Surface anticorrosion treatment technology of carbon steel valve body for petroleum pipeline

A technology of oil pipeline and anti-corrosion treatment, applied in the field of surface treatment, can solve problems such as complicated steps, complicated winding process requirements, and inability to deal with large quantities of high-efficiency, so as to achieve the effect of improving service life and reducing maintenance and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

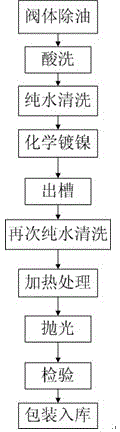

Image

Examples

Embodiment 1

[0026] The electroless nickel plating solution is composed of the following components by weight percentage: nickel sulfate 21.5%, lactic acid 28%, sodium acetate 21%, sodium hypophosphite 22%, propionic acid 2.2%, purified water 5.3%.

[0027] Use alkaline degreasing method to remove the oil on the surface of the valve body, then use 25% pickling solution for deep cleaning, and then rinse with pure water for 2 minutes. The valve body enters the plating tank filled with electroless nickel plating solution. The plating tank needs to be dust-proof and heat-preserved. The bonding force and surface hardness of the nickel-plated layer put the valve body into an electric heating oven, the temperature of the oven is controlled at 280°C, and it is cooled naturally after baking for 1.5 hours. In order to improve the surface finish, the valve body needs to be polished with polishing machine abrasive paste. Check whether the surface of the valve body is free of particles, no layers, no b...

Embodiment 2

[0029] The electroless nickel plating solution is composed of the following components by weight percentage: 22% nickel sulfate, 29% lactic acid, 22% sodium acetate, 23% sodium hypophosphite, 2.4% propionic acid, and 1.6% pure water.

[0030] Use alkaline degreasing method to remove the oil on the surface of the valve body, then use 25% pickling solution for deep cleaning, and then rinse with pure water for 3 minutes. The valve body enters the plating tank filled with electroless nickel plating solution. The plating tank needs to be dust-proof and heat-preserved. The bonding force and surface hardness of the nickel-plated layer put the valve body in an electric heating oven, the temperature of the oven is controlled at 290 ° C, and it is naturally cooled after baking for 1 hour. In order to improve the surface finish, the valve body needs to be polished with a polishing machine grinding paste. Check whether the surface of the valve body is free of particles, no layers, no bump...

Embodiment 3

[0032] The electroless nickel plating solution is composed of the following components by weight percentage: nickel sulfate 21%, lactic acid 26%, sodium acetate 21%, sodium hypophosphite 24%, propionic acid 2%, purified water 6%.

[0033] Use alkaline degreasing method to remove the oil on the surface of the valve body, then use 25% pickling solution for deep cleaning, and then rinse with pure water for 3 minutes. The valve body enters the plating tank filled with electroless nickel plating solution. The plating tank needs to be dust-proof and insulated, and the temperature is kept at 92°C. The bonding force and surface hardness of the nickel-plated layer put the valve body in an electric heating oven, the temperature of the oven is controlled at 300 ° C, and it is naturally cooled after baking for 1 hour. In order to improve the surface finish, the valve body needs to be polished with a polishing machine grinding paste. Check whether the surface of the valve body is free of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com