Spherical calcium alginate gel micro-particle preparation method

A calcium alginate and gel technology, which is applied in the field of medical materials, can solve the problems of easy clogging of microfluidic chips, irregular shapes of calcium alginate gel particles, etc., and achieves resistance to gravity and interface, viscosity and surface tension. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

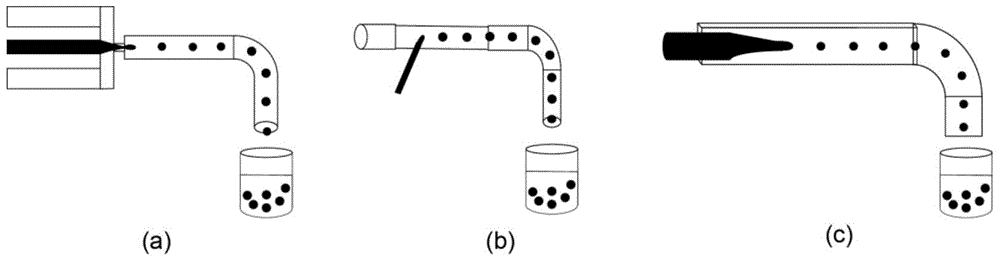

[0028] The preparation method of spherical calcium alginate gel particles provided by the present invention is prepared by using a microfluidic chip, comprising the following steps:

[0029] (1) Preparation of the oil phase: uniformly mix the ethanol solution of the soluble calcium salt and the continuous phase matrix containing the surfactant to obtain a homogeneous mixture; the homogeneous mixture is obtained by solvent evaporation method to obtain the in-situ-formed calcium salt-containing nano The oil phase of the grains; the oil phase per milliliter contains 0.04-0.1 mmol of calcium salt. The surfactant is a non-ionic surfactant, preferably Span 80, and its content is between 2 and 5 wt%.

[0030] When mixing, in order to be more uniform, ultrasonic mixing can be used; the calcium salt, preferably calcium chloride or calcium nitrate, ensures good solubility; the continuous phase matrix is preferably liquid paraffin, salad oil, silicone oil and other non-polar organic so...

Embodiment 1

[0035] A method for preparing spherical calcium alginate gel particles is prepared by using a microfluidic chip, comprising the following steps:

