However, there are many defects and

biological safety hazards in this operation method.

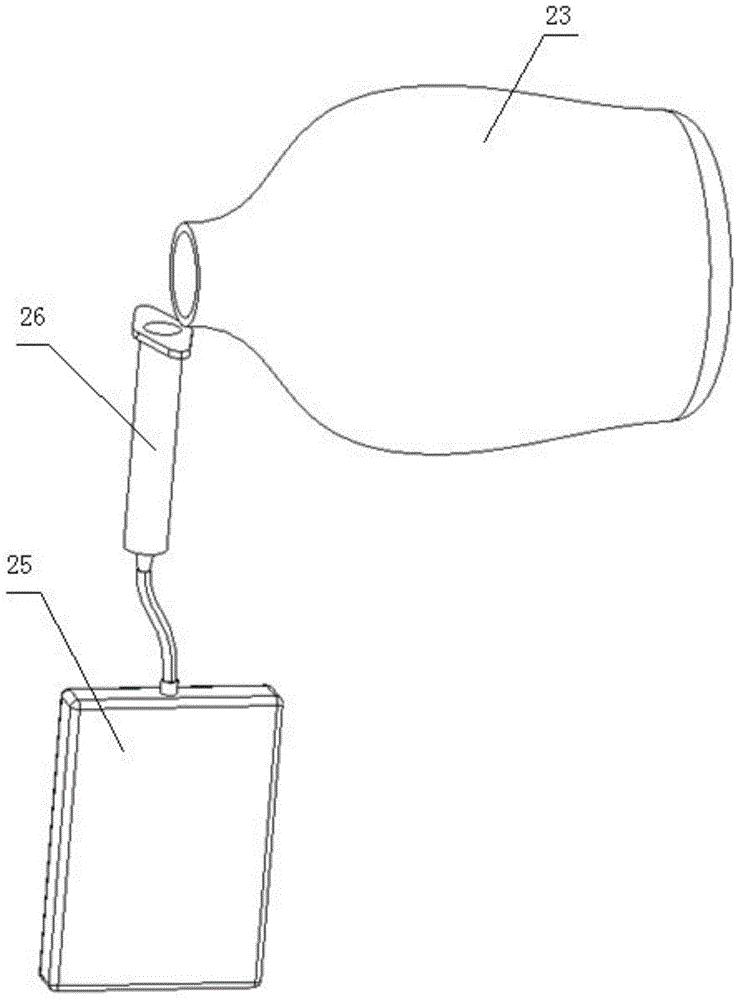

[0005] First, the "funnel" filling mode, the whole process is open operation, the patient's blood and samples are in direct contact with the air in the

biological safety cabinet during the whole filling process, there is a great

biological safety hazard[0006] Second, affected by the structure, since the capacity of the empty

barrel of the

syringe used as a "funnel" (currently commonly used is a 50 ml

syringe) is much smaller than the culture medium filled, and the liquid inlet and outlet pipes of the culture bag are relatively thin, the medium will flow from the empty

barrel of the

syringe The flow to the culture bag is slow, and the operator needs to manually pour the liquid several times, or continue to pour at a slow and uniform speed for about 5 minutes to completely pour a

bottle of 1

liter medium into the culture bag, which is inefficient

[0007] Third, since there are no disinfection measures on the outside of the culture medium

bottle, some

pollution particles attached to the

bottle are affected by the clean air flow in the

biosafety cabinet and its own gravity, during the process of pouring the culture medium into the empty syringe

barrel In the process, there is a possibility that it may fall from the bottle body and fall into the empty syringe barrel, thereby entering the culture bag with the culture medium to contaminate the sample. These particles are so small that they are almost invisible to the

