Device and method for fishing drill dregs

An overshot and slag drilling technology, which is used in earth-moving drilling, wellbore/well components, etc., to achieve the effect of ensuring rapid hole formation, reducing wear and reducing the risk of in-hole accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

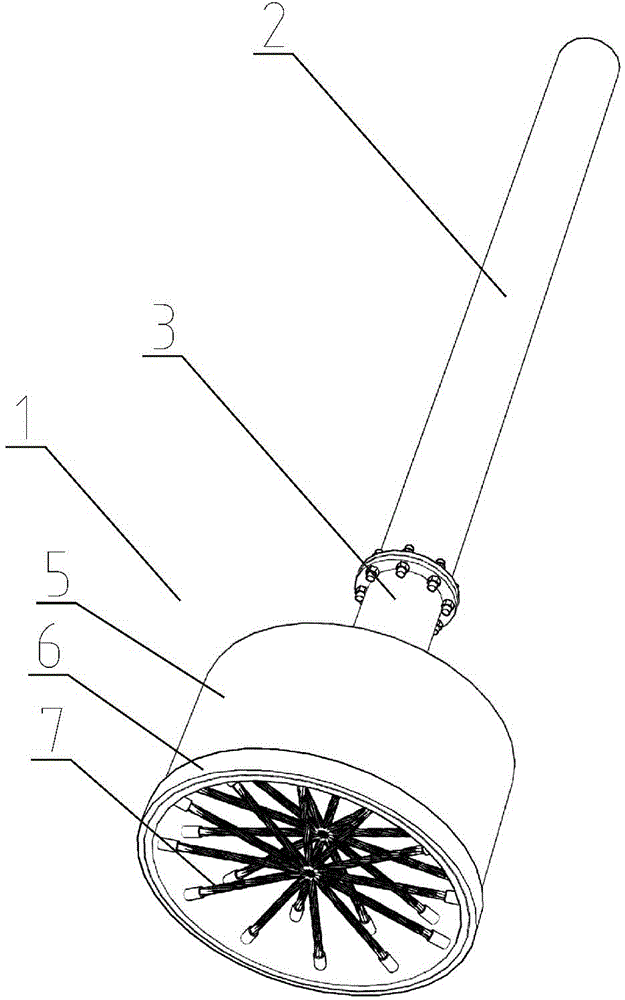

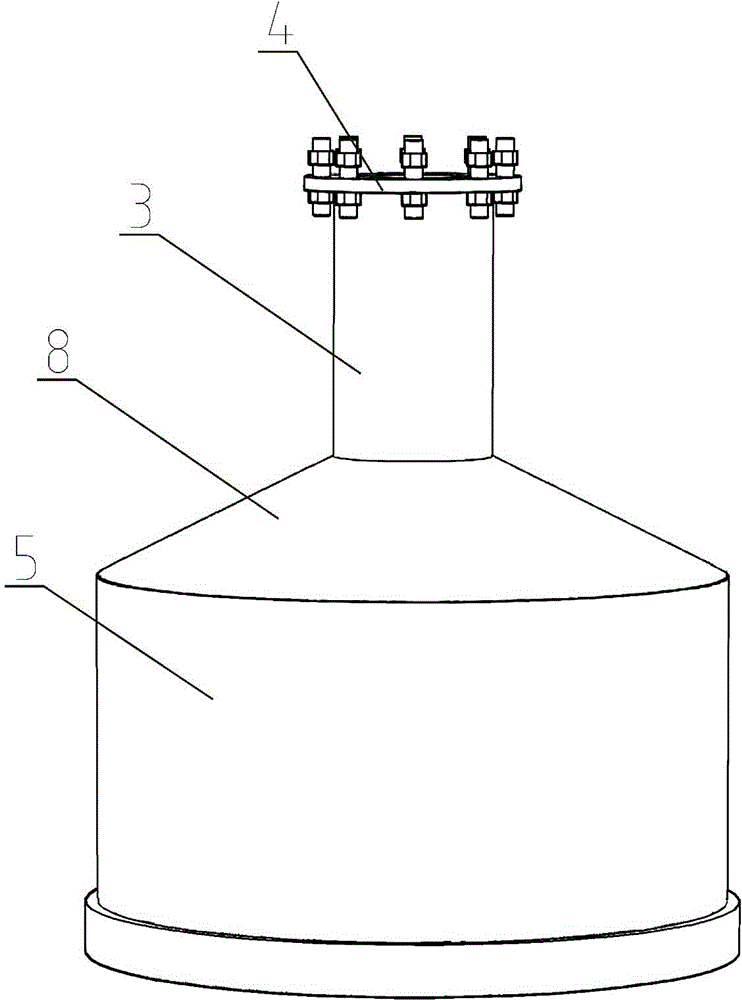

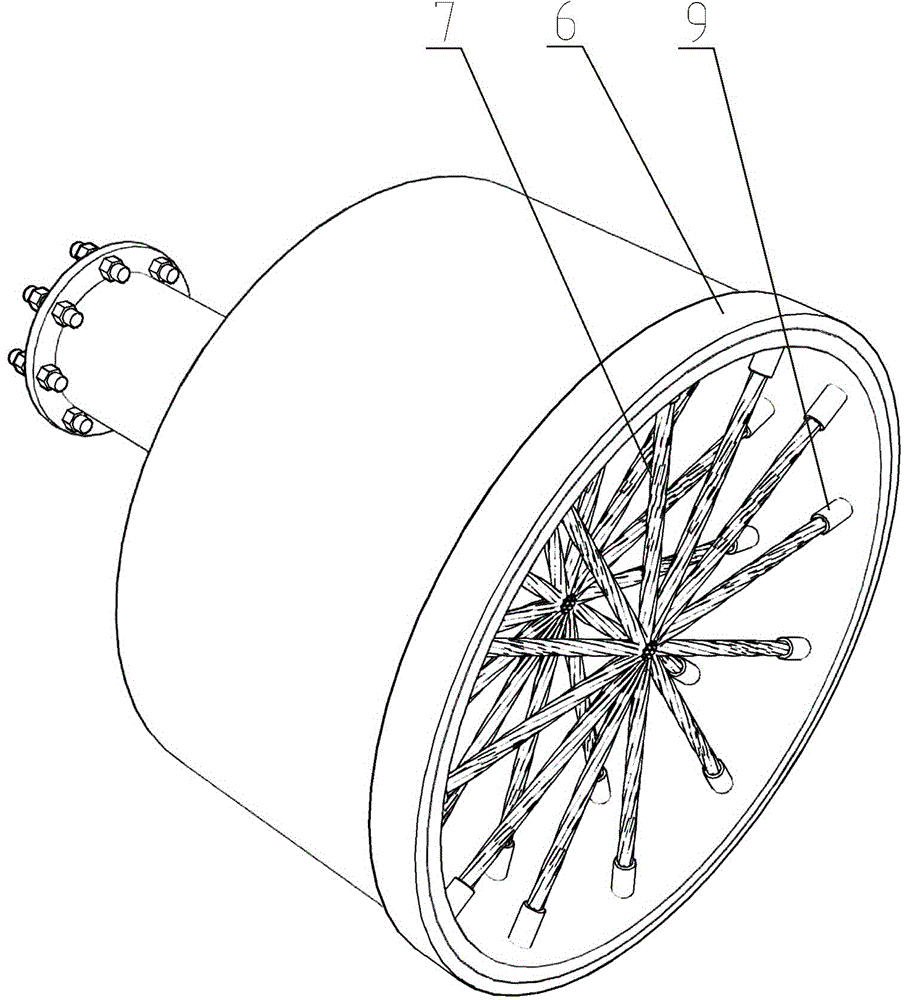

[0029] like Figure 1~4 Among them, a drilling slag fisher, the fisher 1 includes a cylinder 5, and the cylinder 5 adopts Q 235 The steel plate is rolled and welded, the thickness of the steel plate is 2.5cm, the diameter is 3 / 4 of the pile diameter, the height of the cylinder 5 is 1.2m, and the cylinder 5 is mainly the storage space for drilling slag salvage. The lower end of the cylinder body 5 is open, and a conical cap 8 is arranged at the upper end of the cylinder body 5, and the conical cap adopts Q 235 The steel plate is cut, rolled and welded, the conical cap and the cylinder 5 are welded into a whole, the top of the conical cap 8 is connected with the connecting rod 3 of Zhongtong, the connecting rod 3 is made of a short drill pipe, and the diameter of the cylinder 5 is greater than the diameter of the connecting rod 3. A support wire 7 is provided at a position close to the bottom of the cylinder body 5 . The support wire 7 is a steel strand.

[0030] In a prefer...

Embodiment 2

[0036] On the basis of embodiment 1, a kind of drilling slag dredging method adopting above-mentioned drilling slag dredge comprises the following steps:

[0037] 1. Stop drilling after encountering large-size drilling slag. When drilling difficulties, drill pipe jumping, slurry temperature rise and other phenomena occur during drilling, it indicates that the pile has entered the large-sized boulder and floating gravel layer. At this time, stop drilling and pull out the drill pipe.

[0038] 2. Replace the overshot. After the drill pipe is pulled up, the drill bit is replaced with the slag catcher of the present invention, and then the hole is drilled again until the top of the large-diameter slag;

[0039] Three, rotary cutting extrusion slag removal. After the overshot touches the large-sized drilling slag, the drill pipe will not continue to sink. At this time, the low-speed, slow-rotation and slow-pressure operation mode is adopted, for example, the speed is lower than 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com