Modified polyurethane filling material for tunnel and preparation method thereof

A filling material, polyurethane technology, applied in the field of polyurethane materials, can solve the problems of poor flame retardancy, poor mechanical properties of phenolic materials, easy to be weathered, etc., to meet construction requirements and environmental protection requirements, good expandability and mechanical properties, anti-corrosion Good shear and toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

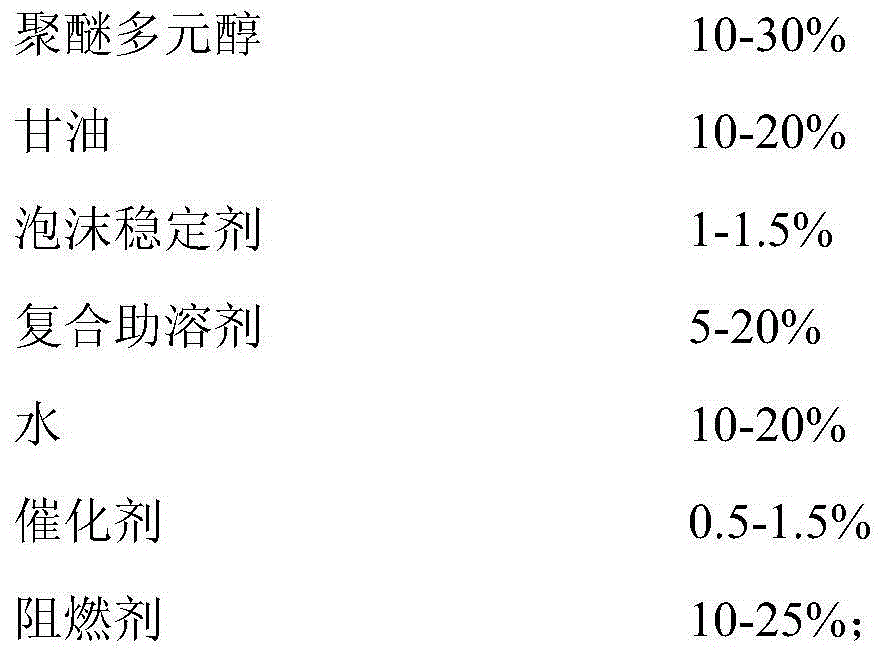

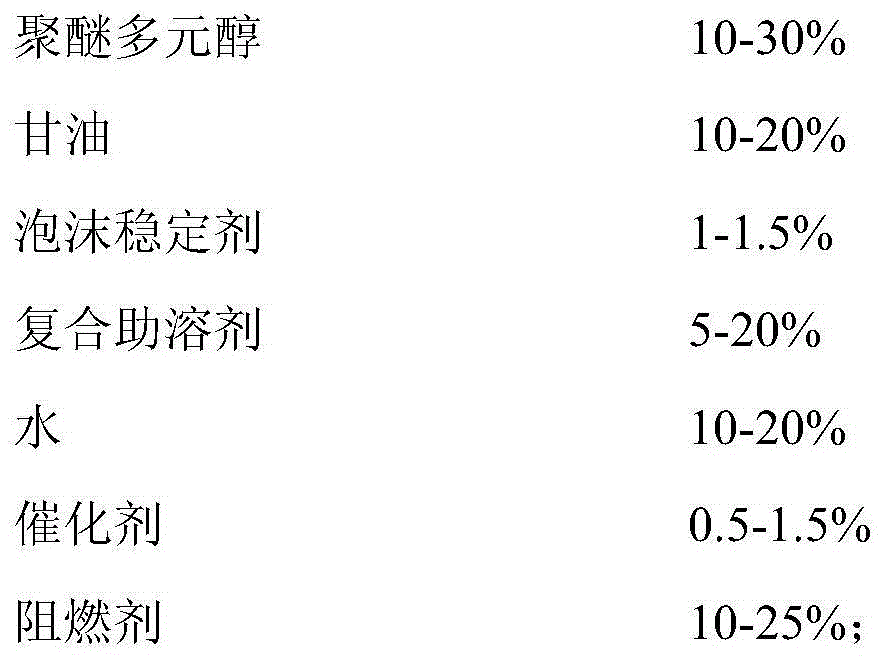

Method used

Image

Examples

Embodiment 1

[0027] (1) Prepare 100 kg of A component material: Weigh 30 kg of polyoxypropylene ether polyol with a functionality of 3 and a molecular weight of 3000, 16 kg of glycerin, 7 kg of OP-10, 807 kg of Tween, and 30 kg of Span Put 806 kg into the mixing kettle and stir evenly; 1 kg of AK-8872, 0.5 kg of triethylenediamine, 0.5 kg of pentamethyldiethylenetriamine, 20 kg of water, 12 kg of flame retardant, and stir evenly.

[0028] (2) Prepare 100 kg of component B materials: put 60 kg of weighed polymethylene polyphenyl polyisocyanate, 25 kg of diphenylmethane diisocyanate, and 15 kg of plasticizer into a mixing tank and stir evenly.

[0029] Mix and foam components A and B according to the weight ratio of A:B=1:1 to obtain the modified polyurethane filling material for the tunnel, and test the product index.

[0030] Molding core density: 60kg / m 3

[0031] Foaming multiple: 20

Embodiment 2

[0033] (1) Prepare 100 kilograms of component A materials: weigh 24 kilograms of polyoxypropylene ether polyols with a functionality of 3 and a molecular weight of 3000, 18 kilograms of glycerin, 7 kilograms of OP-10, 807 kilograms of Tween, and Put 806 kg into the mixing kettle and stir evenly; add 1 kg of AK-8872, 0.5 kg of triethylenediamine, 0.5 kg of pentamethyldiethylenetriamine, 20 kg of water, 16 kg of flame retardant, and stir evenly.

[0034] (2) Prepare 100 kg of component B materials: put 55 kg of weighed polymethylene polyphenyl polyisocyanate, 25 kg of diphenylmethane diisocyanate, and 20 kg of plasticizer into a mixing tank and stir evenly.

[0035] Mix and foam components A and B according to the weight ratio of A:B=1:1 to obtain the modified polyurethane filling material for the tunnel, and test the product index.

[0036] Molding core density: 50kg / m 3

[0037] Foaming multiple: 25

Embodiment 3

[0039] (1) Prepare 100 kg of component A material: weigh 25 kg of polyoxypropylene ether polyol with a functionality of 3 and a molecular weight of 3000, 15 kg of glycerin, 7 kg of OP-10, 807 kg of Tween, and Put 806 kg into the mixing kettle and stir evenly; 1 kg of AK-8872, 0.5 kg of triethylenediamine, 0.5 kg of pentamethyldiethylenetriamine, 20 kg of water, 18 kg of flame retardant, and stir evenly.

[0040] (2) Prepare 100 kg of component B materials: put 60 kg of weighed polymethylene polyphenyl polyisocyanate, 25 kg of diphenylmethane diisocyanate, and 15 kg of plasticizer into a mixing tank and stir evenly.

[0041] Mix and foam components A and B according to the weight ratio of A:B=1:1 to obtain the modified polyurethane filling material for tunnels, and test the product indicators.

[0042] Molding core density: 55kg / m 3

[0043] Foaming multiple: 22.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com