naked eye, and there is currently no practical and effective preventive method

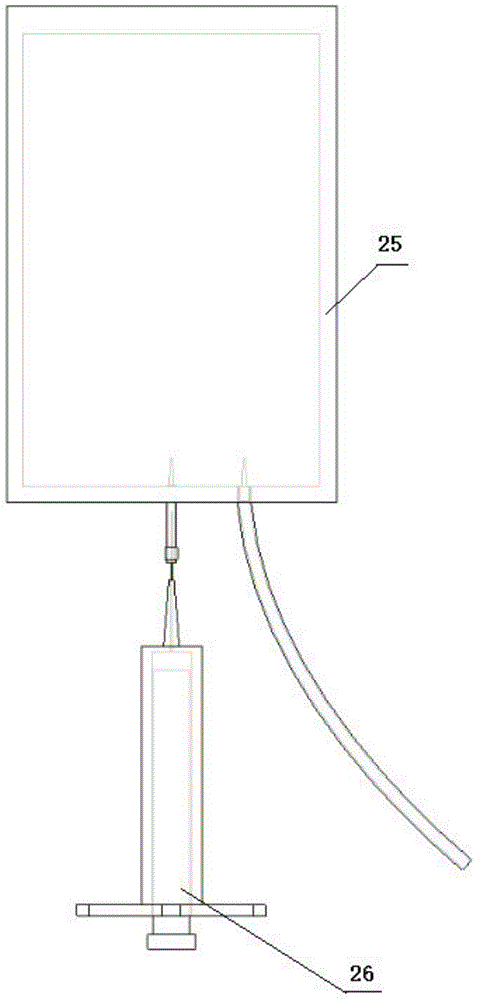

[0008] Fourth, since the connection between the inlet and outlet tubes of the culture bag and the needle head of the empty syringe is connected in a "straight-through" manner without any fixing device, the interface between the inlet and outlet tubes of the culture bag is often disconnected from the syringe during the filling process. The empty tube falls off, causing the liquid mixed with the patient's

plasma and samples (which are considered infectious in medicine) to spill on the

biosafety counter or even the laboratory floor, causing environmental

pollution and threatening the lives of other patients and operators

[0009] Fifth, since the entire filling process is manual, the operator holds the bottle all the way, and can only dispose of one bottle of culture medium at a time,

processing dozens of patient samples every day means lifting hundreds of 1L bottles Culture medium, the work is cumbersome, labor-intensive, and requires high precision in operation

During the filling process, if a little more culture medium is poured into the culture bag from the empty syringe barrel in time, the medium poured into the empty barrel may overflow from the upper part of the empty barrel, causing

sample contamination and environmental

pollution[0010] Sixth, the consumable "funnel" in the filling process is not a special device designed for biological treatment. Currently, the empty barrel part of the syringe is used to realize the function and can only be used once. Other parts of the syringe, such as the push

handle, Although needles and needle caps are not used, they have to be discarded as

medical waste, which wastes precious resources and pollutes the environment

[0015] Second, when the rubber stopper is repeatedly pierced by the syringe, its airtightness is greatly reduced, there is a hidden danger of liquid leakage, and it is impossible to ensure that the samples in the culture bag are completely isolated from the outside world

[0026] First, the structural characteristics of the rubber stopper make it possible for the needle to shed debris when the syringe is inserted. Once the shed rubber stopper particles are injected into the patient, they will cause different degrees of

vascular embolism, phlebitis, pulmonary

granuloma, and pyrogenic reaction in the patient. , allergic reactions, etc.

And because the

blood circulation of the

human body is a relatively closed pipeline, once the particles enter the human body, they will have potential, long-lasting, and greater harm.

[0027] Second, when the rubber stopper is repeatedly pierced by the syringe, its airtightness is greatly reduced, there is a hidden danger of liquid leakage, and it is impossible to ensure that the samples in the culture bag are completely isolated from the outside world

[0028] Third, if the

syringe needle has been contaminated with

bacteria, it will contaminate the entire sample in the culture bag

[0030] First, when the rubber stopper is repeatedly pushed by the syringe, its airtightness is greatly reduced, there is a hidden danger of leakage, and it is impossible to ensure that the samples in the culture bag are completely isolated from the outside world

[0031] Second, if the needle head of the empty syringe barrel has been contaminated by

bacteria, it will contaminate the entire sample in the culture bag

[0033] First, the samples in the culture bag are directly connected to the outside world, and the samples in the culture bag may be spilled

[0034] Second, if the needle head of the empty syringe barrel has been contaminated by

bacteria, it will contaminate the entire sample in the culture bag

There are also many defects and biological safety hazards in this method of operation.

