, applied in the field of ceramic processing, can solve the problems of small distribution, difficulty in breathing, toxicity, etc., and achieve the effect of removing peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

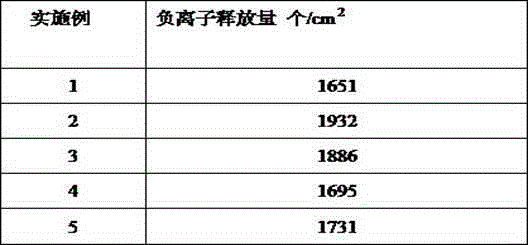

Examples

Embodiment 1

[0022] A negative ion ceramic glaze is composed of the following components in percentage by weight:

[0023] Kaolin 33%, potassium feldspar 18%, nano-titanium dioxide 8%, nano-magnesia tourmaline powder 8%, nano-lithium tourmaline powder 20%, praseodymium trioxide 7%, water 6%;

[0024] Its preparation method comprises the following steps:

[0025] Mix the prepared raw materials into a ball mill for 12 hours, remove iron, sieve and sieve 220 mesh to make negative ion ceramic glaze; glaze the dried ceramic body by spraying glaze, and the glaze surface The thickness is 0.35mm, fired at a temperature of 1000°C for 8 hours, and a negative ion glazed tile with health care and environmental protection functions is obtained.

Embodiment 2

[0027] A negative ion ceramic glaze is composed of the following components in percentage by weight:

[0028] Kaolin 15%, potassium feldspar 21%, nano-titanium dioxide 5%, nano-magnesia tourmaline powder 12%, nano-lithium tourmaline powder 28%, praseodymium trioxide 12%, water: 7%;

[0029] Its preparation method comprises the following steps:

[0030] Put the prepared raw materials into a ball mill and mill them for 58 hours, remove iron, sieve and sieve 250 mesh with 0.5% remaining, and make negative ion ceramic glaze; glaze the dried ceramic body by spraying glaze, the glaze thickness 0.55mm, fired at a temperature of 1280°C for 2 hours, a negative ion glazed tile with health care and environmental protection functions was obtained.

Embodiment 3

[0032] A negative ion ceramic glaze is composed of the following components in percentage by weight:

[0033] Kaolin 25%, potassium feldspar 15%, nano-titanium dioxide 9%, nano-magnesia tourmaline powder 5%, nano-lithium tourmaline powder 33%, praseodymium trioxide 5%, water: 8%;

[0034] Its preparation method comprises the following steps:

[0035] Put the prepared raw materials into a ball mill and mill them for 36 hours, remove iron, sieve and 230 mesh sieve with 0.7% remaining, and make negative ion ceramic glaze; glaze the dried ceramic body by spraying glaze, the glaze thickness 0.45mm, fired at a temperature of 1150°C for 5 hours, a negative ion glazed tile with health care and environmental protection functions was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com