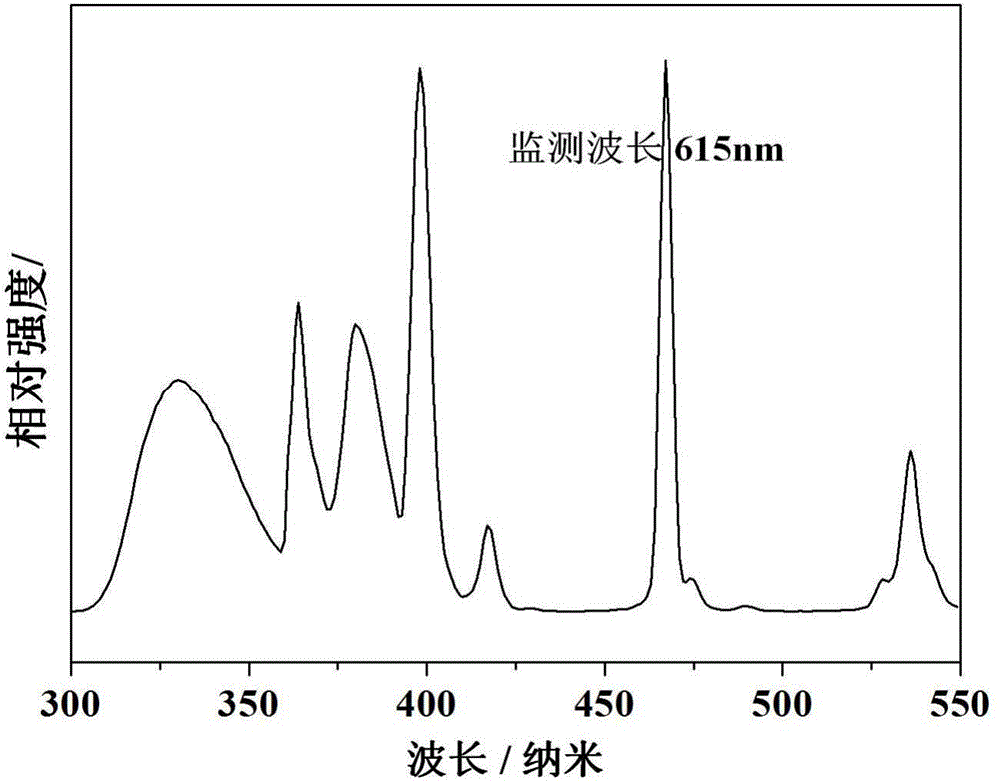

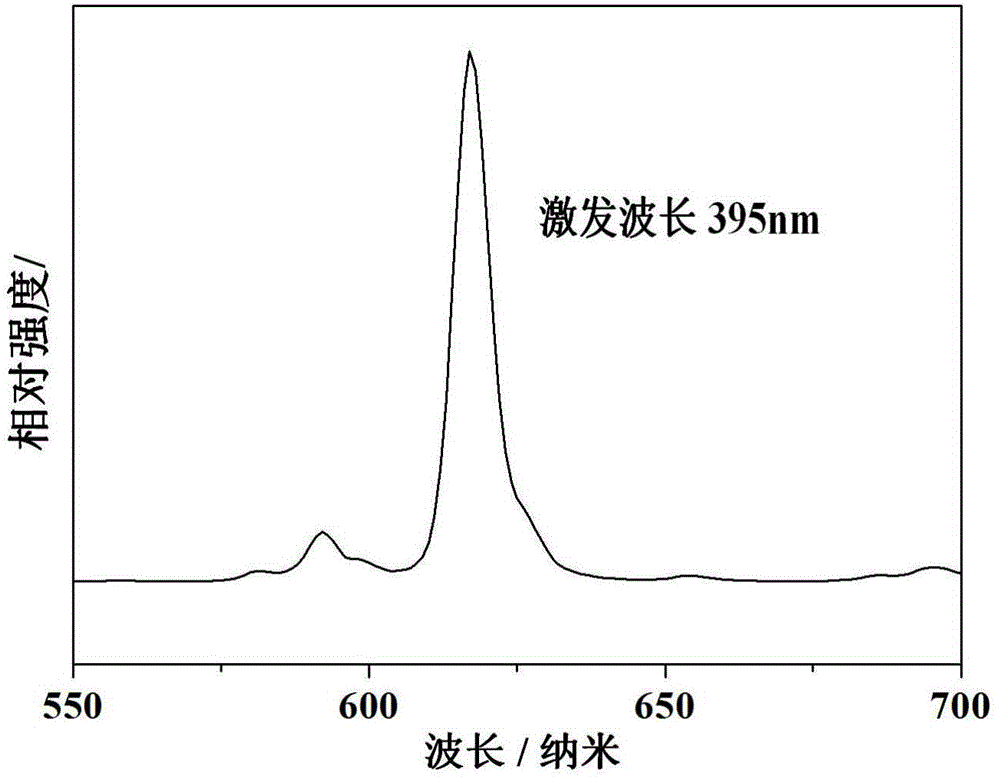

Li/Mg-codoped bi-perovskite red fluorescent powder and preparation method of same

A red phosphor, double perovskite technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low luminous intensity, insufficient red color purity, poor physical and chemical stability of host materials, etc., and achieve high luminous intensity. , The effect of good color purity and color rendering, short test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Composition is shown as 1# in table 1, and concrete preparation method comprises the following steps:

[0030] (1) the raw material Li 2 CO 3 , MgCO 3 、Na 2 CO 3 、WO 3 、Gd 2 o 3 、Eu 2 o 3 Weigh according to the stoichiometric ratio and raw material formula listed in Table 1, place in the alumina ball mill tank, add absolute ethanol and as the ball milling medium at the same time, and the alumina ball is used as the grinding ball;

[0031] (2) Put the ball mill jar on the ball mill, set the milling speed to 200r / min, and mill for 9 hours. The ball-milled slurry was taken out, put into a drying oven at 50°C, and dried for 12 hours.

