A heterocycle azo yellow disperse dye and a preparing method thereof

A heterocyclic azo yellow and disperse dye technology, applied in the direction of azo dyes, monoazo dyes, organic dyes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

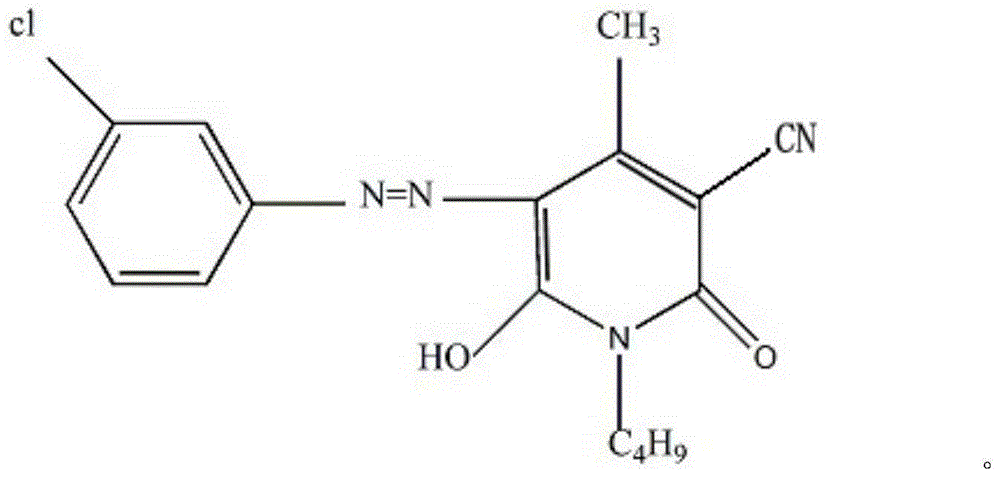

Embodiment 1

[0015] Add 1000 kilograms of water and 127.5 kilograms of m-chloroaniline into a 3000-liter pot, add 400 kilograms of 30% hydrochloric acid under stirring conditions, and add 500 kilograms of ice cubes to cool down to 0-3°C. Then add 200 kilograms of 30% sodium nitrite solution and carry out diazo reaction for 2 hours to obtain diazonium salt solution, add 1000 kilograms of water and 80 kilograms of soda ash in a 5000 liter pot, add 205 kilograms of N-butylpyridone under stirring conditions and stir After 0.5 hours, acid-precipitate with 8% hydrochloric acid, add 500 kg of ice cubes, and cool down to 5-8°C to obtain a coupling component. The diazonium salt solution was added to the coupling components within 1 hour, the pH value of the reaction mixture was adjusted to 0.5-1.5, the reaction was heated to 50°C for 4 hours and filtered, rinsed to neutrality, and 326 kilograms of dyes were obtained, and its molecular structural formula was:

[0016]

