A Raman test system and test method for in-situ testing LED stress

A technology of in-situ testing and testing system, which is applied in the direction of measuring the change force of optical properties of materials when they are stressed, and can solve problems such as high Raman spectroscopy, weak Raman scattering signal intensity, and inability to solve stress testing. , to avoid interference and improve the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

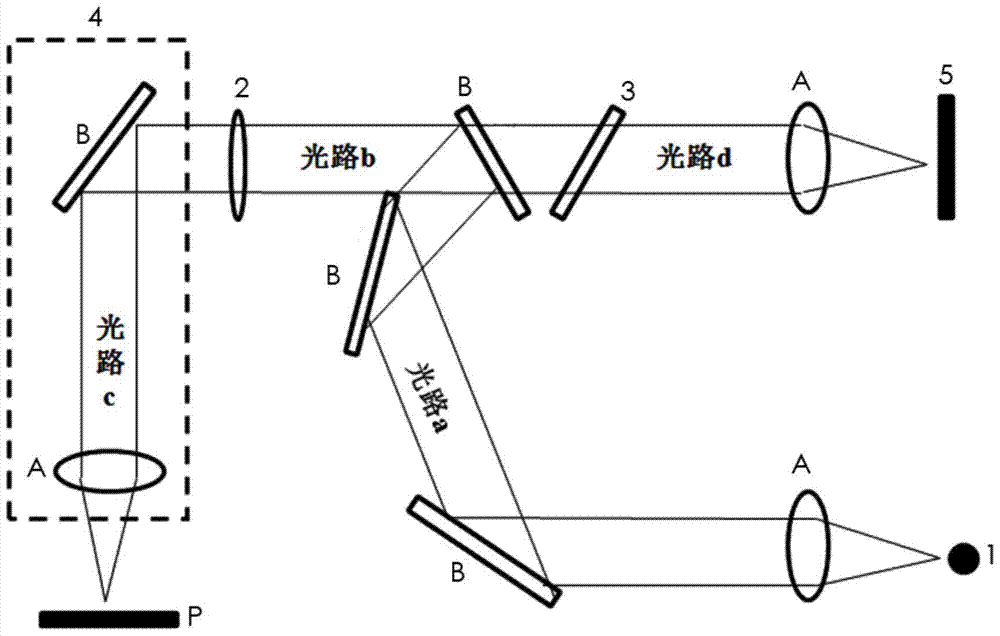

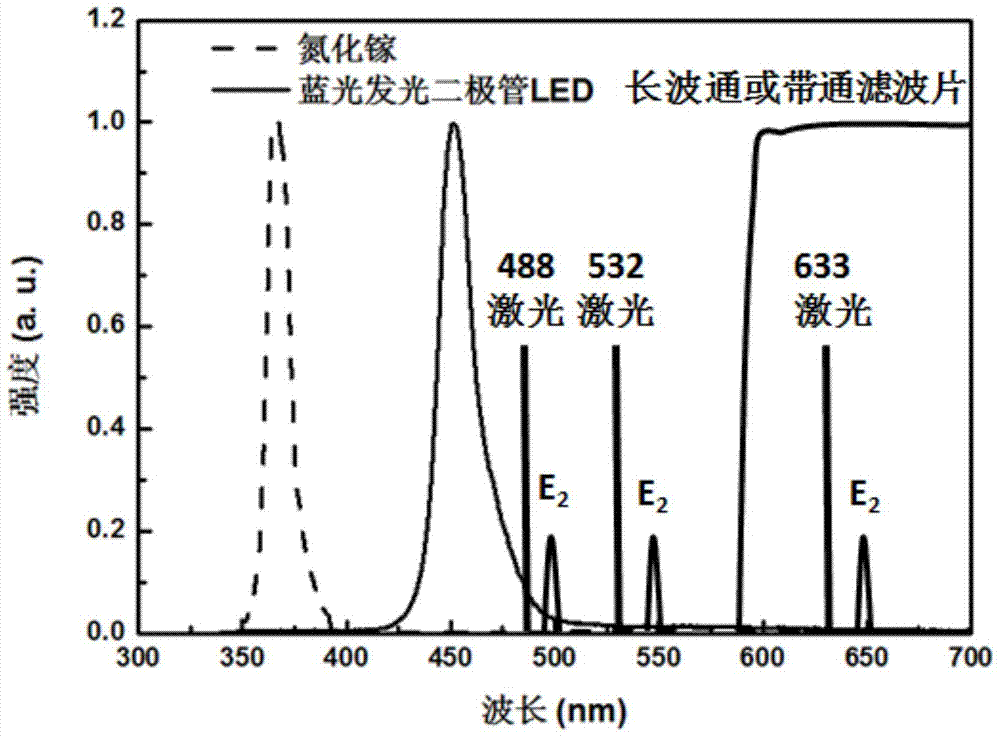

[0023] see figure 1 , the embodiment of the Raman test system for in-situ testing of LED stress in the present invention is provided with a laser 1, an optical path system a / b / c / d, a long-wave pass or band-pass filter 2, a Raman filter 3, a microscope 4, and a CCD 5 The long-wave pass or bandpass filter 2 is located at the front end of the microscope light path in the Raman light path, the rear end of the microscope light path, the front end of the Raman filter, the rear end of the Raman filter or the front end of the CCD, etc., preferably the rear end of the microscope light path, And combined with a laser whose wavelength is far away from the LED light emission spectrum.

[0024] The long-wave pass or band-pass filter 2 allows signals with a wavelength greater than 600nm to be filtered, and the long-wave pass or band-pass filter is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com