[0032] (3) Calcining the dried and sieved mixture at high temperature, keeping it warm at 1300° C. for 4 hours, and cooling to room temperature with the furnace, to obtain the double perovskite red phosphor.

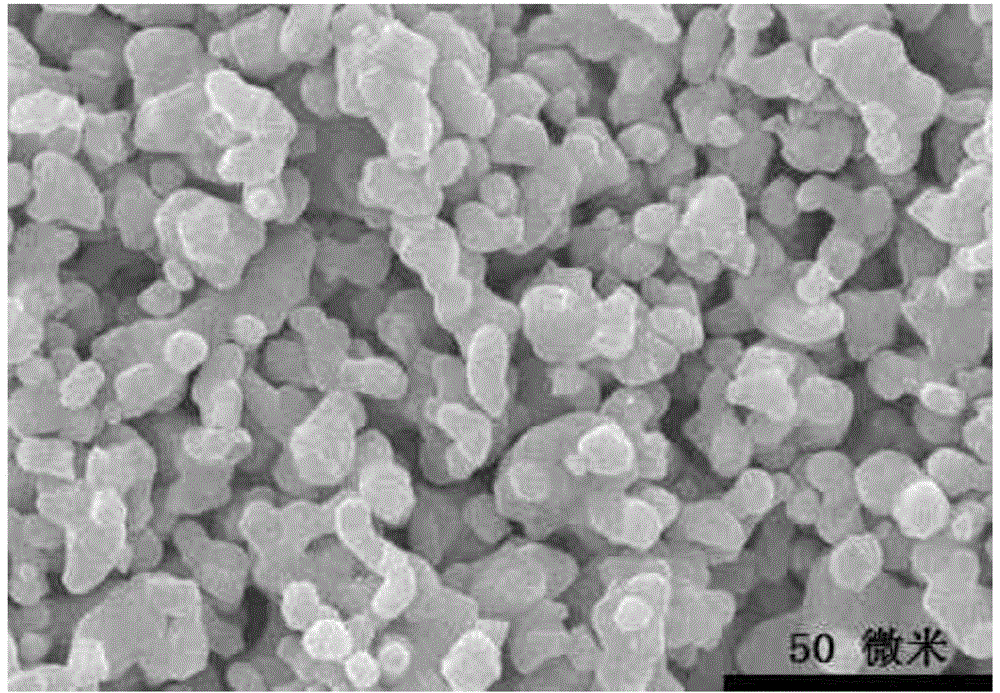

[0033] (4) Grinding the obtained product through a 200-mesh sieve, and then dry-pressing it into a thin disc with a powder ...

Embodiment 2

[0037]Composition is shown as 2# in table 1, and concrete preparation method comprises the following steps:

[0038] (1) the raw material Li 2 CO 3 , MgCO 3 、Na 2 CO 3 、WO 3 、Gd 2 o 3 、Eu 2 o 3 Weigh according to the stoichiometric ratio listed in Table 1 and the raw material formula, place in the alumina ball mill tank, add absolute ethanol and as the ball milling medium at the same time, and the alumina ball is used as the grinding ball;

[0039] (2) Put the ball mill jar on the ball mill, set the milling speed to 180r / min, and mill for 15 hours. The ball-milled slurry was taken out, put into a drying oven at 70°C, and dried for 10 hours.

[0040] (3) Calcining the dried and sieved mixture at high temperature, keeping it warm at 1200° C. for 5 hours, and cooling to room temperature with the furnace, to obtain the double perovskite red phosphor.

[0041] (4) Grinding the obtained product through a 200-mesh sieve, and then dry-pressing it into a thin disc with a pow...

Embodiment 3

[0045] Composition is shown as 2# in table 1, and concrete preparation method comprises the following steps:

[0046] (1) the raw material Li 2 CO 3 , MgCO 3 、Na 2 CO 3 、WO 3 、Gd 2 o 3 、Eu 2 o 3 Weigh according to the stoichiometric ratio listed in Table 1 and the raw material formula, place in the alumina ball mill tank, add absolute ethanol and as the ball milling medium at the same time, and the alumina ball is used as the grinding ball;

[0047] (2) Put the ball mill jar on the ball mill, set the milling speed to 140r / min, and mill for 18 hours. The ball-milled slurry was taken out, put into a drying oven at 100°C, and dried for 10 hours.

[0048] (3) Calcining the dried and sieved mixture at a high temperature, keeping the temperature at 1100° C. for 6 hours, and cooling down to room temperature with the furnace to obtain the double perovskite red phosphor.

[0049] (4) Grinding the obtained product through a 200-mesh sieve, and then dry-pressing it into a thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com