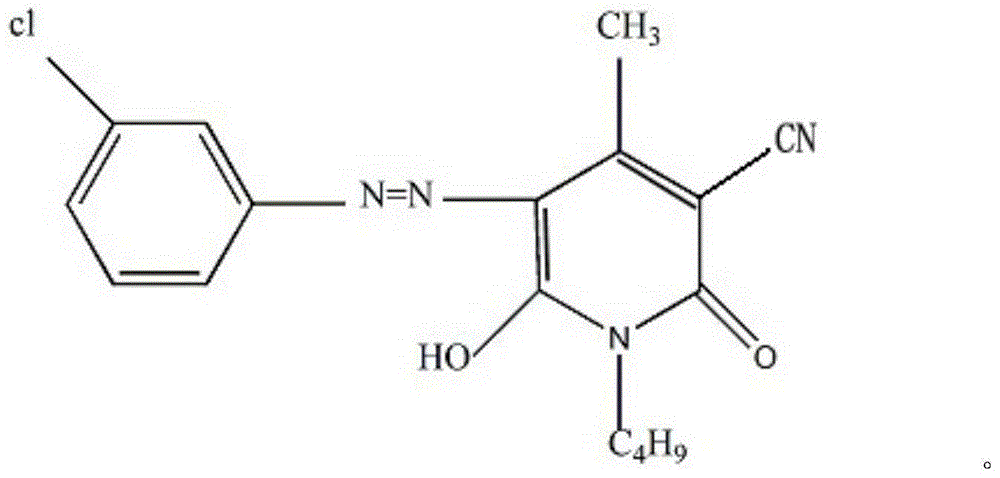

Embodiment 2

[0018] Add 1000 kg of water and 164 kg of orange-based GC into a 3000-liter pot, and add 100 kg of 30% hydrochloric acid under stirring conditions to completely dissolve the orange-based GC. Add 500 kilograms of ice cubes and be cooled to 0-3 ℃, then add 210 kilograms of 30% sodium nitrite solution to carry out diazonium reaction for 2 hours, obtain diazonium salt solution, add 1000 kilograms of water and 80 kilograms of soda ash in 5000 liters of pots, in Under stirring conditions, add 205 kg of N-butylpyridone and stir for 0.5 hour, then add 8% concentration of hydrochloric acid to carry out acid precipitation and add 500 kg of ice cubes to cool down to 5-8 DEG C to obtain a coupling component solution. The diazonium salt solution was added to the coupling components within 1 hour, the pH value of the reactant was adjusted to 0.5-1.5 and the reaction was performed for 4 hours, then the temperature was raised to 50°C for filtration, and 326 kilograms of dyes were obtained by r...

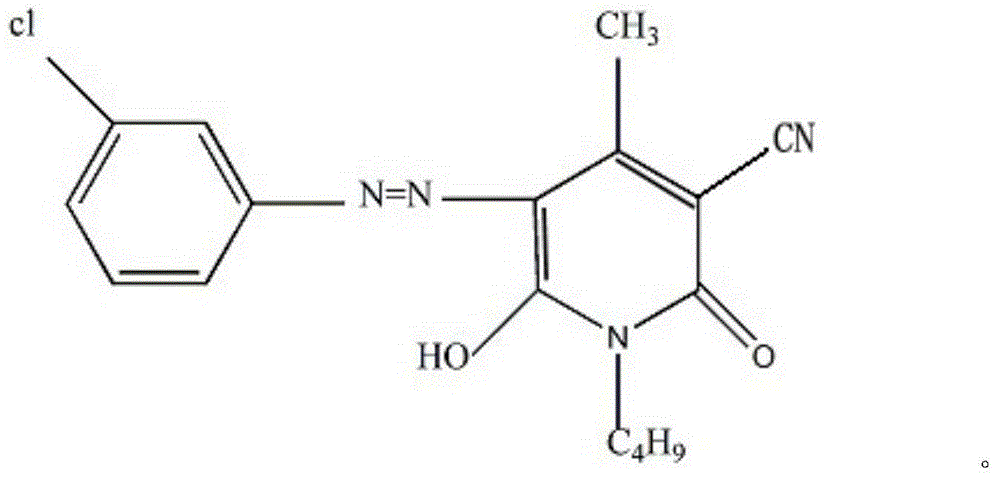

Embodiment 3

[0021] Add 1000 kilograms of water and 138 kilograms of m-nitroaniline into a 3000-liter pot, add 400 kilograms of 30% hydrochloric acid under stirring conditions, and stir for 0.5 hour, then add 500 kilograms of ice cubes to lower the temperature by 0-5°C. Then 160 kg of 30% sodium nitrite solution was added to carry out a diazo reaction for 2.5 hours to obtain a diazonium salt solution. Add 1000 kilograms of water and 80 kilograms of soda ash in a 5000-liter pot, add 205 kilograms of N-butylpyridone under stirring conditions and stir for 0.5 hour, then add 8% concentration hydrochloric acid for acid precipitation and add 400 kilograms of ice cubes to cool down to 6- 10 ° C, to obtain the coupling component, add the diazonium salt solution to the coupling component within 1.5 hours, adjust the pH value of the reactant to 0.5-1.5 and reflect for 5 hours, filter, and rinse to neutrality to obtain 326 kilograms of dyes. The structural formula is:

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com