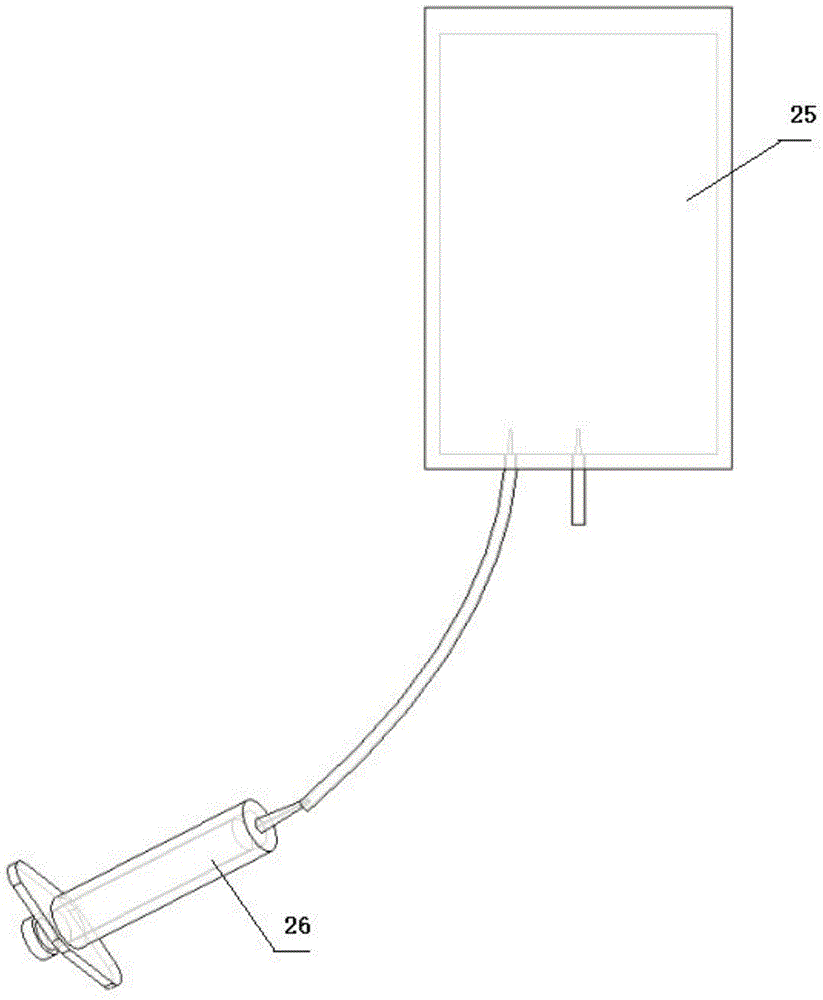

[0036] First, the direct pouring mode is adopted, the patient's blood and samples are in direct contact with the air in the biological safety cabinet, and the whole process is open operation, which has great biological safety hazards

[0037] Second, due to the thinner pipeline of the culture bag, the sample in the bag flows out slowly from the

cell culture bag, requiring the operator to pour it continuously, and it takes about 5 minutes for about 1

liter of sample to be completely poured into the

centrifuge tank, which is inefficient

[0038] Third, since there are no disinfection measures on the outside of the culture bag body, some of the contaminated particles attached to the bag body are detached from the bag body during the process of being poured into the

centrifuge tank under the action of the clean air flow in the biological safety cabinet and its own gravity. The possibility of falling into the

centrifuge tank may contaminate the matured samples. Since the pollution source is very small, it is almost invisible to the

naked eye, and it is difficult for the operator to detect it. If it is returned to the patient, it may cause bacterial infection, and in mild cases, fever and allergies will occur. In severe cases,

chills and

high fever may even threaten life

There is also a great risk of contracting certain infectious diseases (such as

hepatitis B,

hepatitis C, AIDS, etc.)

[0039] Fourth, since the entire pouring process is manual, the operator can only

handle the samples in one bag of culture bags at a time

The work is cumbersome, labor-intensive, and requires high precision in operation

If there is a little

carelessness during the pouring process, the sample can be spilled outside the centrifuge tank, polluting the environment in the biological safety cabinet and threatening the lives of other patients and operators

[0040] Through the search, no patent publications related to the

patent application of the present invention have been found

Login to View More

Login to View More  Login to View More

Login to View More