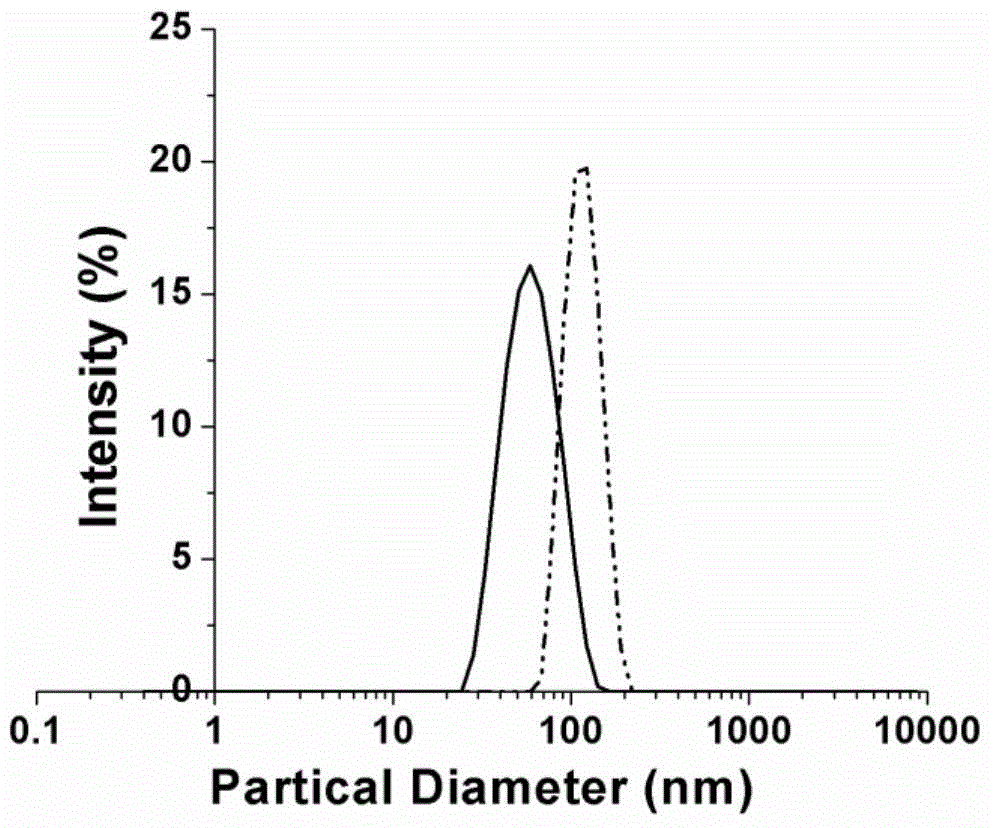

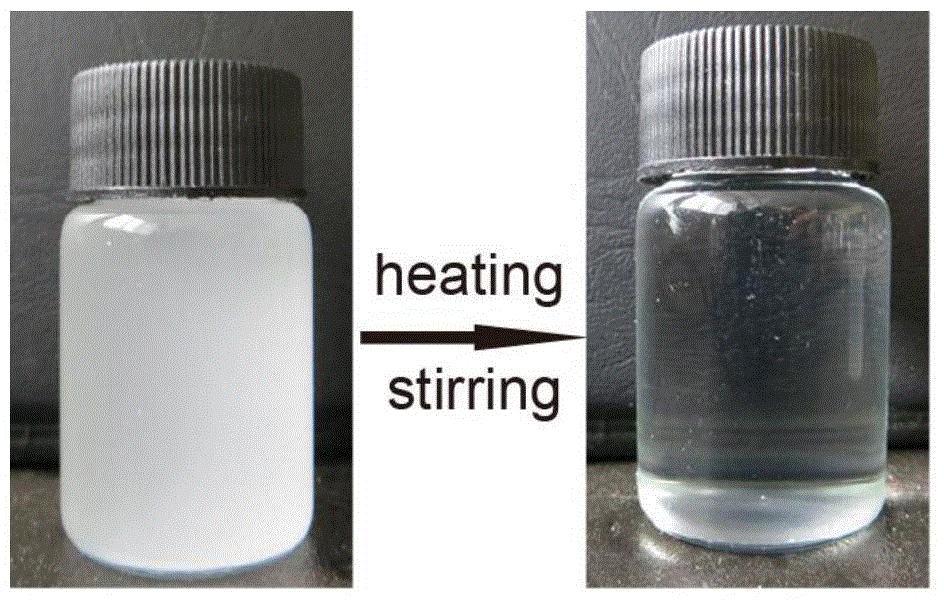

[0036] (1) Preparation of oil phase: weigh 0.04g of anhydrous CaCl 2 Dissolve in about 3mL of ethanol, ultrasonically dissolve or stir to dissolve, then add to 10mL liquid paraffin containing 2wt% Span 80, ultrasonically mix or stir well, then magnetically stir overnight at 60°C to completely volatilize the ethanol, After cooling to room temperature, an oil phase containing calcium salt nanoparticles formed in situ is prepared; each milliliter of the oil phase contains 0.04 mmol of calcium salt. Determination of CaCl in the prepared oil phase by dynamic light scattering 2 The size distribution of the nanoparticles is as figure 1 As shown by the middle solid line, the average particle diameter is 50 nm, and the polydispersity index is 0.2. The photo of the oil phase before ethanol volatilization is as follows figure 2 As shown o...

Embodiment 2

[0043] A method for preparing spherical calcium alginate gel particles is prepared by using a microfluidic chip, comprising the following steps:

[0044] (1) Preparation of the oil phase: Weigh 0.11g of anhydrous Ca(NO 3 ) 2 Dissolve in about 4mL of ethanol, ultrasonically dissolve or stir to dissolve, then add to 10mL of salad oil containing 2.5wt% Span 80, ultrasonically mix or stir well, then magnetically stir overnight at 60°C to completely evaporate the ethanol , and then cooled to room temperature, the oil phase containing calcium salt nanoparticles formed in situ was prepared; the oil phase contained 0.07 mmol of calcium salt per milliliter. Ca(NO) in the prepared oil phase was determined by dynamic light scattering 3 ) 2 The size distribution of the nanoparticles is as figure 1 As shown by the middle dotted line, the average particle diameter is 110 nm, and the polydispersity index is 0.3.

[0045] (2) Preparation of spherical calcium alginate gel particles by mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com