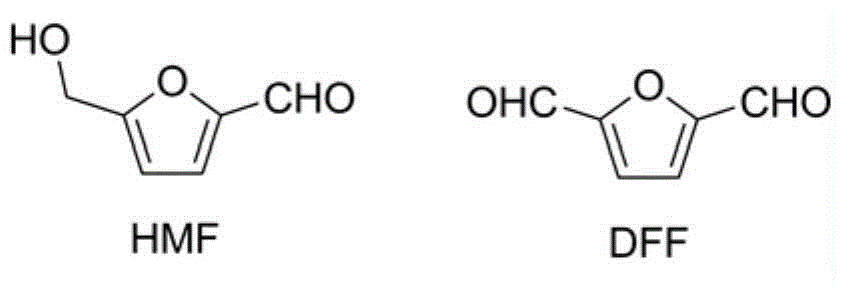

Method for separating 5-hydroxymethyl furfural and 2,5-diformylfuran mixture

A technology of diformylfuran and hydroxymethylfurfural, applied in the direction of organic chemistry, can solve problems such as difficult to achieve effective separation, and achieve the effects of easy scale-up, pollution reduction, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

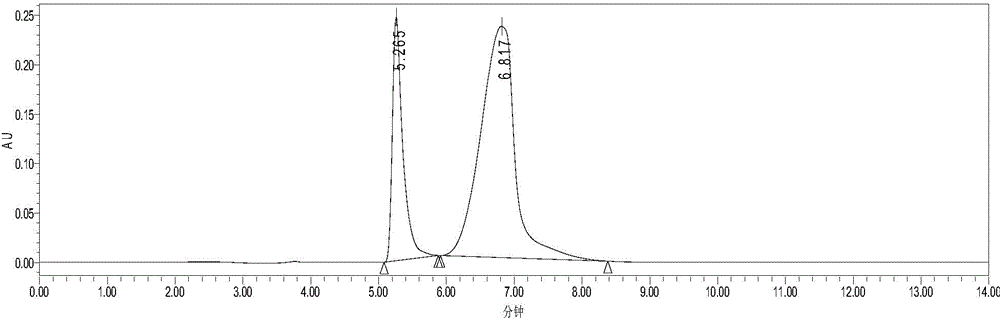

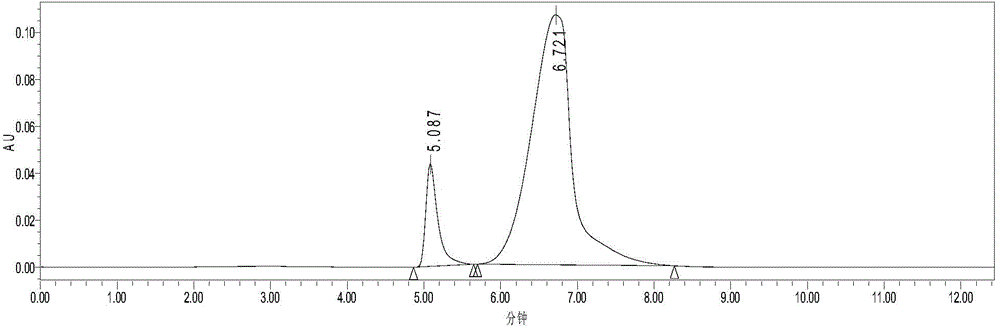

[0025] The mixture of HMF (content 24%) and DFF (content 76%) was dissolved in ethyl acetate so that the concentrations were 0.67mg / mL and 2.07mg / mL respectively (see figure 1 , the retention times of HMF and DFF are 5.27min and 6.82min respectively), add 2 times the volume of DES (choline chloride: glycerol=1:2, mol / mol), stir at room temperature and 400r / min for 10min, divide Phase, liquid chromatography analysis showed that HMF and DFF concentrations in ethyl acetate were 0.12mg / mL and 1.00mg / mL (see figure 2 ), remove ethyl acetate under reduced pressure to obtain DFF with a purity of 89%.

Embodiment 2

[0027] The mixture of HMF (content 24%) and DFF (content 76%) was dissolved in ethyl acetate so that the concentrations were 0.67mg / mL and 2.07mg / mL respectively, and 5 times the volume of DES (choline chloride: glycerol =1:2, mol / mol), stirred at room temperature and 400r / min for 10min, phase separation, liquid chromatography analysis showed that the concentrations of HMF and DFF in ethyl acetate were 0.07mg / mL and 0.84mg / mL respectively, and the Ethyl acetate was removed under reduced pressure to obtain DFF with a purity of 93%.

Embodiment 3

[0029] The mixture of HMF (content 24%) and DFF (content 76%) was dissolved in ethyl acetate so that the concentrations were 0.67mg / mL and 2.07mg / mL respectively, and 1 volume of DES (choline chloride: urea =1:2, mol / mol), stirred at room temperature and 400r / min for 10min, separated phases, and liquid chromatography analysis showed that the concentrations of HMF and DFF in ethyl acetate were 0.34mg / mL and 1.97mg / mL respectively. Ethyl acetate was removed under reduced pressure to obtain DFF with a purity of 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com